Denture Liner, Denture Liner Kit And Method For Making A Denture Liner

a denture and gum liner technology, applied in the field of denture compositions, can solve the problems of inability to adjust to the change in the shape of the gums, the gap between the denture and the gums begins to form, and the fit between the denture and the alveolar ridge worsens, so as to improve the separability, improve the adhesive action, and strengthen the bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

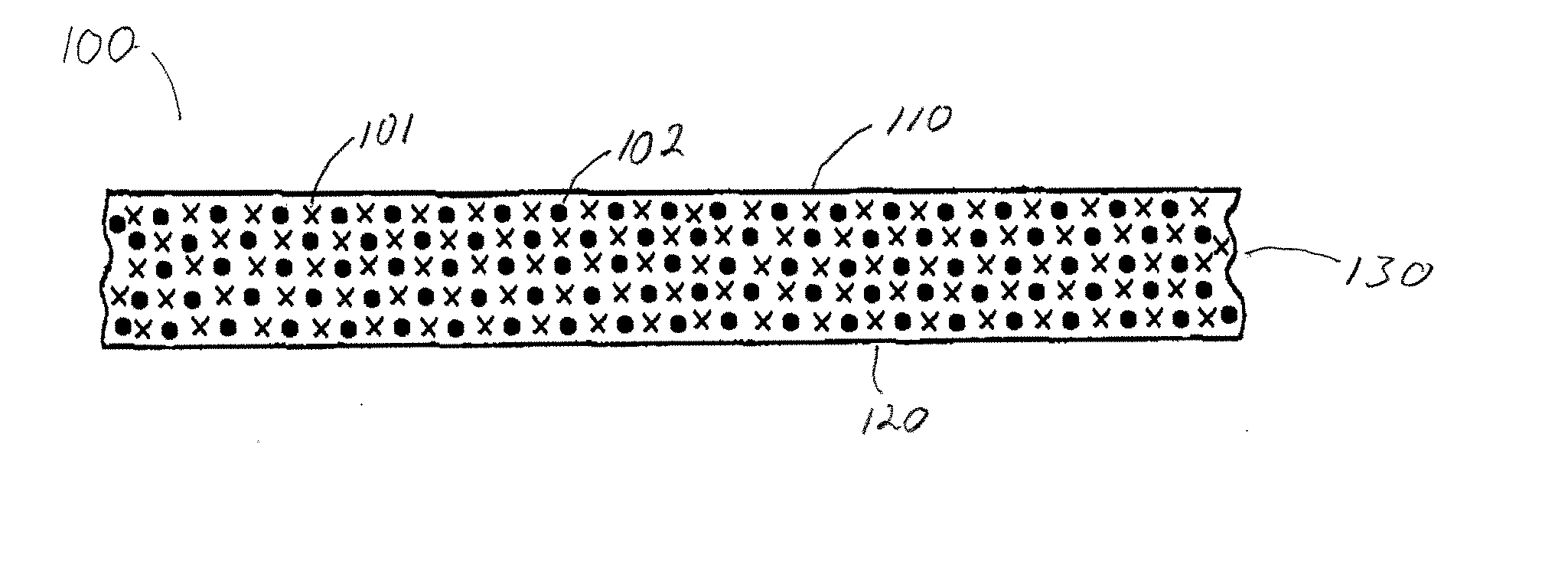

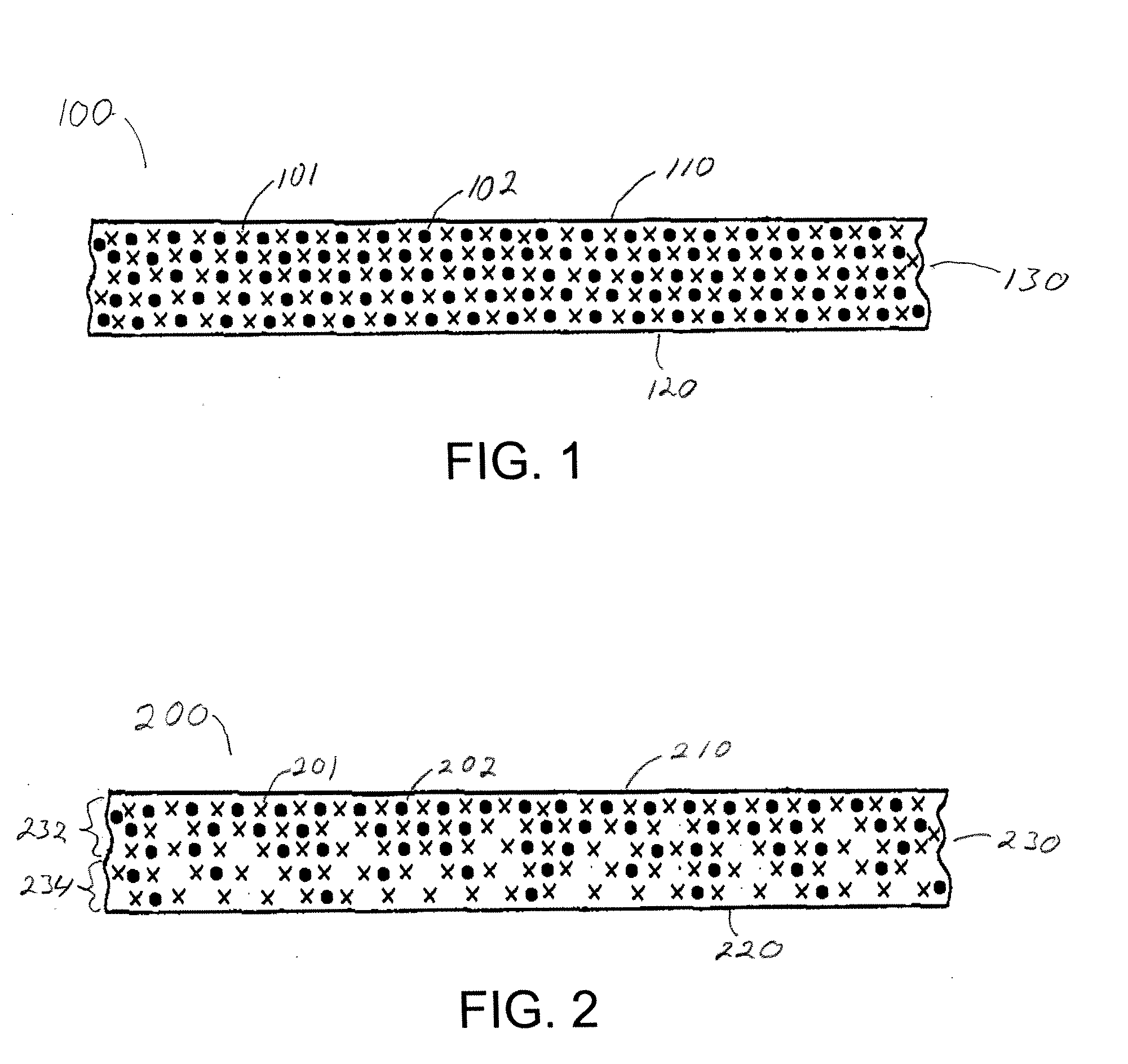

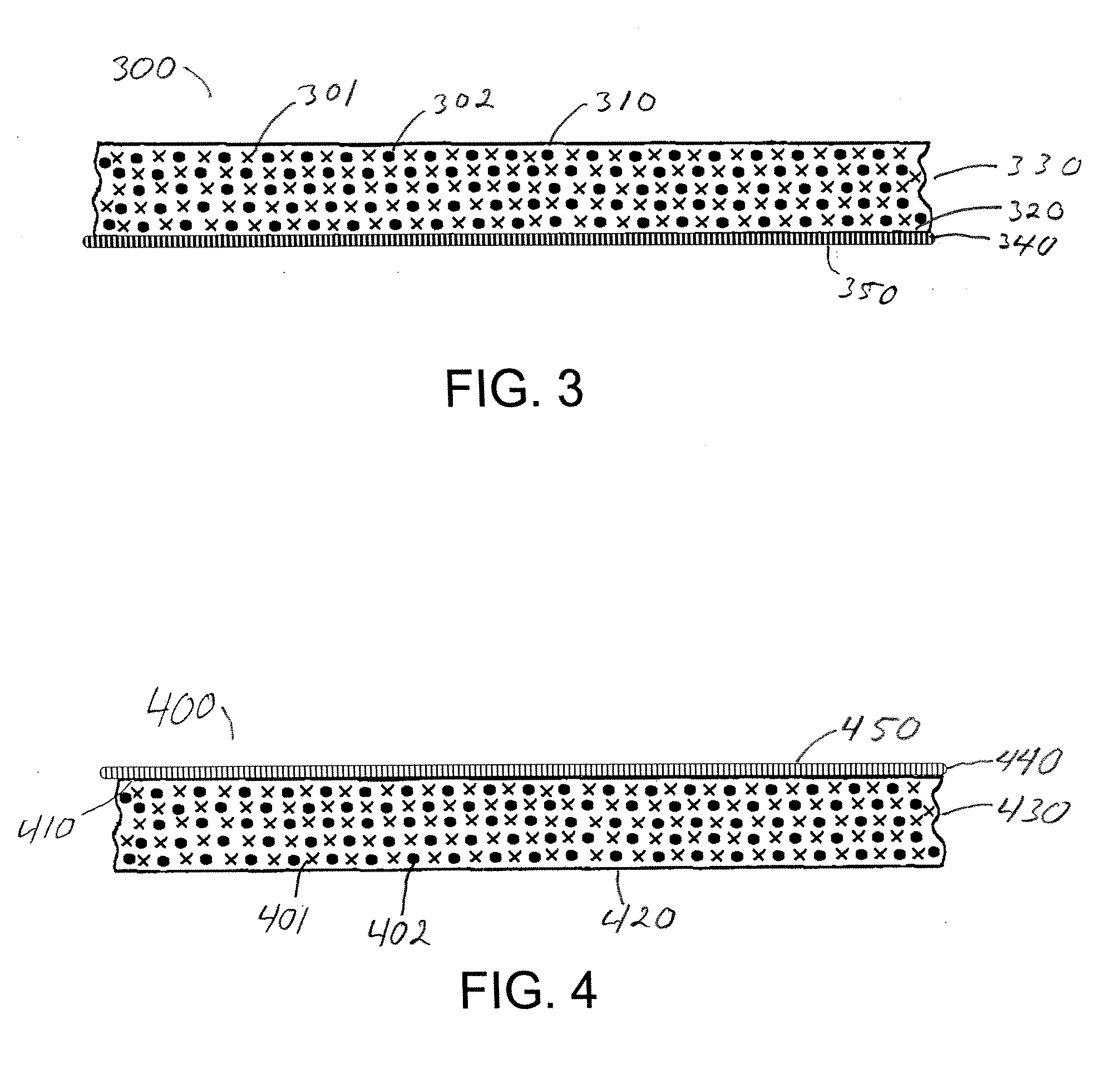

Image

Examples

embodiment

PREFERRED EMBODIMENT

[0101] In a preferred embodiment of the present invention a denture liner is formed comprising a self-supporting and shape-retaining layer that comprises a volume of a hydrophobic polymer component, preferably from about 40% to about 65% by weight of the layer, that inhibits the liner from absorbing moisture and enables the denture liner to maintain its integrity. The layer further comprises a volume of a hydrophilic polymer component, preferably from about 30% to about 40% by weight of the layer, that hydrates a surface of the liner when exposed to moisture. The layer still further comprises a volume of a plasticizer component, preferably from about 16% to about 20% by weight of the layer, that plasticizes the denture liner and enables a surface of the liner to adhere to the denture base when dry. The layer also comprises a volume of a filler component, preferably from about 1% to about 10% by weight of the layer, that inhibits the plasticizer from leaching out ...

example 1

[0122] A denture liner was prepared by combining components in amount as listed in Table 1. This liner was made by blending all the components in a Hobart7 mixer. A pre weighed sample, was sandwiched between two release papers. Using a hydraulic Carver7 press, and a shim gap of 0.5 mm, the sample was compressed at 10 tons for 20 seconds at 210 deg. F. The compressed composition was then cut by hand to the shape of the denture liner.

TABLE 1IngredientContent (wt. %)PEMA21Triacetin28BPBG (Morflex 190)21Polyox15NaCMC15

[0123] The polymer component of this denture liner is PEMA, which functions as a main film former, vehicle, gap filler and adhesive carrier. The plasticizer component consists of triacetin and BPBG. The adhesive component includes polyox and NaCMC. Specifically, polyox is a tackifier and a mucoadhesive. NaCMC is a swelling component and a mucoadhesive.

[0124] The denture liner of this example cures and sets as a result of the action of the plasticizers. This makes the de...

example 2

[0127] A denture liner is prepared by combining components in amounts as listed in Table 2 in the same manner as the liner in Example 1.

TABLE 2IngredientContent (wt. %)PEMA35Triacetin17.5BPBG (Morflex 190)17.5Polyox15NaCMC15

[0128] This denture liner also contains a trace level of ethyl alcohol, which is added to make the material more flowable. The other components of this denture liner perform the same functions as in the liner of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com