Belt press apparatus and method for high solids capture and high solids content

a belt press and solids technology, applied in the direction of filtration separation, multi-stage water/sewage treatment, separation process, etc., can solve the problems of high operating cost, low percentage of incoming solids to the belt press retained in the filter cake, and all prior art, so as to increase the flow of the mixture of solids and increase the compression in the wedge zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

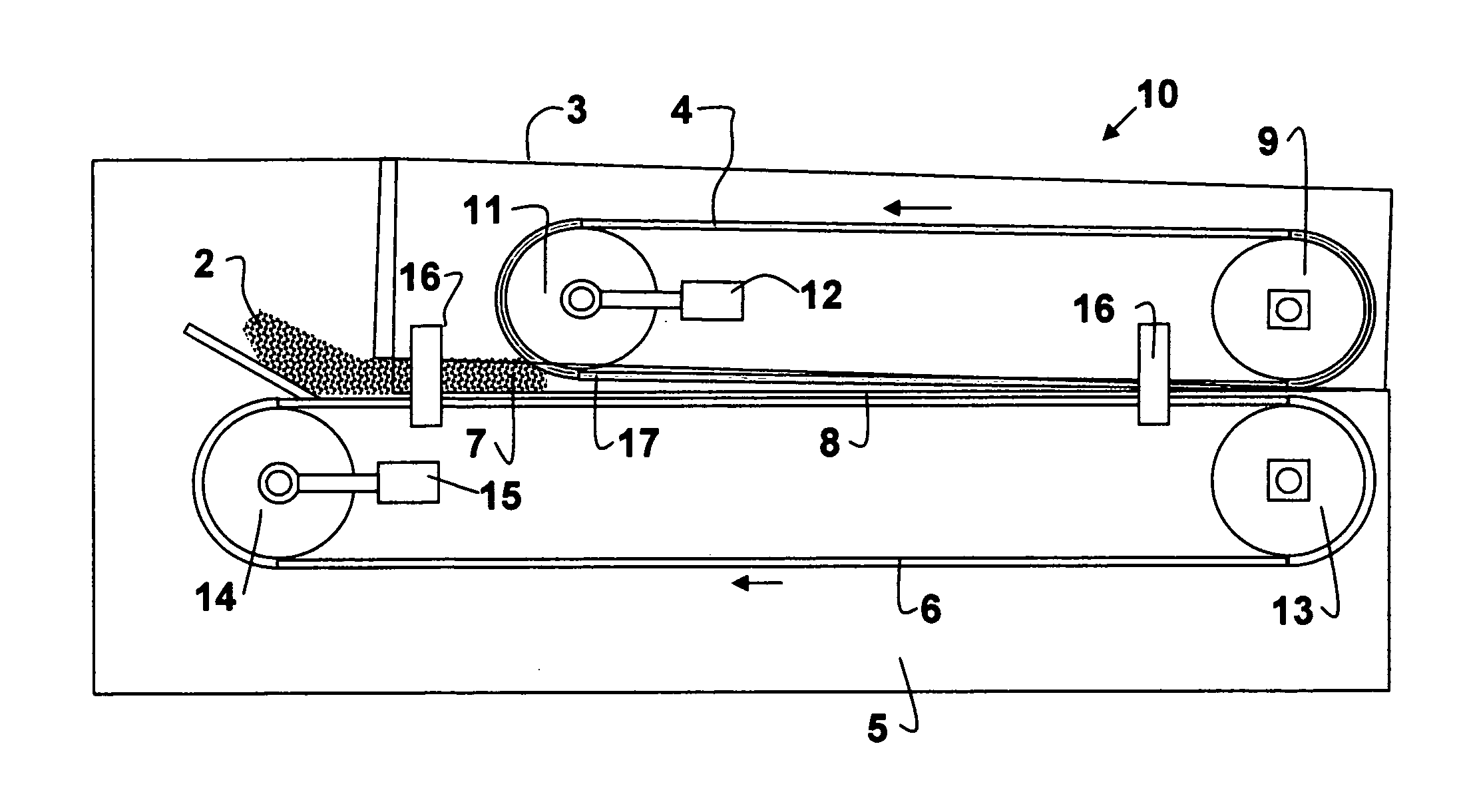

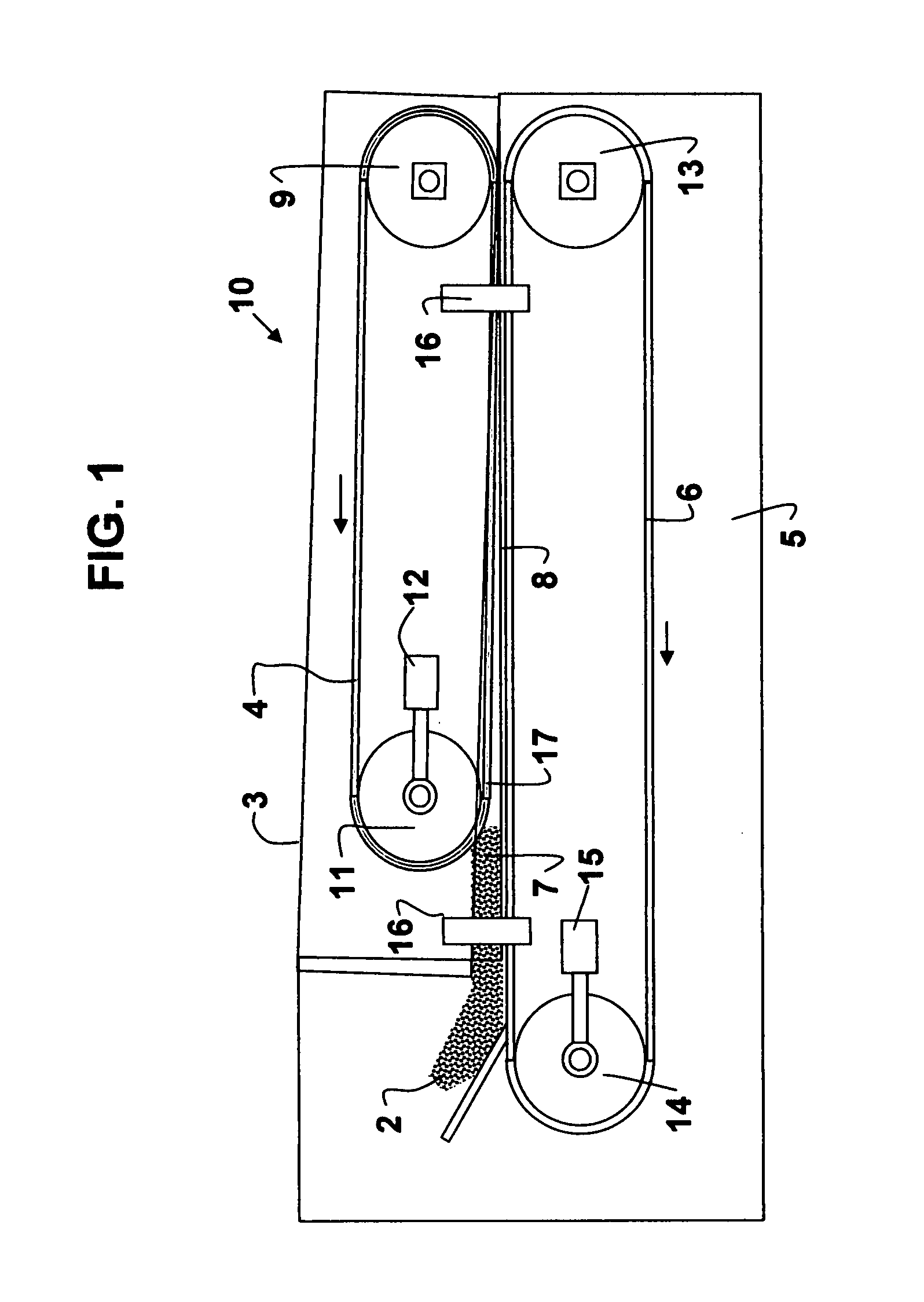

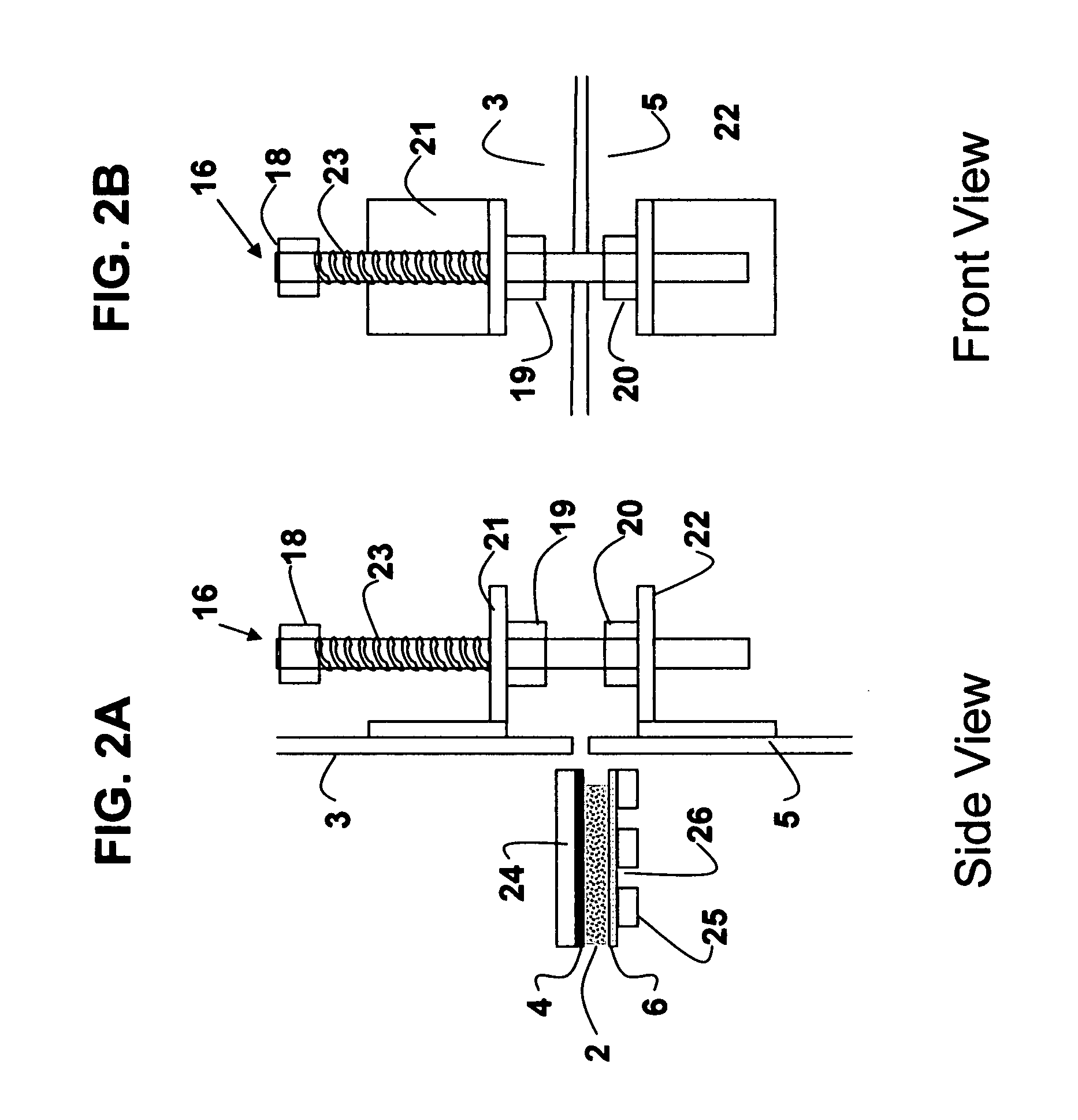

[0036]The subject of the invention is a belt press (10) for the separation of a mixture of solids and liquids (2) into a filter cake with high solids content and a means for retaining a high percentage of incoming solids in the filter cake so as to produce a separated liquid filtrate with as few solids as possible. Referring to FIG. 1, the belt press includes an upper belt assembly (3) with an endless non-permeable upper belt (4); a lower belt assembly (5) with an endless permeable lower belt (6); a gravity screening zone (7); and a wedge zone (8). In the gravity screening zone, liquid is allowed to drain through the lower permeable belt without pressure being applied by the upper belt. The wedge zone follows the gravity screening zone wherein the spacing between the two belts becomes increasingly narrow, causing pressure applied by the upper belt to increase as the spacing between the belts decreases.

[0037]The upper belt is supported by a discharge-end roller and drive (9) and an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com