Firearm Grip with Rest

a technology for firearms and grips, applied in the field of firearm grips, can solve the problems of increasing shooting difficulty, structural damage in the long term, and still being rather inconvenient and laborious, and achieve the effects of preventing frostbite, poor heat conductivity, and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

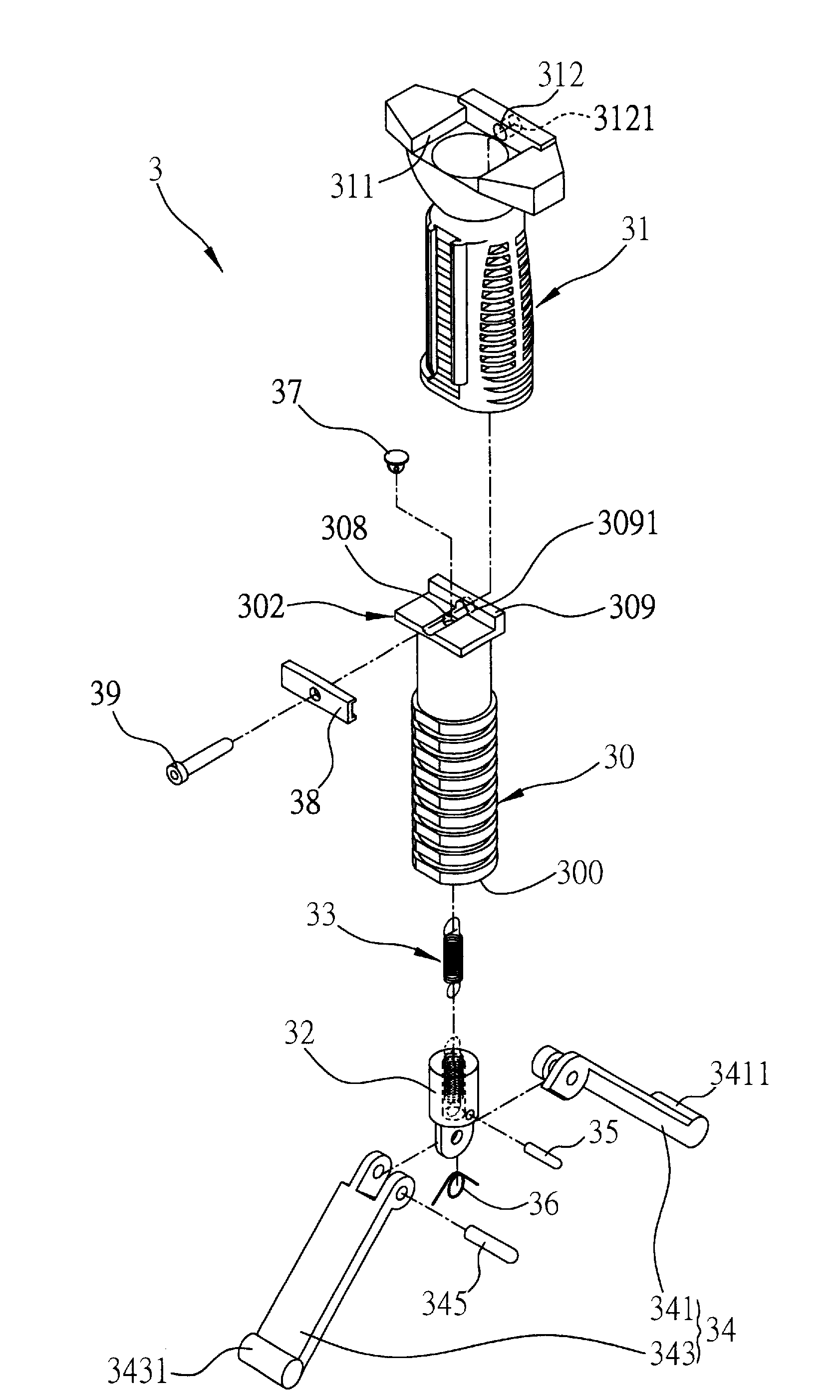

[0044]Referring to FIG. 3A, a schematic diagram of a firearm grip with a rest according to a first embodiment of the present invention is shown. The firearm grip 3 of the present invention comprises: a grip body 30 having a hollow portion; a shell 31 for enclosing and combined with an outside of the grip body 30 and exposing a bottom 300 of the grip body 30; a rest received in the grip body 30 and capable of being projected from the bottom 300 of the grip body 30 to position the firearm grip 3 on a setting surface (not shown); and an elastic member 33 for connecting the grip body 300 and the rest and for providing elasticity to retract the rest into the grip body 30.

[0045]The material of the grip body 30 is aluminum alloy. The shell 31 is a rubber, plastic or heat-insulating shell to insulate the grip body 30 again heat conducted from the barrel during shooting. Additionally, the shell 31 can be formed as an ergonomic shape that facilitates gripping of the shell 31 by a user.

[0046]A...

second embodiment

[0054]Referring to FIGS. 4A to 4C, a firearm grip with a rest according to a second embodiment of the present invention is shown.

[0055]As shown in FIG. 4A, the second embodiment is similar to the first embodiment, with differences in that in the second embodiment, the rest is a column 41 with a combining portion 411 formed on a top surface thereof, such that the rest is coupled to an end of the elastic member 43 via the combining portion 411, wherein the combining portion 411 may for example be hollow and is coupled to the end of the elastic member 43 by a laterally disposed rod 42.

[0056]Additionally, a protrusion 412 can be provided at the bottom of the column 41, for being inserted in soft ground. The protrusion 412 may also function as a pivot point when adjusting the shooting direction of the barrel. A protruding step 413 can also be formed on the bottom of the column 41 so as to be blocked at the bottom 400 of the grip body 40 when the column 41 is received in the grip body 40,...

third embodiment

[0059]Referring to FIG. 5A, a firearm grip with a rest according to a third embodiment of the present invention is shown.

[0060]The third embodiment is a modification of the second embodiment, with differences in that in the third embodiment, the rest is a column 53, the top of which is coupled to an end of the elastic member 54. More specifically, a dent 530 is formed on the top of the column 53 such that a rod 52 can be laterally disposed in the dent 530 to couple the column 53 to the end of the elastic member 54.

[0061]An elastic operating member 51 is provided on the bottom of the grip body 50. The elastic operating member 51 comprises a first engaging part 510 extended into the grip body 50, and a second engaging part 531 is provided on a side of the column 53 and corresponds to the first engaging part 510. The column 53 can be received in or projected from the grip body 50 according to an engagement between the first engaging part 510 and the second engaging part 531. The engage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com