Functional fluids having low brookfield viscosity using high viscosity-index base stocks, base oils and lubricant compositions, and methods for their production and use

a technology of low viscosity and functional fluids, applied in the field of low viscosity base stocks and base oils, can solve the problems of most complex and costly sub-assemblies, and achieve significant low-temperature performance benefits and improve the performance of finished functional fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

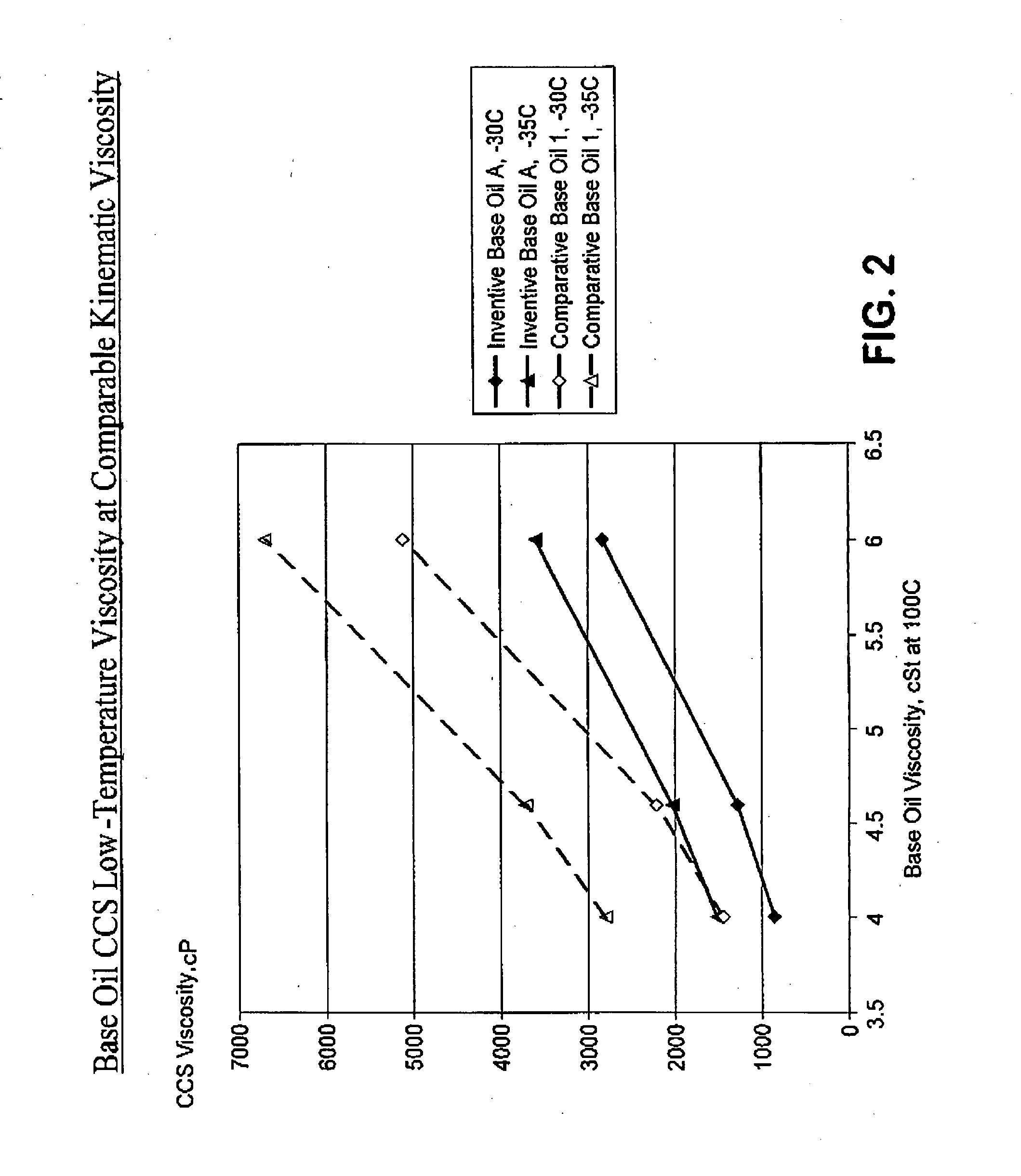

[0186] By controlling other non-inventive process parameters well known to those skilled in the art, the base stocks incorporated into the functional fluids of this inventions as described herein can be made over a range of low to high viscosity oils as is typical in the industry thus allowing for blending of base stocks with a final viscosity between those two end points. In this first example, the base stocks were manufactured using the inventive method to a higher viscosity level of 6.6 cSt and a lower viscosity level of 4.0 cSt. As may be seen in table 3, the Inventive Oil A (isomerized slack wax) was then blended to two viscometric targets: 4.0 cSt and 5.7 cSt. Similarly, the Inventive Oil B for this example was made from a Fischer-Tropsch wax, blended to final viscosity targets of 4.0 cSt and 6.3 cSt. The Comparitive Base Oils for example 1 are commercially available base stocks blended to viscometric targets of 4 cSt, 5 cSt and 8 cSt.

[0187] Viscometric properties of Inventiv...

example 2

[0189] For example 2, five blended functional fluids were created. Blend 1, the comparative example, is a functional fluid made from a commercially available Group II base stock with the same target viscosity level as the inventive examples (see table 4). Blends 2 and 3 and Blends 6 and 7 are functional fluids incorporating Inventive Base Stock A from Example 1, specifically the 4 cSt viscosity target specification. Blends 4 and 5 are functional fluids incorporating Inventive Base Stock B from Example 1, specifically the 4 cSt viscosity target.

[0190] The properties of Comparative Blend 1 and Inventive Blends 2-7 at comparable viscosity indices are shown below in Table 4. The Kinematic Viscosities were measured by ASTM method D445. Brookfield viscosities were measured by ASTM method D2983. Pour point was measured by ASTM D5950. Blend 1 is the average results of Blends 1A and 1B seen in Table 5.

TABLE 4Blend 1Blend 2Blend 3Blend 4Blend 5Blend 6Blend 7Component, vol %Comparative base...

example 3

[0192] In an effort to recreate the results of the current invention which uses the catalytic dewaxing, by employing standard solvent dewaxing base oil extraction techniques, a third experiment was performed. The commercially available Group II base stock of Example 2 was subjected to 18 modifications commonly used to improve the low temperature properties of the base stock. These modifications were incorporated into functional fluids and the Brookfield Viscosity of each functional fluid was measured. The results are compared to the Brookfield viscosities of the Inventive functional fluids from Example 2 (Blends 2-5) in Table 5.

TABLE 5Base StockBlendPourATF Brookfield cPATF Brookfield cP#Point ° C.(Comparative Base Oils)(Inventive Base Oils)1A−2019,0261B−2019,5301-1−2018,8691-2−2315,9501-3−2117,2691-4−1824,3951-5−1526,8691-6−1922,3451-7−1426,6691-8−2019,2261-9−2316,2071-10−2118,9061-11−2216,0971-12−2023,3951-13−2417,2461-14−2617,8961-15−1917,5961-16−2017,4961-17−2017,9461-18−2315,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com