A kind of tungsten steel ceramic hard alloy and preparation method thereof

A technology of ceramic cemented carbide and tungsten steel, applied in the field of cemented carbide, can solve the problems of high equipment and mold requirements, cumbersome degumming process, high degumming waste rate, etc., and achieve excellent thermal deformation resistance, high hardness, and inhibit crystallization The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] The preparation method of Fe-Si-Al oxide nanopowder is as follows:

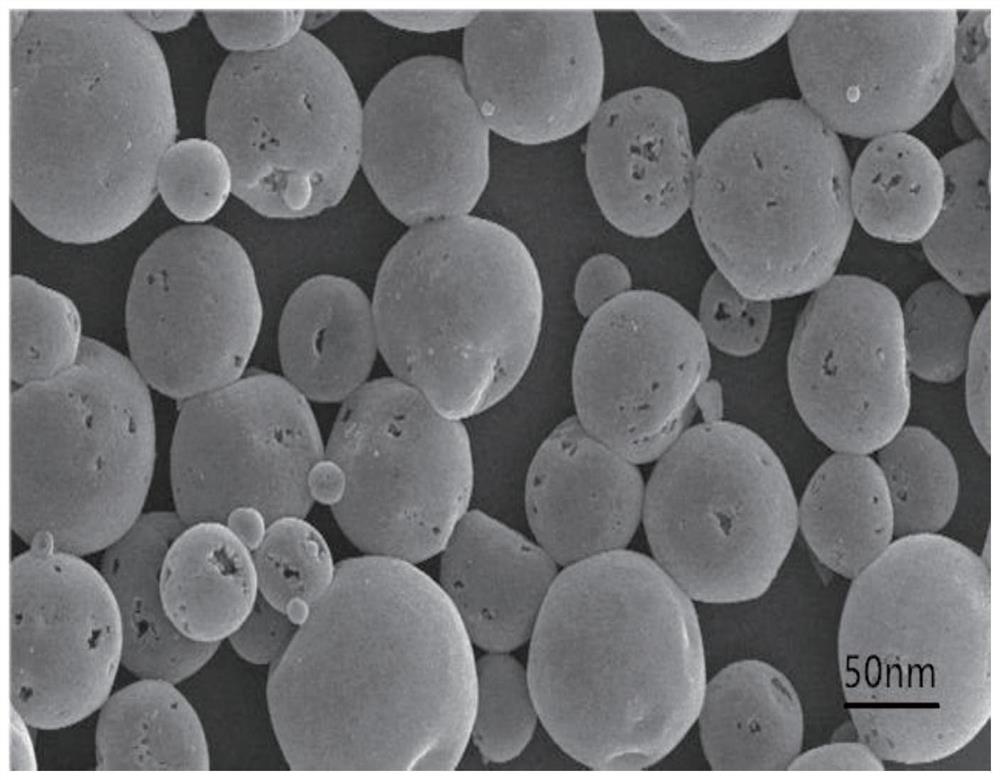

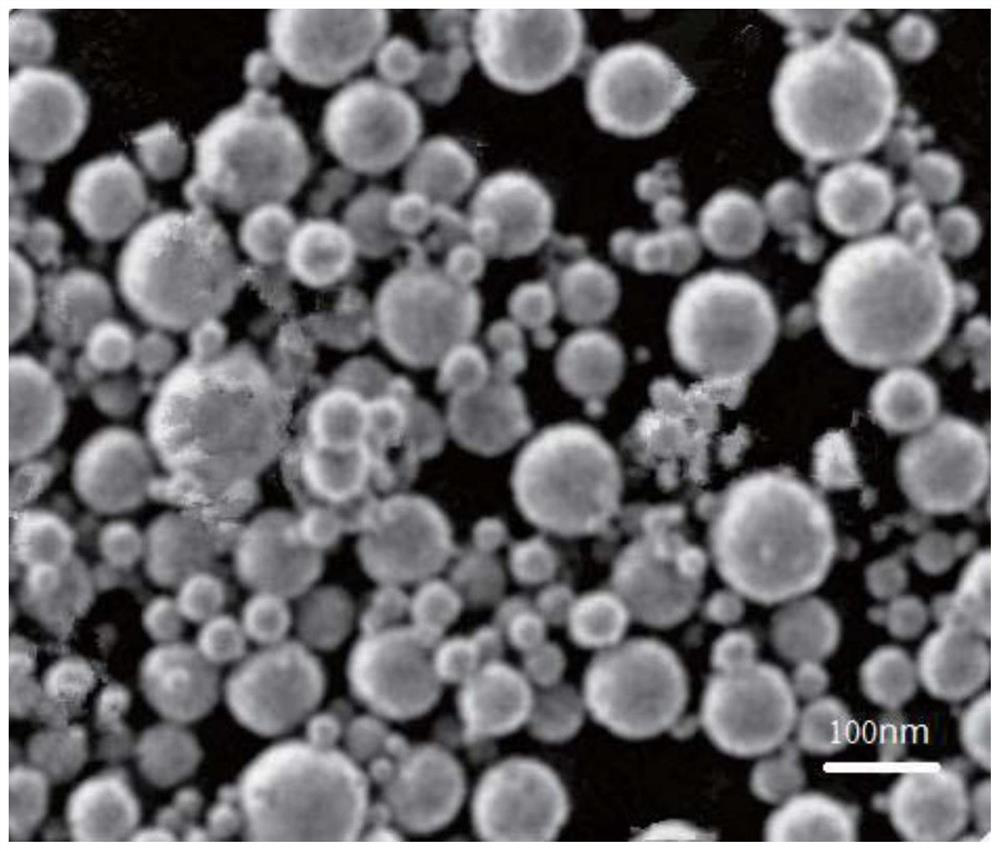

[0054] (1) Porous SiO 2 / Al 2 o 3 Preparation of hollow nanospheres: Dissolve 2g of γ-aminopropyltrimethoxysilane and 10g of aluminum isopropoxide in 50mL of ethyl acetate as the oil phase; prepare oxyethylene-oxypropylene triblock copolymer PEO106-PPO70- The content of PEO106 is 1wt%; the content of sodium dodecylbenzenesulfonate is 2wt% aqueous solution, which is the water phase; add 50mL oil phase to 100mL water phase, emulsify at 10000r / min for 3min, and adjust the pH of the solution to 8. React for 7h, centrifuge at 3000r / min for 15min, wash the solid with deionized water, dry at 70°C for 5h, and calcinate at 400°C for 2h to obtain porous SiO 2 / Al 2 o 3 Hollow nanospheres; figure 1 For the prepared porous SiO 2 / Al 2 o 3 The SEM picture of the hollow nano-microspheres shows that the particle size of the prepared microspheres is within 100nm, and a large number of pores are formed on the ...

preparation example 2

[0057] The preparation method of Fe-Si-Al oxide nanopowder is as follows:

[0058] (1) Porous SiO 2 / Al 2 o 3 Preparation of hollow nanospheres: Dissolve 5g of N-β(aminoethyl)-γ-aminopropylmethyldiethoxysilane and 10g of aluminum isopropoxide in 50mL of ethyl acetate as the oil phase; prepare ethylene oxide The content of -oxypropylene triblock copolymer PEO20-PPO70-PEO20 is 2wt%; the content of sodium hexadecylbenzenesulfonate is 4wt% aqueous solution, which is the water phase; 50mL oil phase is added to 100mL water phase, 15000r Emulsify for 5 minutes at a speed of 1 / min, adjust the pH of the solution to 9, react for 12 hours, centrifuge at 3000r / min for 15 minutes, wash the solid with deionized water, dry at 70°C for 5 hours, and calcinate at 500°C for 4 hours to obtain porous SiO 2 / Al 2 o 3 Hollow nanospheres;

[0059] (2) Preparation of Fe-Si-Al oxide nanopowder: Dissolve 2 g of ferric nitrate in 100 mL of water, add 8 g of citric acid and 5 g of porous SiO prepare...

preparation example 3

[0061] The preparation method of Fe-Si-Al oxide nanopowder is as follows:

[0062] (1) Porous SiO 2 / Al 2 o 3 Preparation of hollow nanospheres: Dissolve 3.5g of N-β(aminoethyl)-γ-aminopropylmethyldimethoxysilane and 10g of aluminum isopropoxide in 50mL of ethyl acetate to form the oil phase; The content of hexaalkyltrimethylammonium bromide is 1.5wt%; the content of sodium octadecylsulfonate is 3wt% aqueous solution, which is the water phase; 50mL of oil phase is added to 100mL of water phase, under the speed of 12500r / min Emulsify for 4 minutes, adjust the pH value of the solution to 8.5, react for 10 hours, centrifuge at 3000r / min for 15 minutes, wash the solid with deionized water, dry at 70°C for 5 hours, and calcinate at 450°C for 3 hours to obtain porous SiO 2 / Al 2 o 3 Hollow nanospheres;

[0063] (2) Preparation of Fe-Si-Al oxide nanopowder: Dissolve 2 g of ferric nitrate in 100 mL of water, add 6 g of citric acid and 4 g of porous SiO prepared in step (1) 2 / A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com