Ferrous seal sliding parts and producing method thereof

a technology of sliding parts and ferrous seals, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of insufficient heat crack resistance and abrasion resistance, oil leakage, and increase in material cost in view of material yield, and achieve excellent heat crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

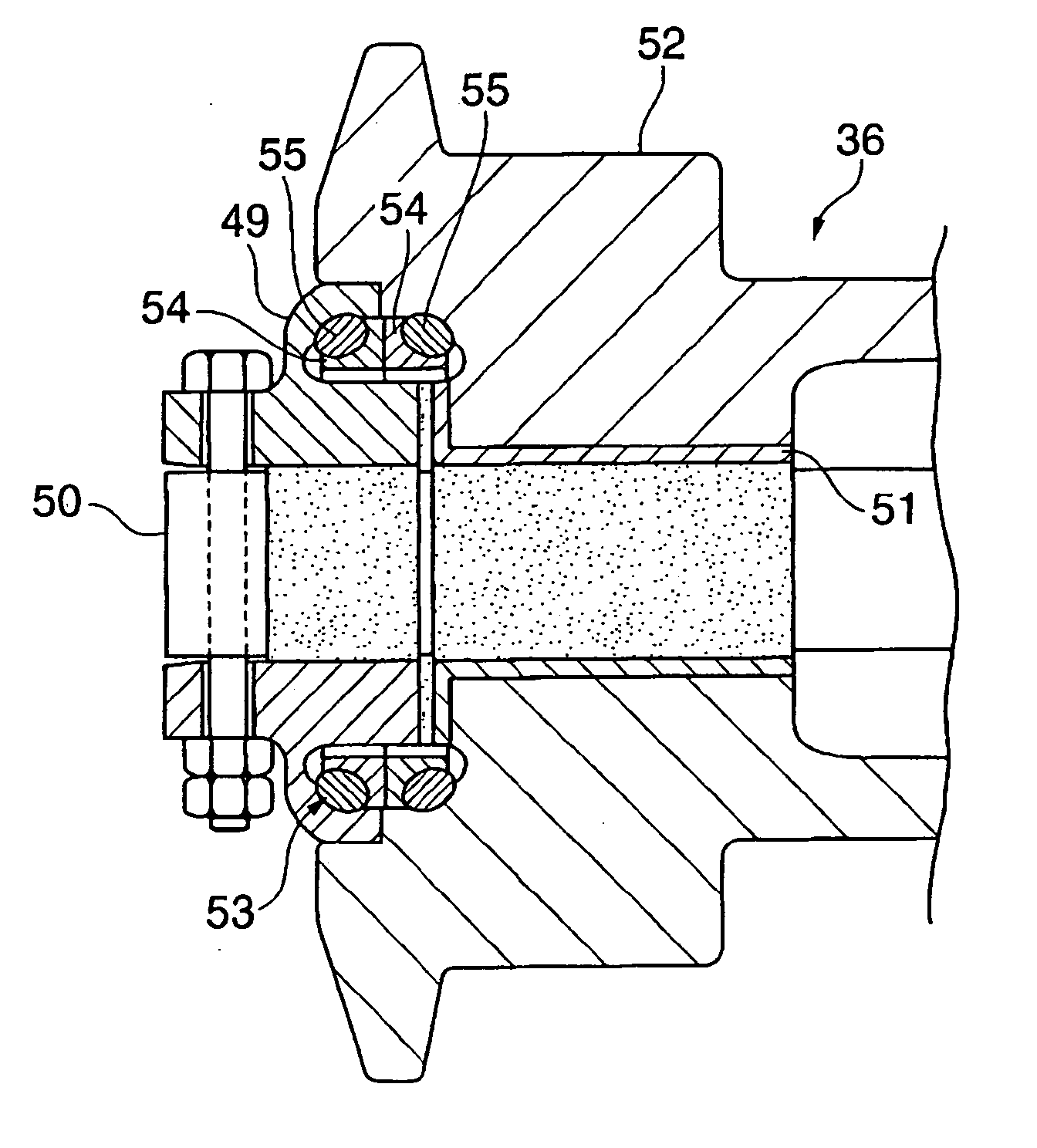

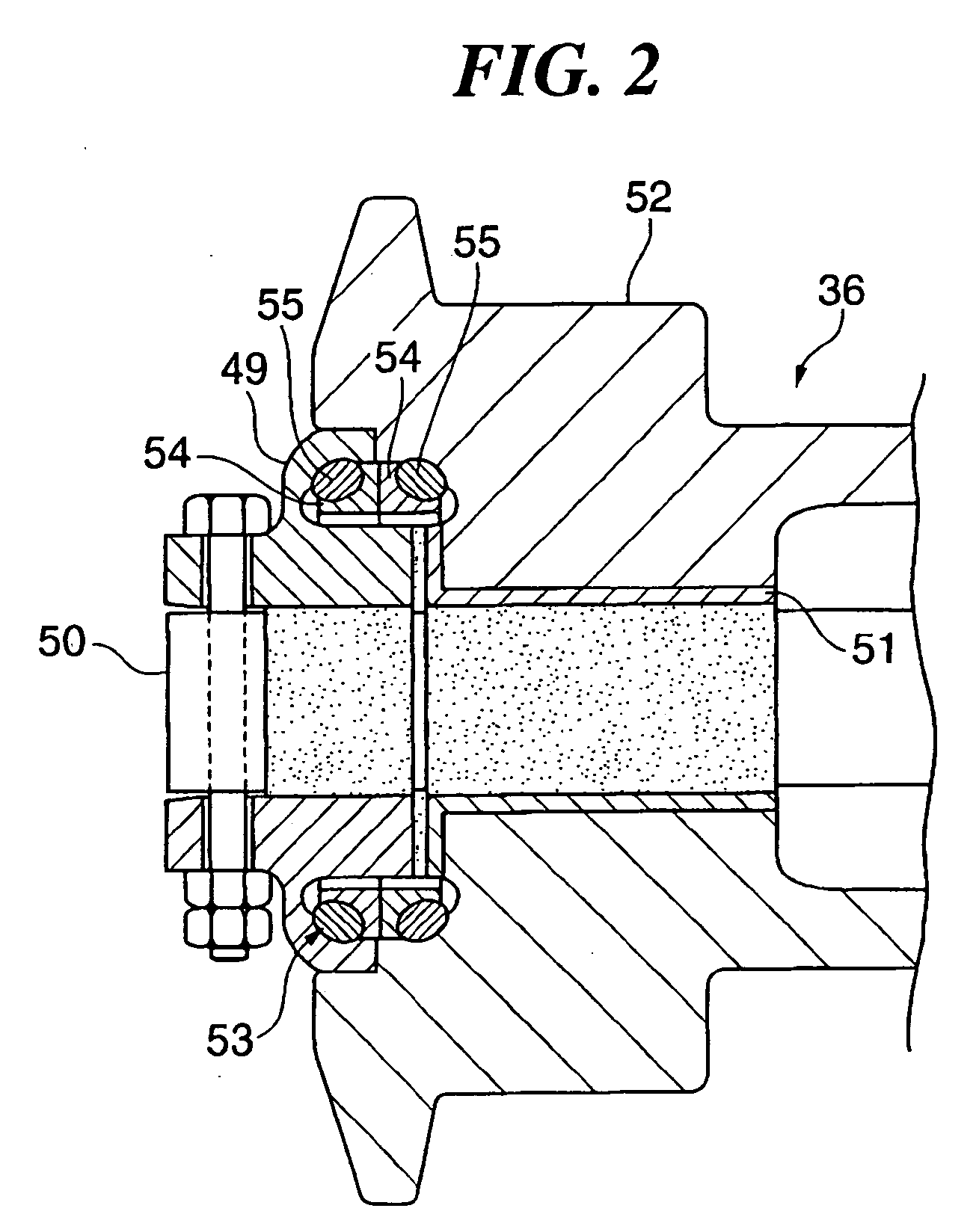

[0087] A cast iron abrasion resistant sliding material will be explained with reference to the accompanying drawings.

[0088] In this example, casting floating seal materials and casting comparative materials shown in Table 1 were used. Each of the material was cast in a shell-shaped mold to prepare comparative fusil specimens. On the other hand, after being cast in a shell-shaped mold, each of materials was re-heated (graphitized) at 950° C. and then quenched to prepare fusil specimens. Then, each of the comparative fusil specimens and the fusil specimens were machined to have a floating seal shape, as shown in FIG. 5, and then lapping treatment was applied to a seal surface (shown in the figure) thereof. Then, seizing resistance of each of the seal surface of both specimens was measured by using a floating seal tester, as shown in FIG. 6.

TABLE 1COMPOSITION (wt %) AND PV VALUE OF MATERIALSAs Cast 950° C.PVPVNo.CSiMnNiCrMoVCoWPAlCuVALUE 1VALUE 2No. 13.791.050.882.050.970.010.031.82...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| Ms temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com