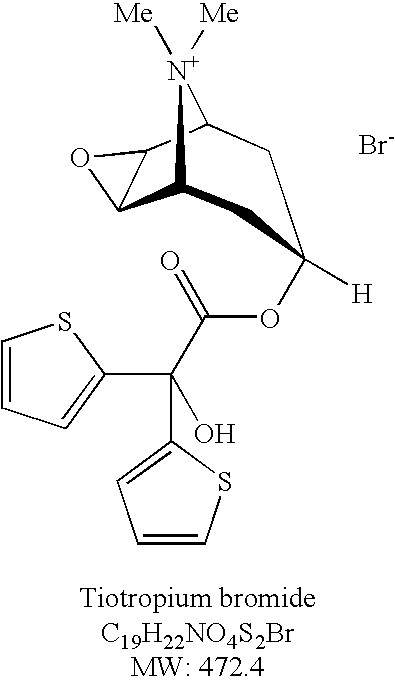

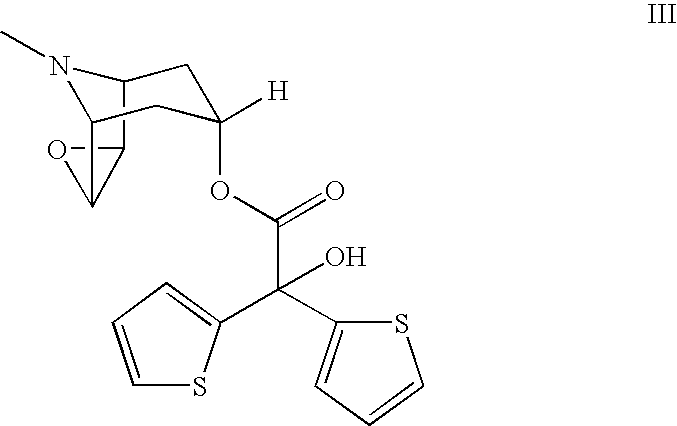

Process for the preparation of tiotropium bromide

a technology of tiotropium bromide and process, applied in the field of improvement, can solve the problems of more complex synthesis methods and unsuitable methods for industrial scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

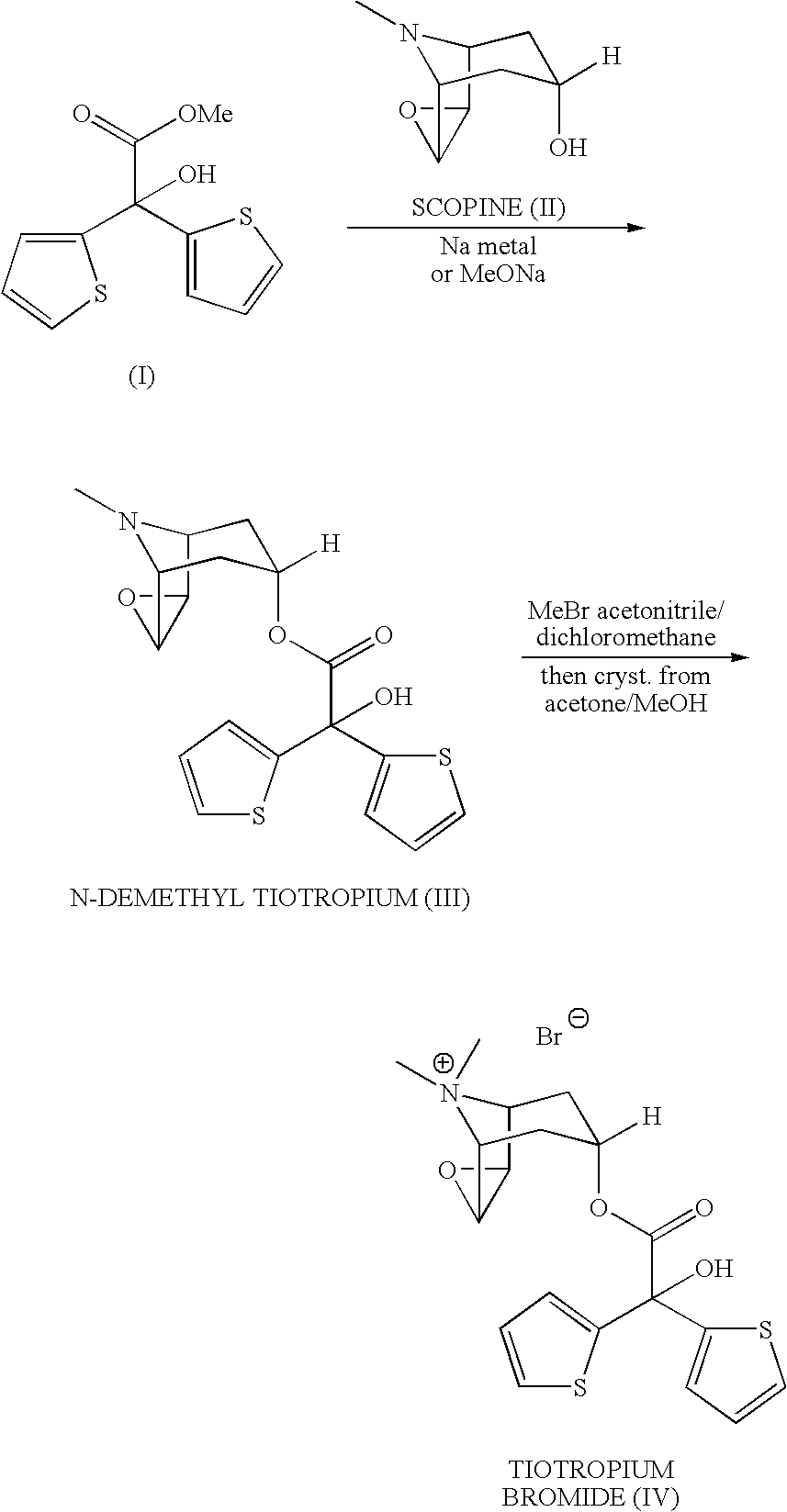

Method used

Image

Examples

example 1

Comparative Example: Preparation of Scopine Hydrochloride According to GB '781

[0063] 10.0 g (22.84 mmol) of scopolamine hydrobromide trihydrate was suspended in 100 mL of absolute ethanol, and cooled to about 0° C. Sodium borohydride (4.0 g, 105.7 mmol) was then added portion-wise while maintaining the temperature at a maximum of 30° C. 4.8 mL of water was then added to the reaction mixture. After 3.5 hours, the reaction was completed and 50 mL of diethyl ether was then added. The reaction was then cooled to 0° C., and acidified with 2M hydrochloric acid in diethyl ether to a pH of about 2. The suspension was stirred at room temperature for 30 minutes and then filtered on GochP3. The white solid was dried at 45° C. under vacuum for 4 hours, yielding 9 g of product containing 79% of salts determined by sulphuric ashes.

example 2

Preparation of Methyl di-(2-thienyl)glycolate

[0064] 1050 mL of tetrahydrofuran was loaded in a 2 L round bottomed flask. 22.6 g (0.93 mol) of magnesium turnings were then added, and the mixture was kept at 35° C., while catalytic bromoethane (200 mg, 1.84 mmol) was loaded. 150 g (0.92 mol) of 2-bromothiophene was added dropwise, and after about 15% (13 ml) of reagent was exothermicity was observed. The temperature was maintained at a maximum of 50-55° C., and the remaining 2-bromothiophene was then added. At the end of the addition, the reaction mixture was heated to 65° C. for 1.5 hours to 2 hours, and then cooled to 25° C.

[0065] The Grignard solution thus formed was added drop-wise, in about 2.5 hours to 3 hours, into a solution of dimethyl oxalate (54.3 g, 0.46 mol) dissolved in 300 mL of tetrahydrofuran, while maintaining the temperature at maximum 5-10° C. via cooling bath.

[0066] The solution was kept under stirring for 0.5 hours to 1.0 hours at 5-10° C., and then saturated ...

example 3

Crystallization of Methyl di-(2-thienyl)glycolate in Ethanol 96% / n-heptane

[0072] Crude methyl di-(2-thienyl)glycolate (2.0 g) was dissolved in ethanol 96% (8.0 ml) at 45° C. 16.0 mL of n-heptane were then added drop-wise at 45° C. in 20 minutes. The solution was maintained at 45° C. for hour, and then it was cooled to 0° C. in 1 hour, and left at this temperature for another hour. The solid was filtered on a sintered glass funnel and it was washed once with n-heptane (2 mL). Drying for 6 hours at 50° C. under vacuum yielded 1.4 g of methyl di-(2-thienyl)glycolate (70%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com