Easy cut suspension grid

a technology of suspension grid and grid elements, which is applied in the direction of girders, joists, trusses, etc., can solve the problems of no practical or cost-effective way to prefabricate an installation or even a part of an installation, no convenient workbench or like table to support the grid elements, and no installation work can be done on the actual floor surface or by an installer standing directly on the floor. , to achieve the effect of reducing labor intensity, reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

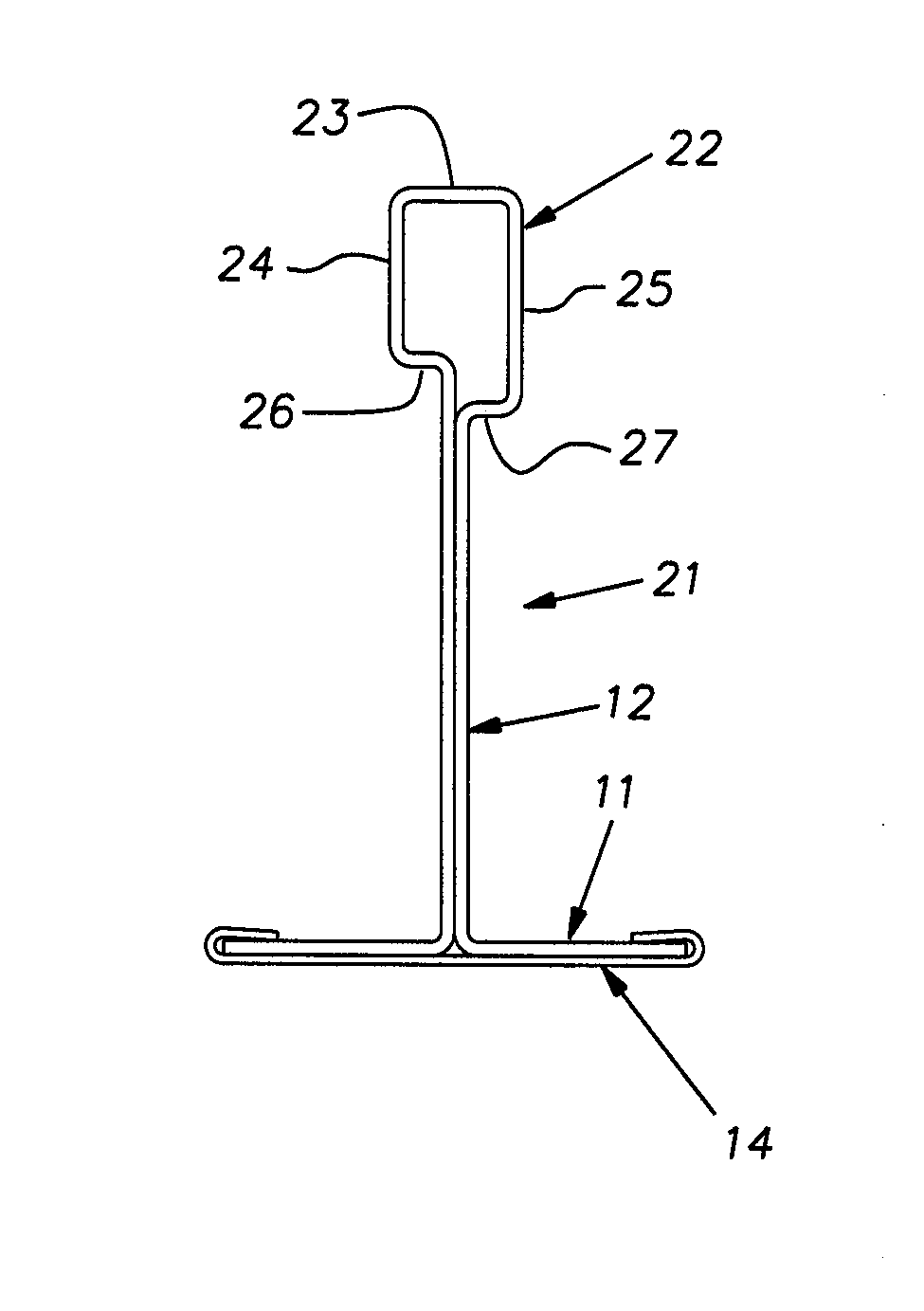

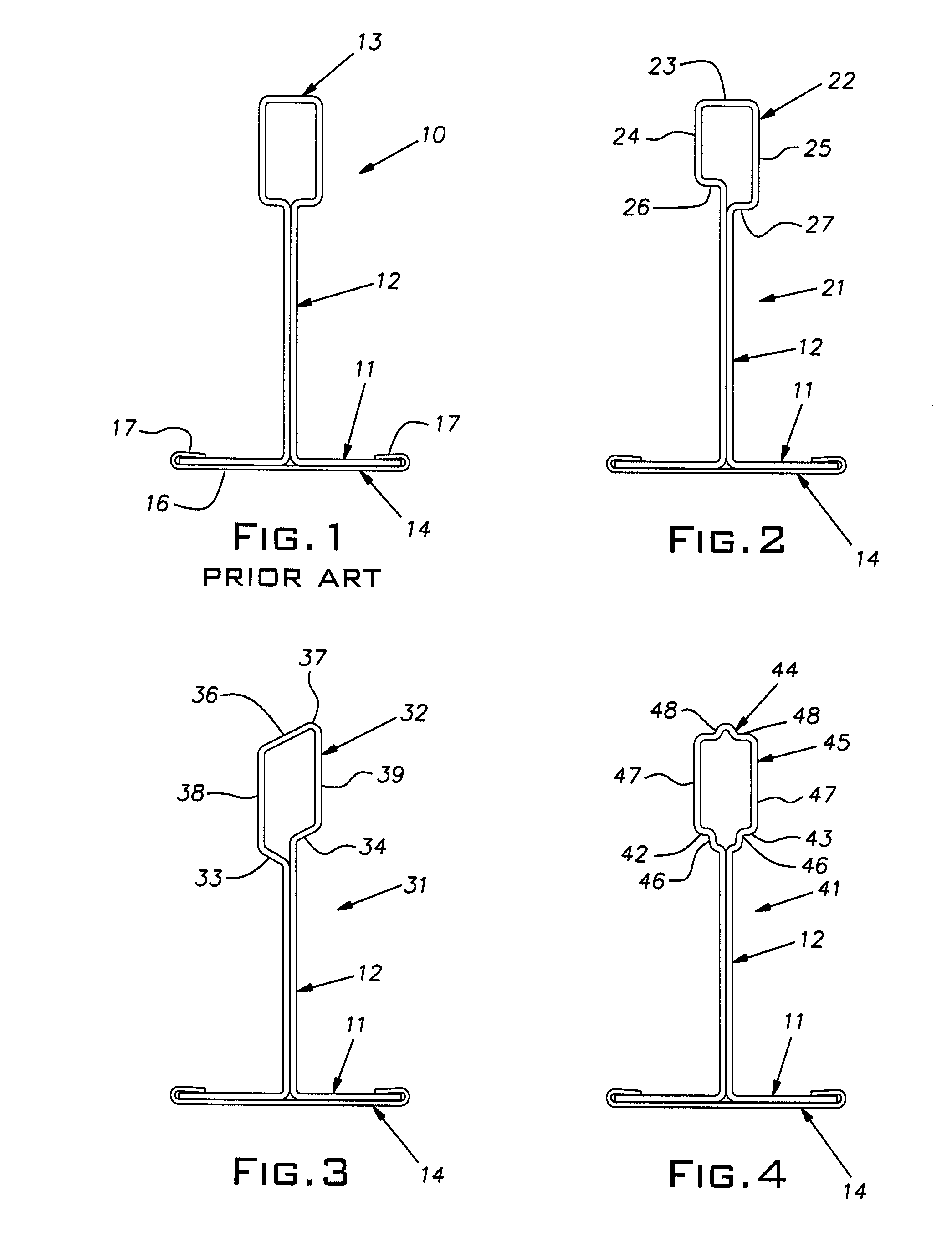

[0010]FIG. 1 illustrates a traditional prior art grid tee or runner 10 in profile or cross-section. This prior art style grid tee 10 and the grid tees described hereinbelow incorporating the present invention are elongated shafts assembled into a rectangular gridwork typically suspended from overhead or superstructure and on which tiles are mounted to construct a suspended ceiling. The gridwork, typically, comprises main tees and intersecting cross tees; grid modules are typically 2 foot by 2 foot or 2 foot by 4 foot or metric equivalent. The main tees are provided with regularly spaced slots in their mid-section or web that accept connectors provided on the ends of cross tees as is customary in the industry. Main tees are connected end-to-end with suitable end connectors, known in the art, to span the ceiling area. The main and cross tees can have the same cross section or profile or the cross tees can have a lighter duty section such as having a reduced height.

[0011]The grid tee 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com