Transmissive disk, manufacturing method thereof, and levitation measurement apparatus using transmissive disk

a technology of transmissive disk and manufacturing method, which is applied in the direction of instruments, coatings, data recording, etc., can solve the problems of affecting the measurement accuracy of the levitation amount and the inability to obtain an accurate amount of levitation, and achieve the effect of less subject to damage and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

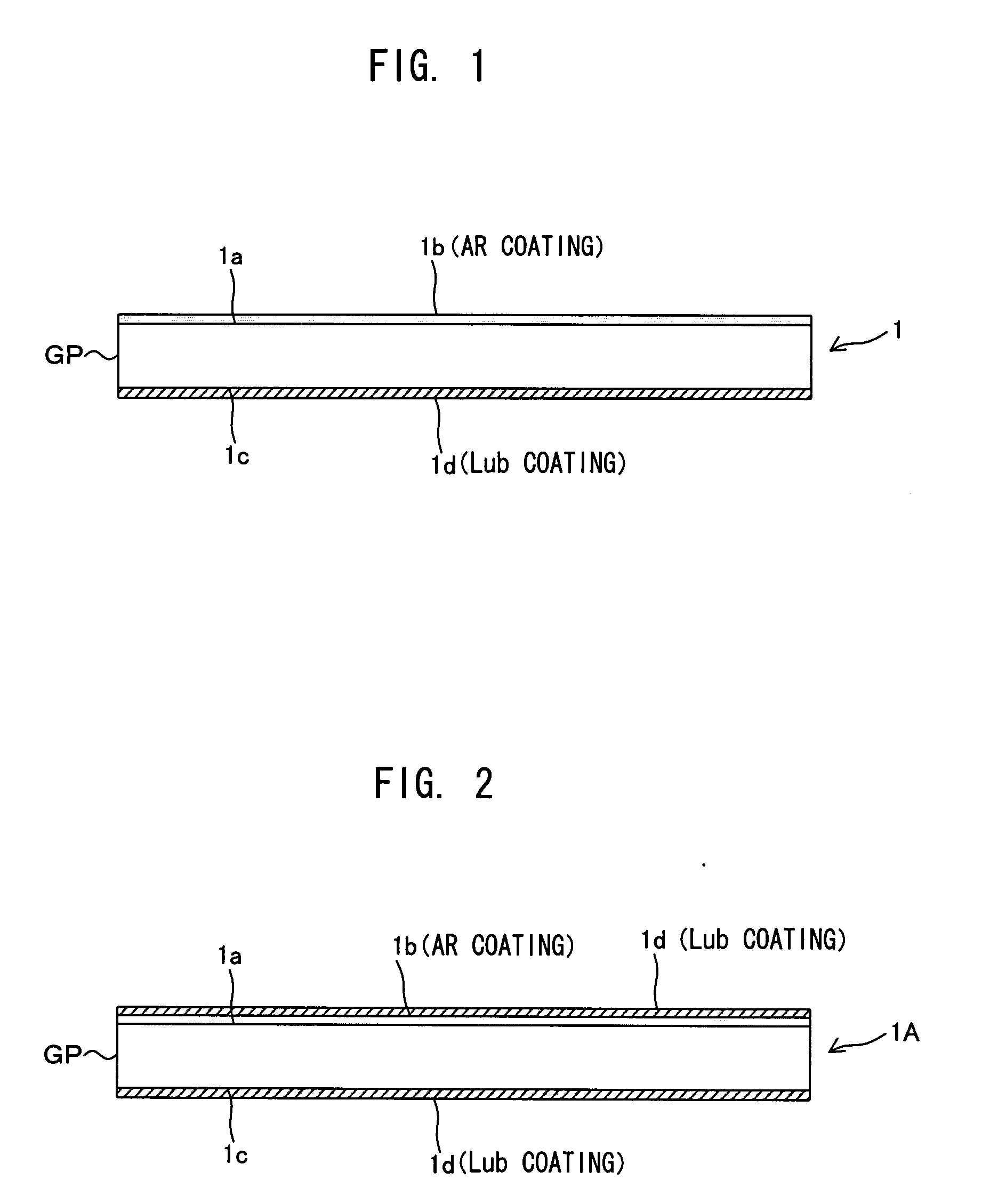

[0022]FIG. 1 is a side view showing a glass disk which is a transmissive disk according to a first embodiment of the present invention.

[0023]A glass disk 1 has a first side 1a of a disk (glass plate GP which is a transmissive plate) to which AR coating 1b has been applied and a second surface 1c thereof to which Lub (lube) coating 1d which is lubricant coating has been applied.

[0024]The AR coating 1b has been known as surface treatment applied to a glass such as a lens or display (CRT) and is treated with special surface treatment in order to suppress reflection of indoor lighting or outside light in the display surface of a CRT. In this first embodiment, two types of thin films having different refractive indexes are coated on the surface of the first side 1a of the glass disk 1 to thereby prevent reflection of outside light in the display surface. The AR coating 1b has a film thickness determined by the refractive indexes of materials used and wavelength of light to be transmitted...

second embodiment

[0026]FIG. 2 is a side view showing a glass disk which is a transmissive disk according to a second embodiment of the present invention.

[0027]In a glass disk 1A according to the second embodiment, the Lub coating 1d which is the same as the Lub coating 1d shown in the first embodiment is applied to the upper surface of the first side 1a of the glass disk according to the first embodiment to which the AR coating 1b has been applied.

[0028]The AR coating 1b is applied to the first side 1a of the a disk (glass plate GP) as a glass disk in the case of the first embodiment and then the entire disk is immersed in the lubricant (Lub) to obtain the glass disk 1A according to the second embodiment. According to the above manufacturing method, it is possible to extremely easily achieve Lub coating as well as to prevent both side surfaces of the glass disk 1 from being damaged.

third embodiment

[0029]In a third embodiment, a head (e.g., magnetic head) levitation measurement apparatus using the glass disk according to the first or second embodiment will be described.

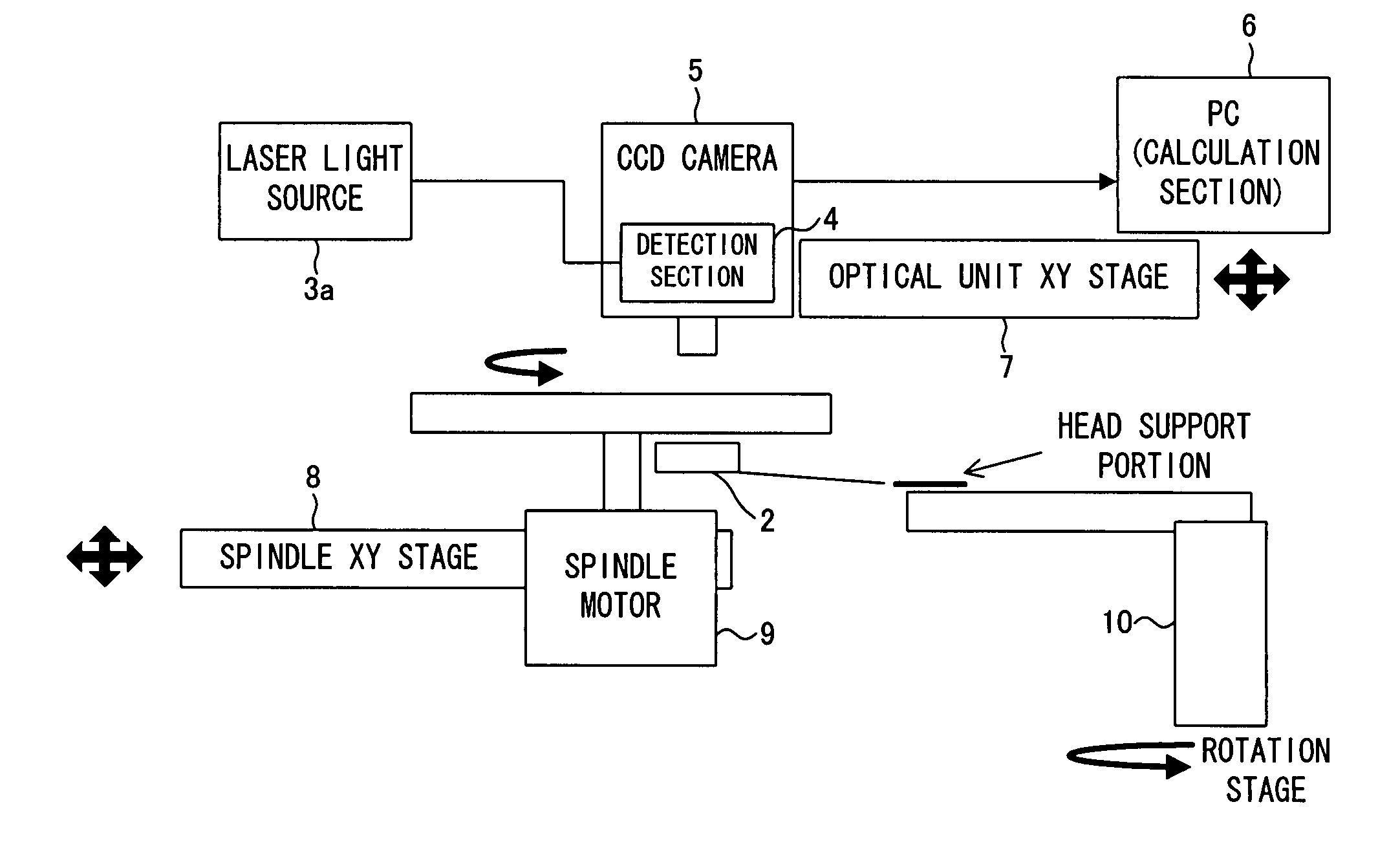

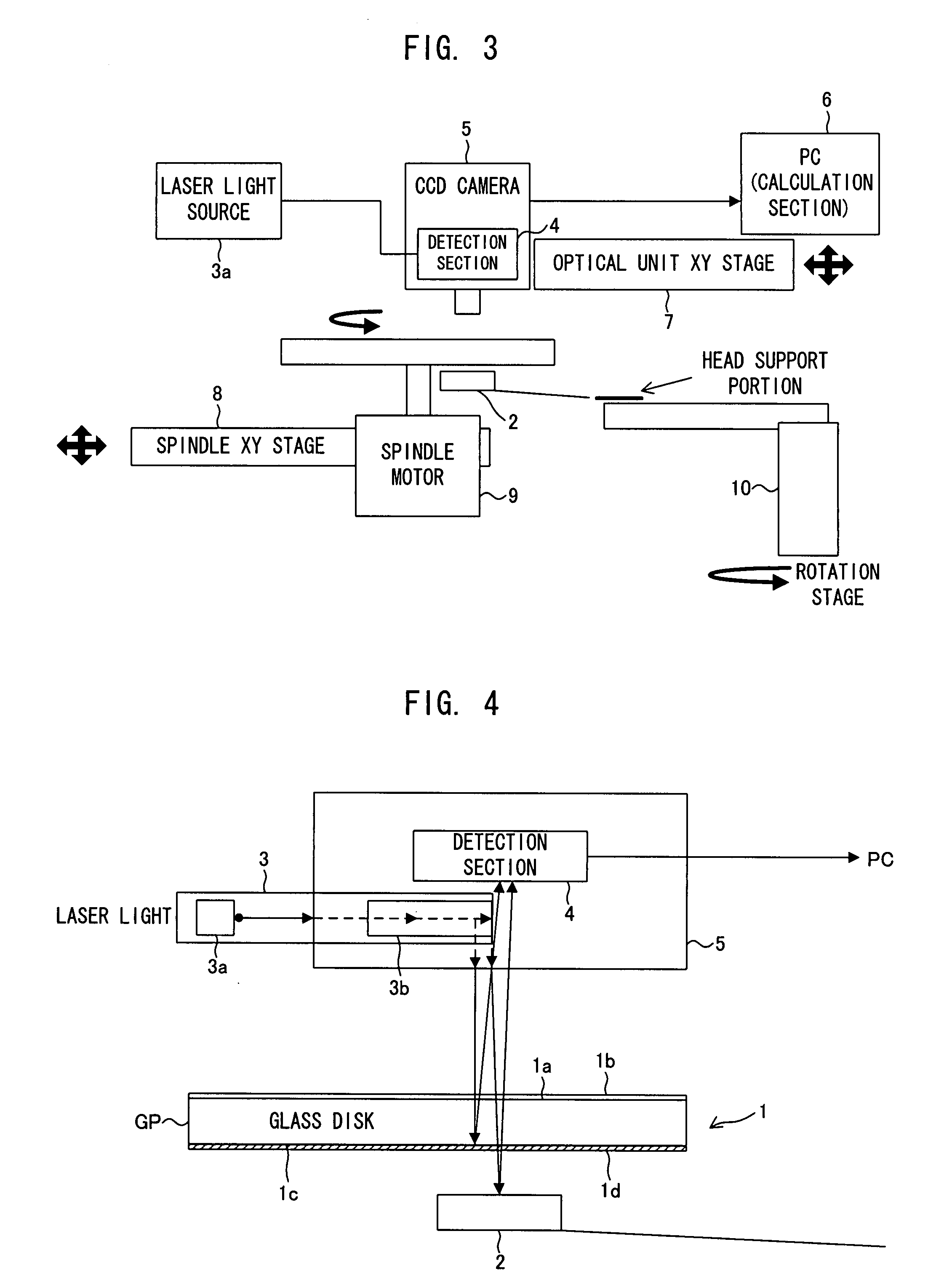

[0030]FIG. 3 is a block diagram showing the entire configuration of a magnetic head levitation amount measurement apparatus, and FIG. 4 is a partially enlarged view of FIG. 3 which shows a measurement principle.

[0031]The levitation measurement apparatus shown in FIG. 3 includes the glass disk 1 (1A) which is a transmissive disk according to the first embodiment (or second embodiment), a projector 3, a CCD camera 5, and a calculation section (PC) 6. The projector 3 is disposed opposite to the first side 1a of the glass disk 1A and includes a laser light source 3a and an optical system 3b which project light, through the glass disk 1, to a magnetic head 2 (slider) which is levitated from the surface of the second side 1c of the glass disk 1. The CCD camera 5, which includes a detection section 4 which detects inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com