Bearing monitoring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

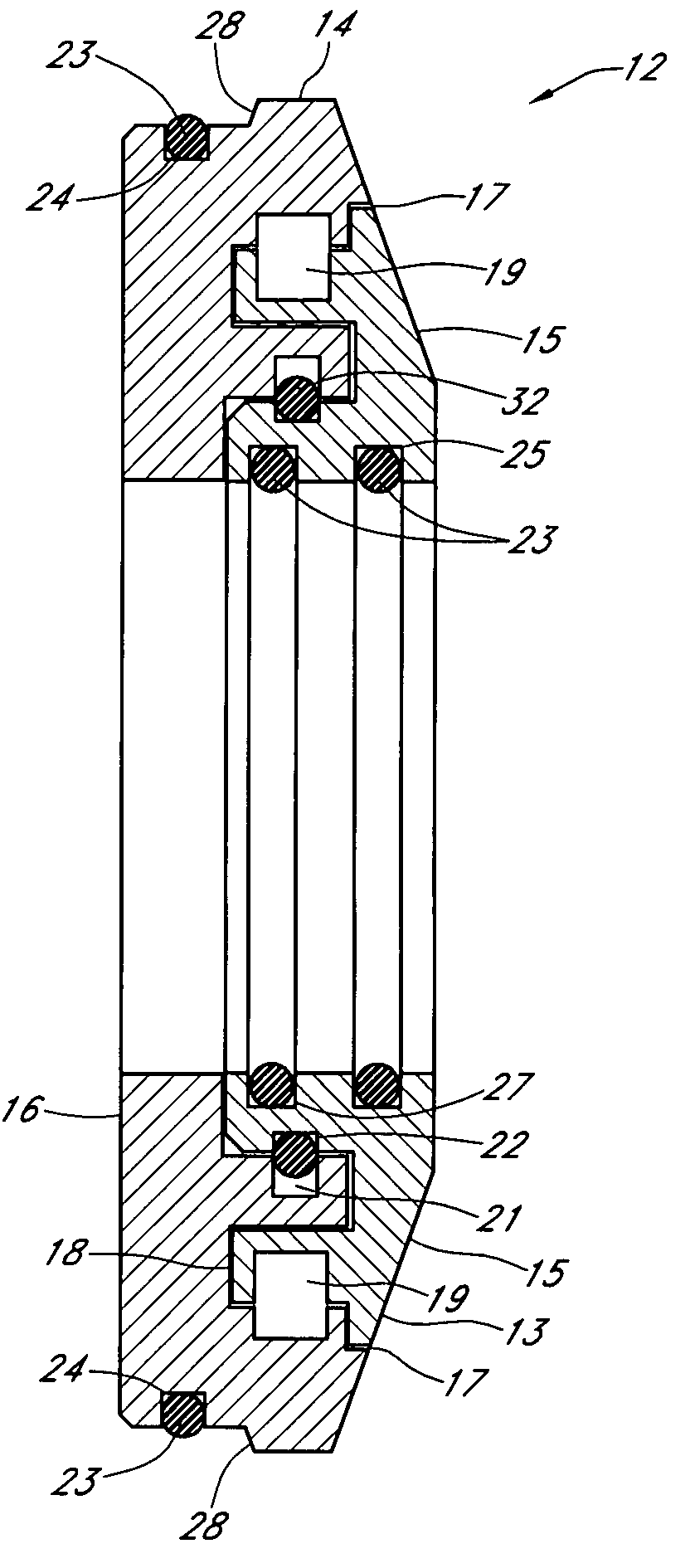

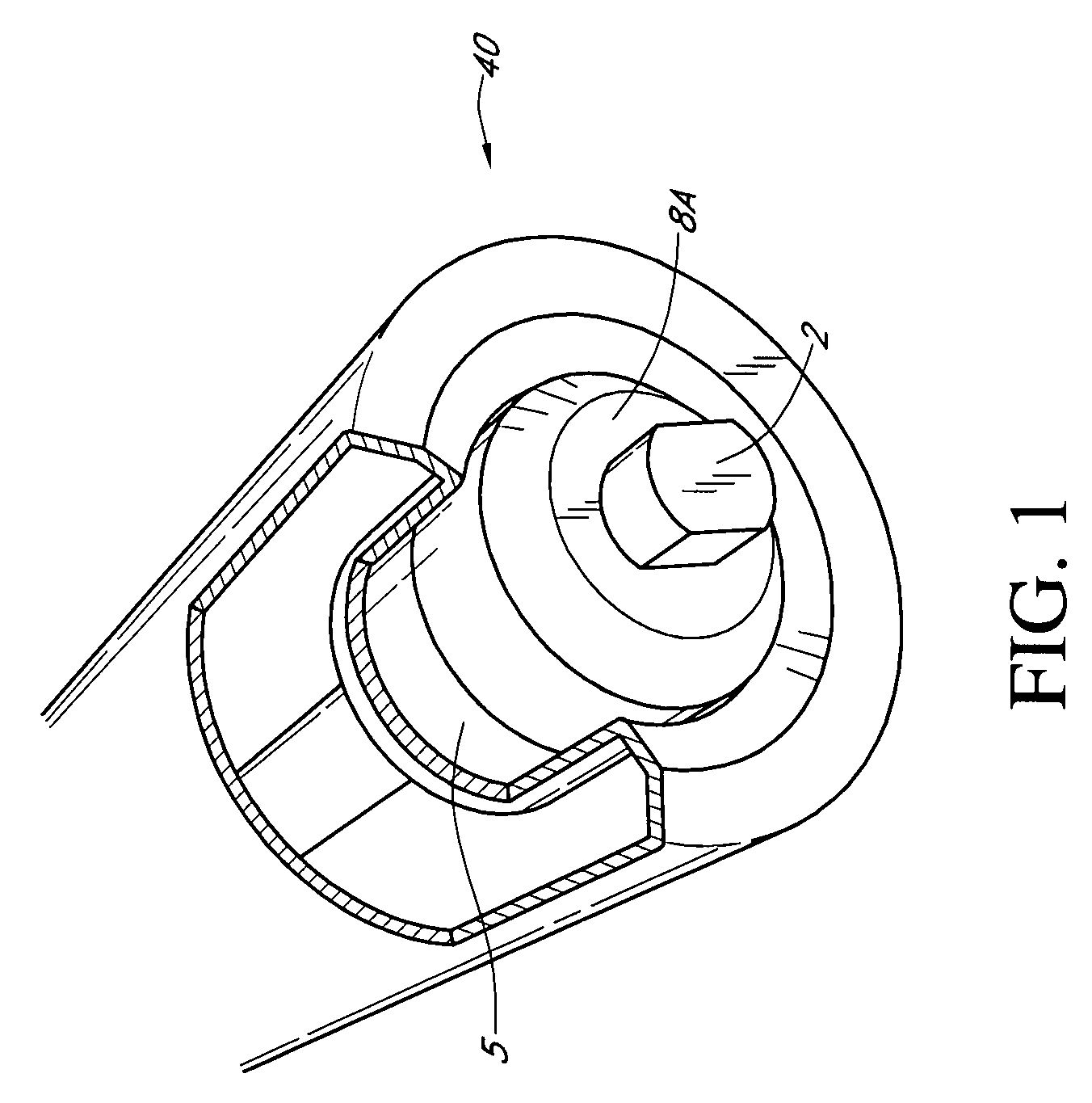

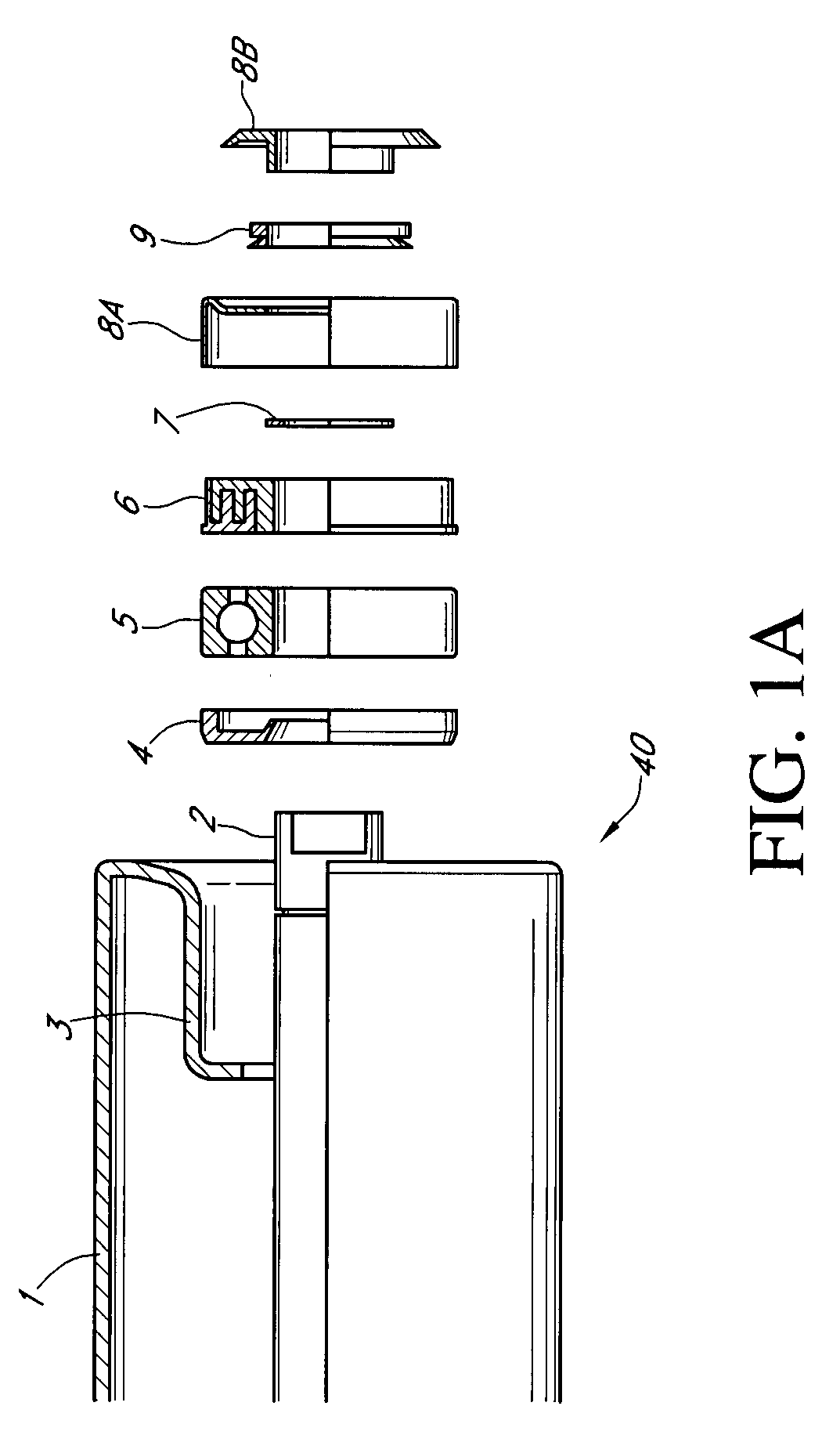

[0048]FIGS. 1 and 1A illustrate the prior art as taught by U.S. Pat. No. 6,802,410 issued to Dyson et al. for “Conveyor Roller Bearing Housing,” which is incorporated by reference herein.

[0049]There are two principal sections shown in FIGS. 1 and 1A of the prior art bearing assembly; one external and one internal. The external section is comprised of a cover 8A and stone guard 8B. As taught by the prior art, the design of the cover 8A and stone guard 8B and the shape of the bearing housing 3, are intended to be self-cleaning when rotating (i.e., centrifugally expel all pollutants). Applicant has not found this to be the case.

[0050]As illustrated in FIGS. 1 and 1A, the internal section is typically comprised of a triple lip labyrinth seal 6 (sometimes referred to as a lip ring), often made of nylon PA6, which is greased to give further primary bearing 5 protection. In other applications, the labyrinth seal 6 is made from soft, anti-abrasive rubber with a large contact surface that pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com