Film adhesion device and film adhesion method

a film adhesion and film technology, applied in mechanical control devices, paper/cardboard containers, instruments, etc., can solve the problems of poor yield, high risk of pin holes and so on, and high film thickness, so as to minimize the effect of the lower layer portion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example

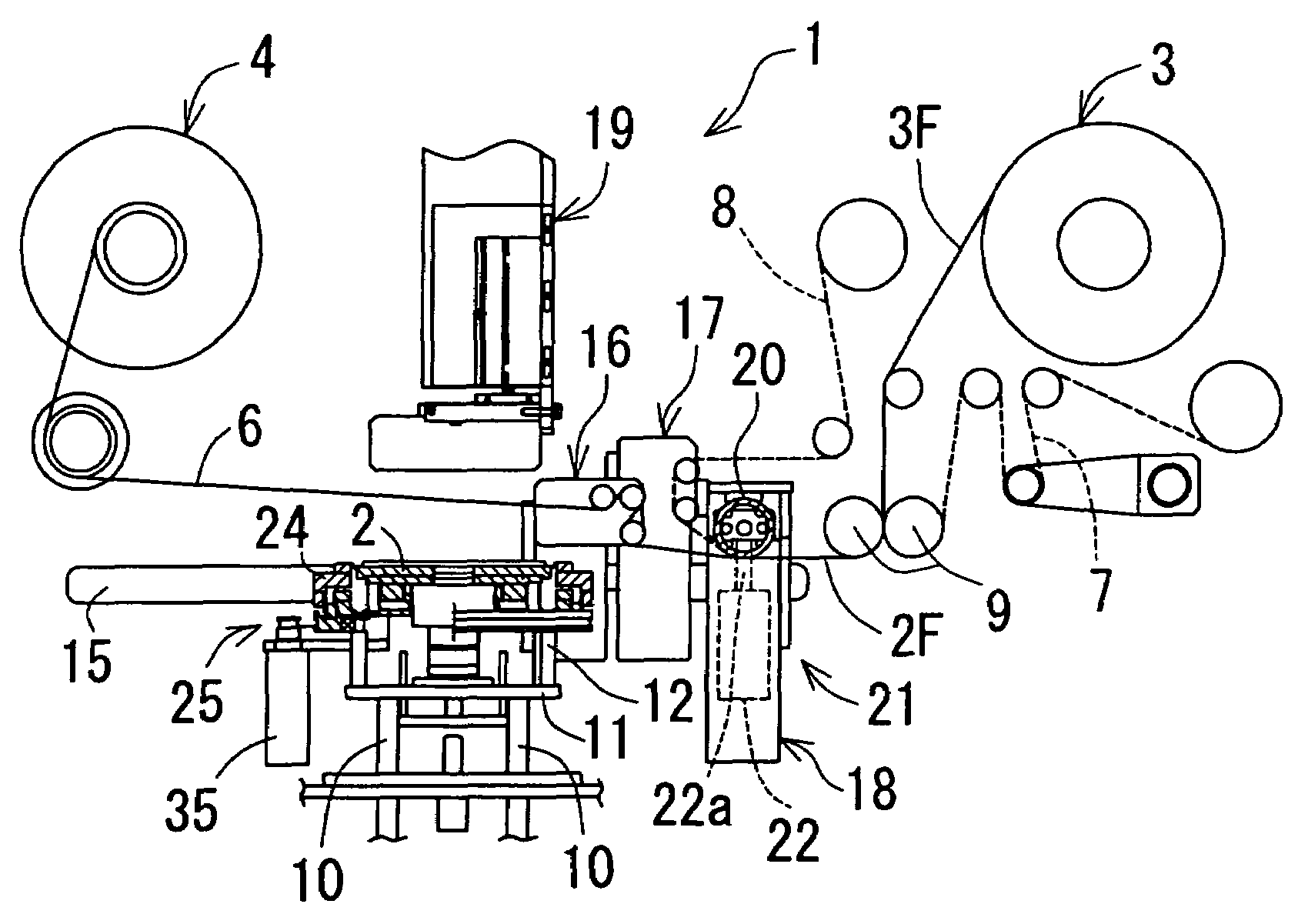

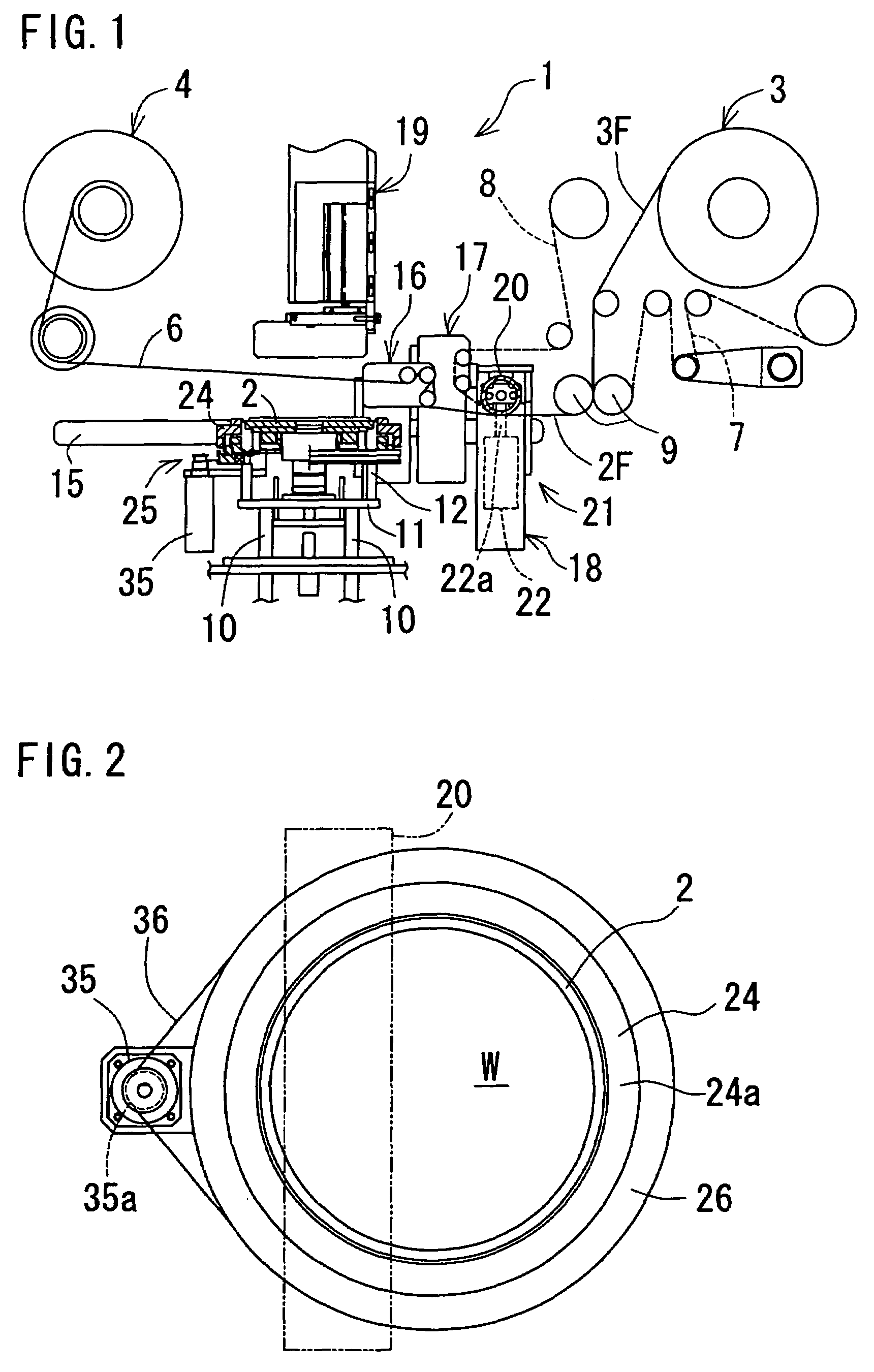

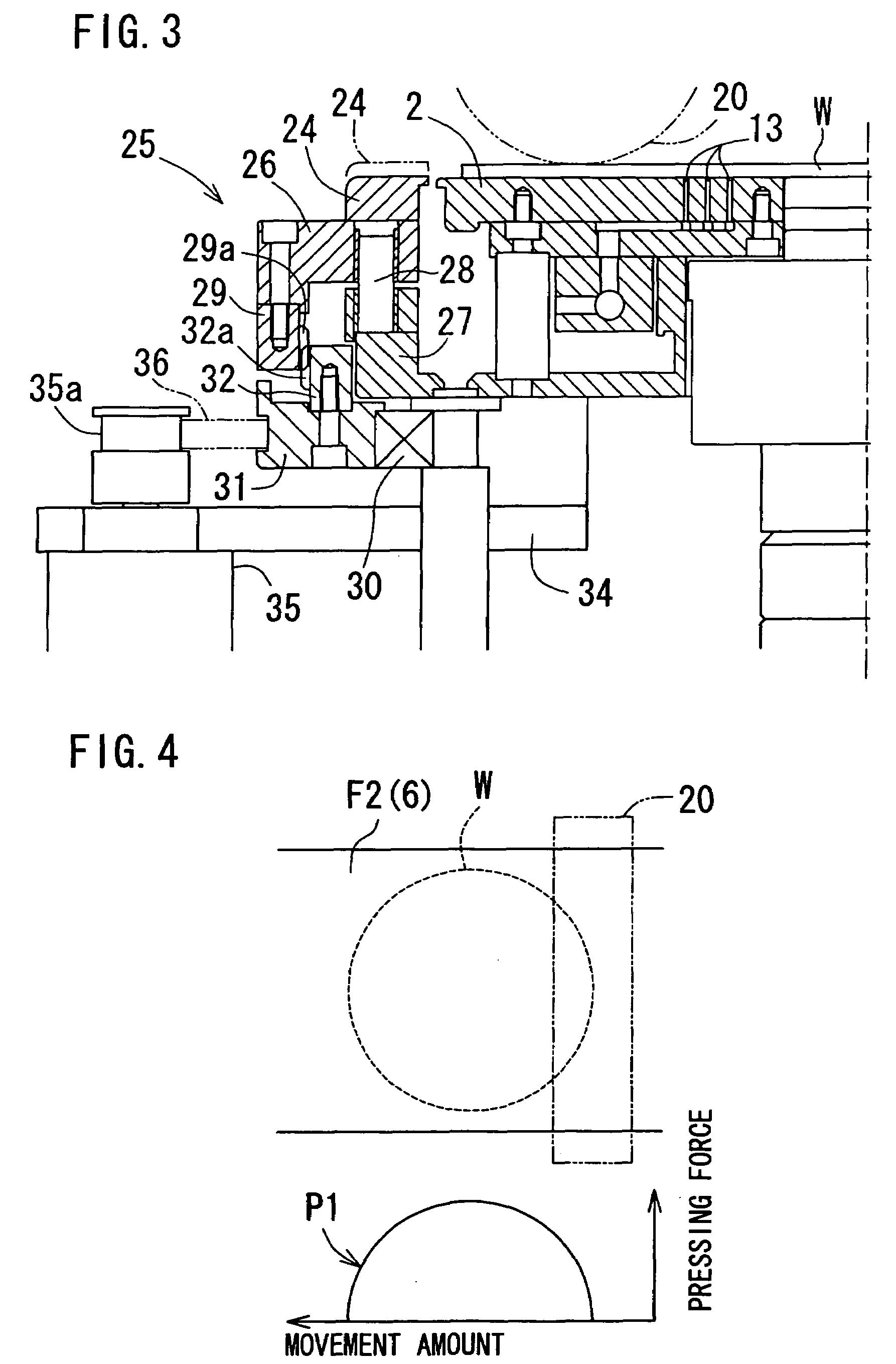

[0079]A working example of the present invention will now be described with reference to the drawings.

(1) Structure of Film Adhesion Device

[0080]As shown in FIGS. 1 and 2, a film adhesion device 1 according to this working example includes a disc-shaped table 2 carrying a circular plane-form semiconductor wafer W. A film supply portion 3 and a winding portion 4 forming a pair are disposed at a predetermined interval diagonally above the table 2. A three-layer film F3 is supplied from the film supply portion 3. The three-layer film F3 is constituted by a photoresist film 6 having a heat-sensitive adhesive property with a carrier film 7 laminated onto one surface thereof and a reinforcing film 8 laminated onto the other surface thereof. The carrier film 7 is peeled away from the three-layer film F3 by a pinch roller 9 such that the three-layer film F3 becomes a two-layer film F2. The two-layer film F2 is pressed onto, and thereby adhered to, the surface of the semiconductor wafer W, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap