Standalone thermal energy recycling device for engine after-treatment systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

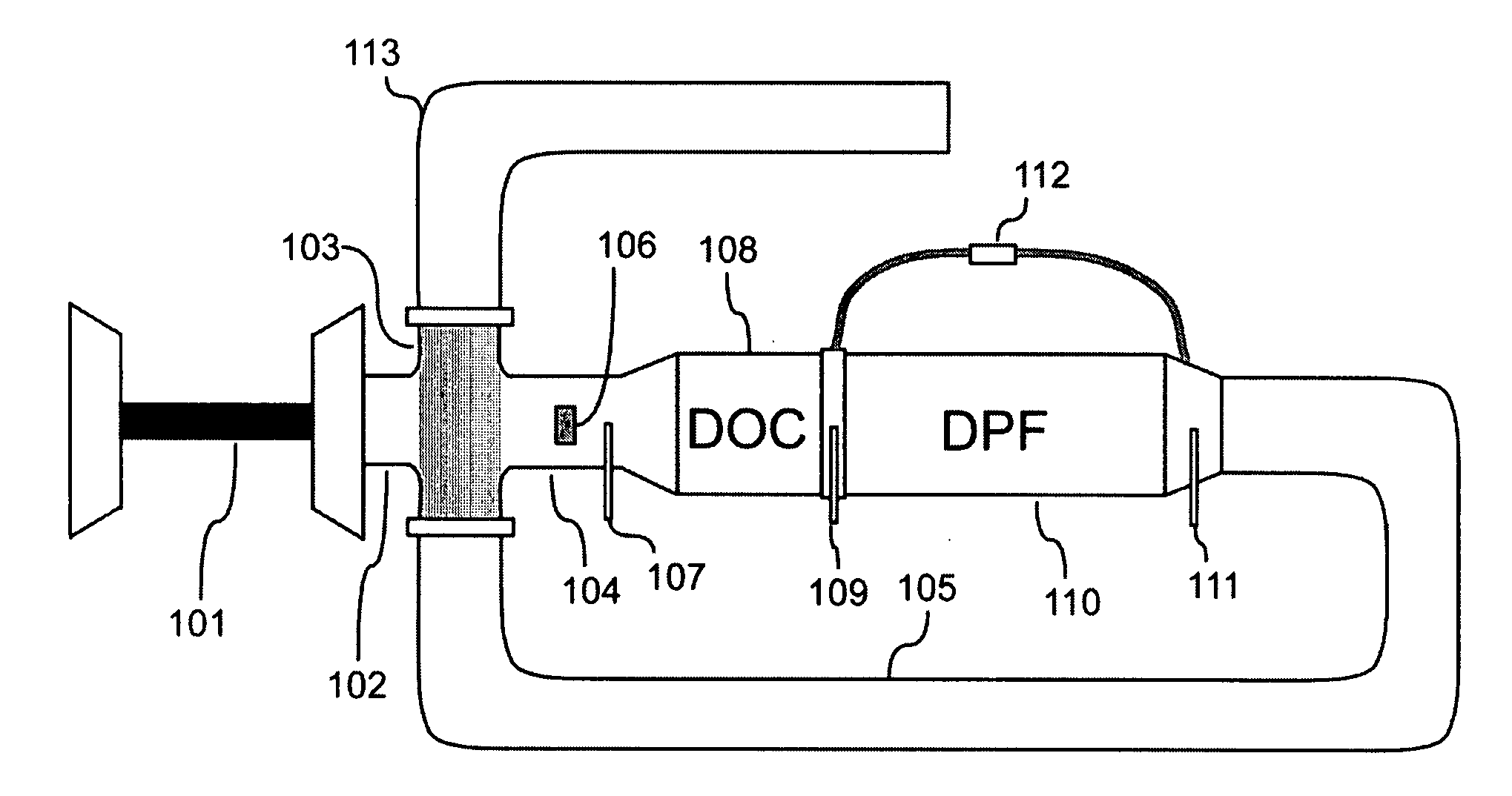

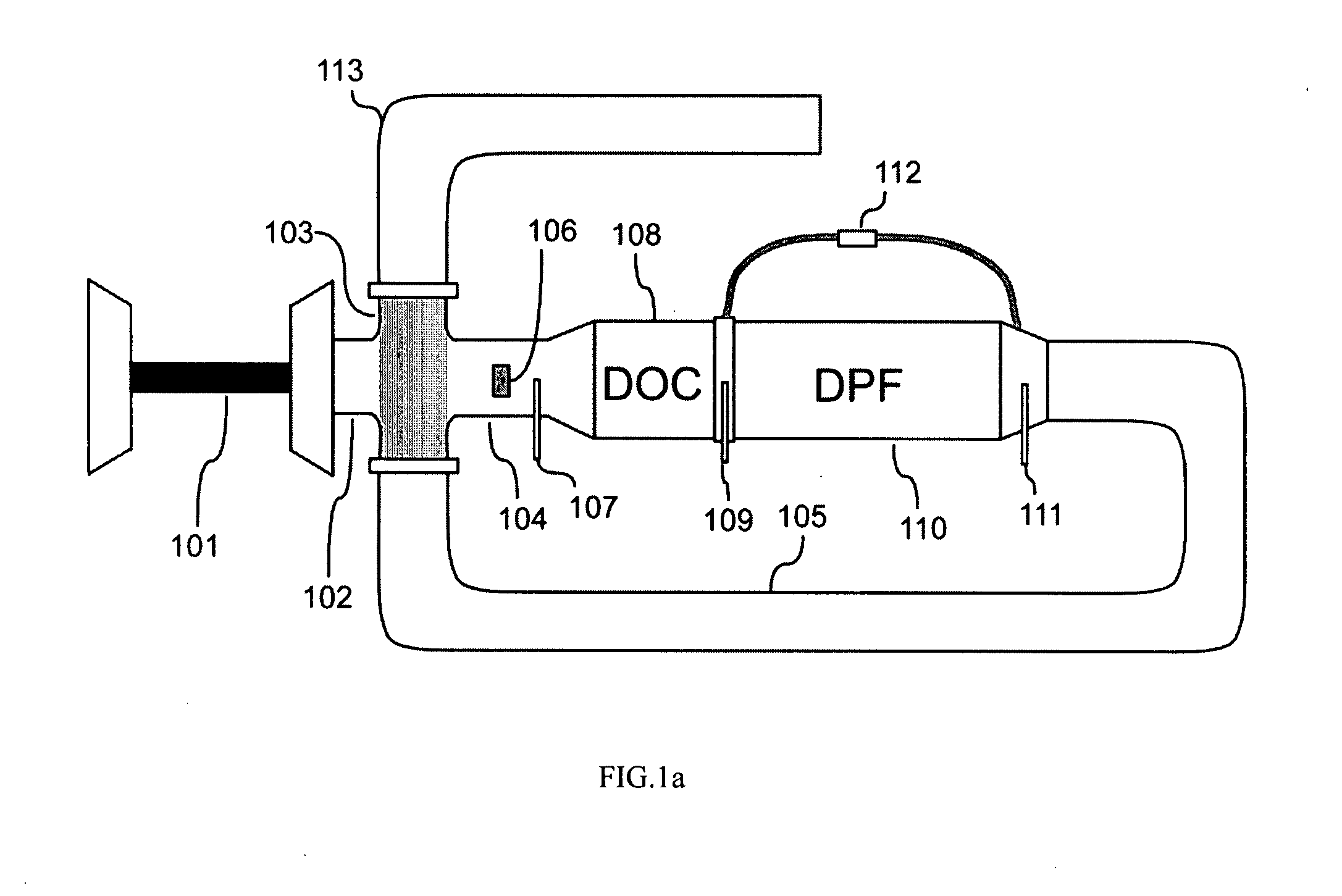

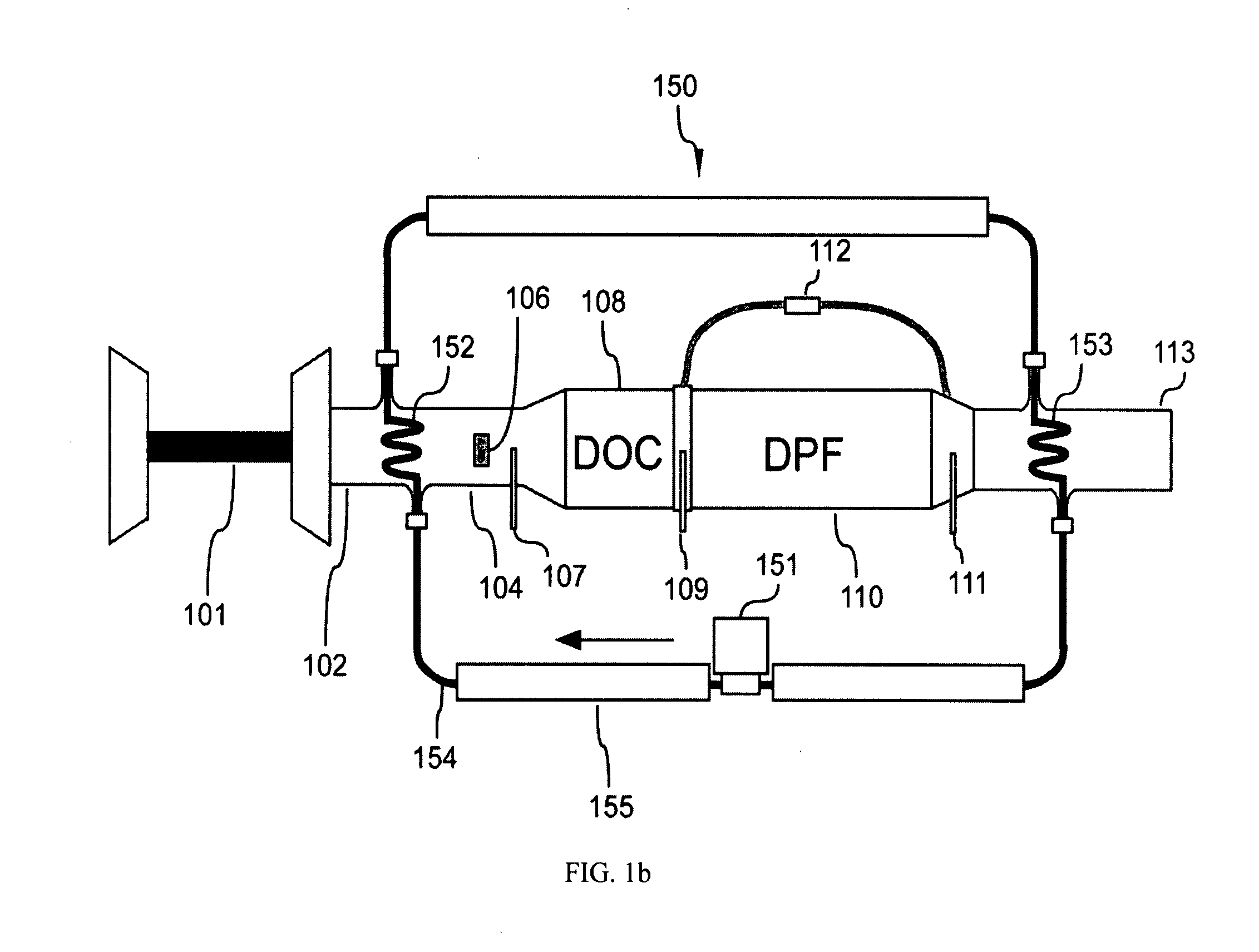

[0036]As depicted in FIG. 1, in an after-treatment system, a standalone heat exchange device 103 is connected with a turbocharger 101 through a pipe 102. Another pipe 104 is used to connect the heat exchange device 103 to a DOC 108, in which the HC, CO, and NOx are oxidized. Particulate matter (PM) generated by the engine is trapped in a DPF 110. A pipe 105 connects the DPF 110 back to the heat exchange device 103, and a pipe 113 conducts exhaust air off the after-treatment system.

[0037]When certain amount of PM deposits in the DPF 110, a regeneration process is triggered, and HC injected from a doser 106 is oxidized in the DOC 108 to provide heat for burning off PM in the DPF 110. During the regeneration process, the DOC inlet temperature is measured by a thermistor 107, while the DOC outlet temperature is monitored by using a thermistor 109. To effectively monitor the DOC conversion efficiency and detect thermal runaways inside the DPF, a thermistor 1111 is connected to the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com