Method and apparatus for controlling FCC hydrotreating by near-infrared spectroscopy

a technology of near-infrared spectroscopy and hydrotreating method, which is applied in the direction of cracking process, catalytic cracking, petroleum industry, etc., can solve the problem that current analytical techniques require a long lead time to generate the needed input to the model, and achieve improved yield selectivity, improved control and operation of targets, and higher product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0038]Different feedstocks will result in different yields from the FCC process. If the unit is operating against a constraint, the process will need to adjust to avoid exceeding an equipment limitation. Typical process variables include feed rate, reactor temperature, feed preheat and pressure. The process response from each of the variables is non-linear. The optimum set of conditions to maximize profitability to unit constraints will typically vary depending upon the feed quality. The following is an example of different operating conditions required to maximize profitability for a change in feed:

Nor-New FeedNew FeedNew Feedmalwith Multi-with Onlywith OnlyOper-variableRateROTationOptimizationVariedVariedFeed PropertiesAPI24.621.821.821.8UOP K11.6911.7711.7711.77Concarbon (%)0.150.590.590.59Nitrogen (ppm)1150162162162Sulfur (%)0.340.550.550.551-ring Aromatics (%)352929292-ring Aromatics (%)342626263-ring Aromatics (%)172525254-ring Aromatics+(%)14202020Process ConditionsFeed Rate ...

example 2

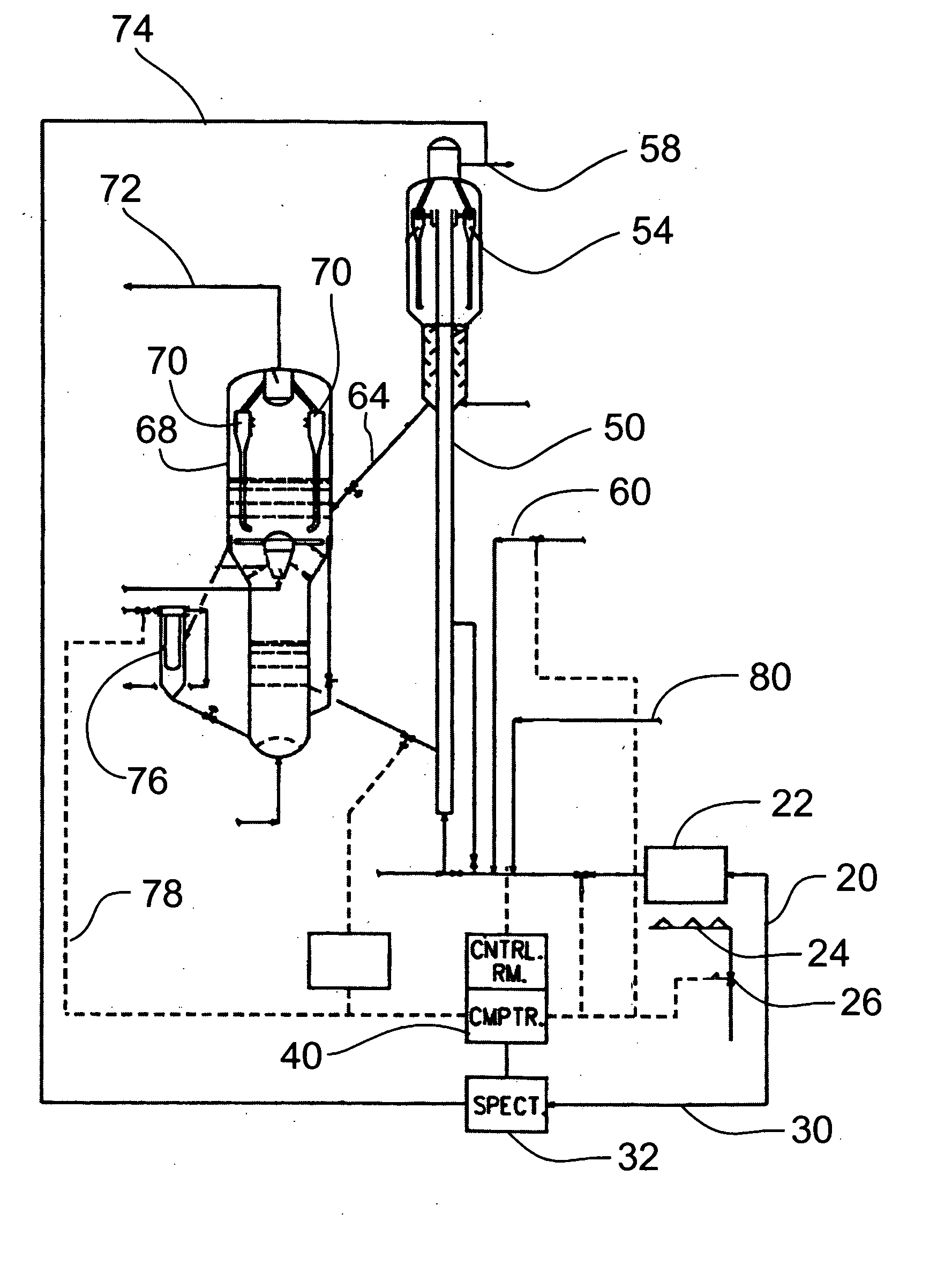

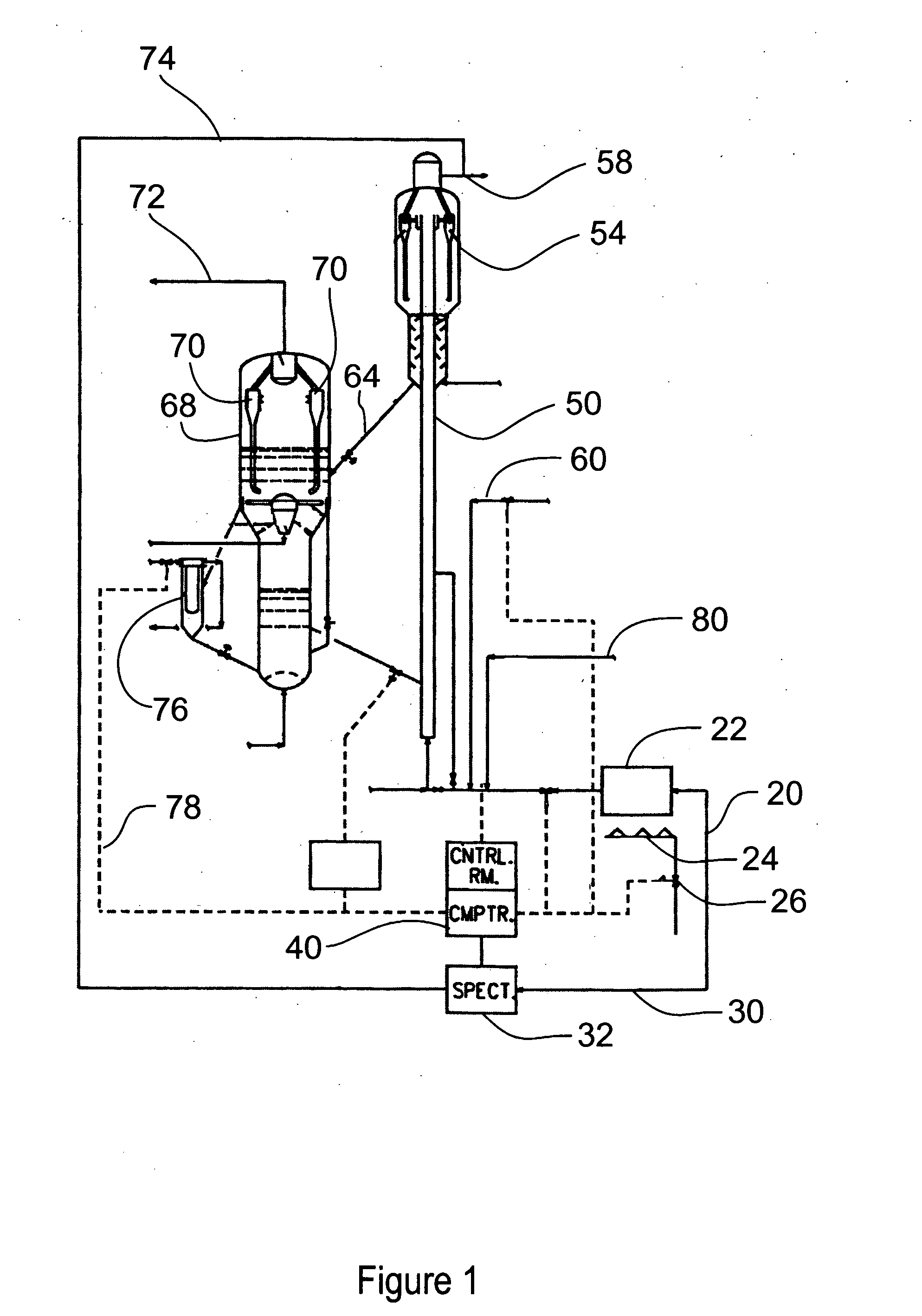

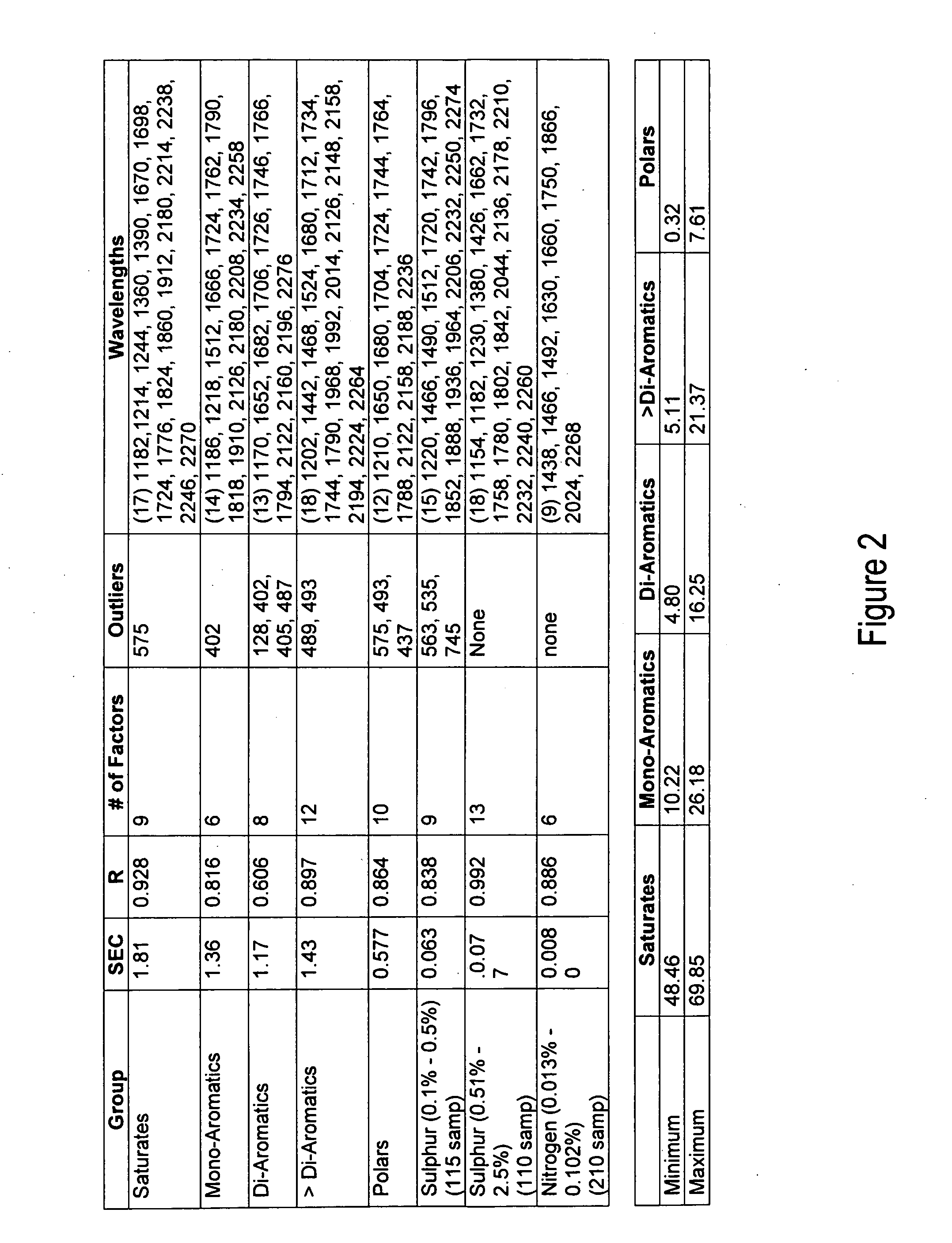

[0040]FIG. 2 is a Table which shows samples, including hydrotreater chargers and products and FCC feeds used to control weight percents of each hydrocarbon class.

[0041]Two hundred fifty samples, including hydrotreater charges and products and FCC feeds were used to create a PLS model for predicting weight percents of each hydrocarbon class. The samples were analyzed using the online NIR. Wavelengths were chosen for each group and a summary appears in FIG. 2.

example 3

[0042]FIG. 3 is a plot that illustrates HDS vs. AS mode differences. The plot shows FCC feed sulfur under different operating philosophies. The feed sulfur is held constant and aromatics, nitrogen or concarbon parameters are varied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com