Encased Snack

a snack and encased technology, applied in the field of encased snacks, can solve the problems that no prior art snack endures heat treatment, and achieve the effects of improving taste, appealing appearance, and improving shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Filled Soft or Crunchy Cookie / Cereal Bars

[0070]Filled soft or crunchy cookie / cereal bars were prepared according to the following protocol and using the ingredients and amounts shown in Table 1.

[0071]Procedure:

[0072]1. Shred cookies or cereal / dried fruit or nuts-based muesli mix into crumbs via a Thermomix (Vorwerk) to target crumb size of 1-2 mm.

[0073]2. Mix-in dry food ingredients (i.e. egg white powder, biscuit flavour Silesia, nut flavour Quest, Glucose syrup type binder, cold swell pre-gelatinized starch or flour) to create crumb material.

[0074]3. Spray water directly into the mix and distribute by gently mixing.

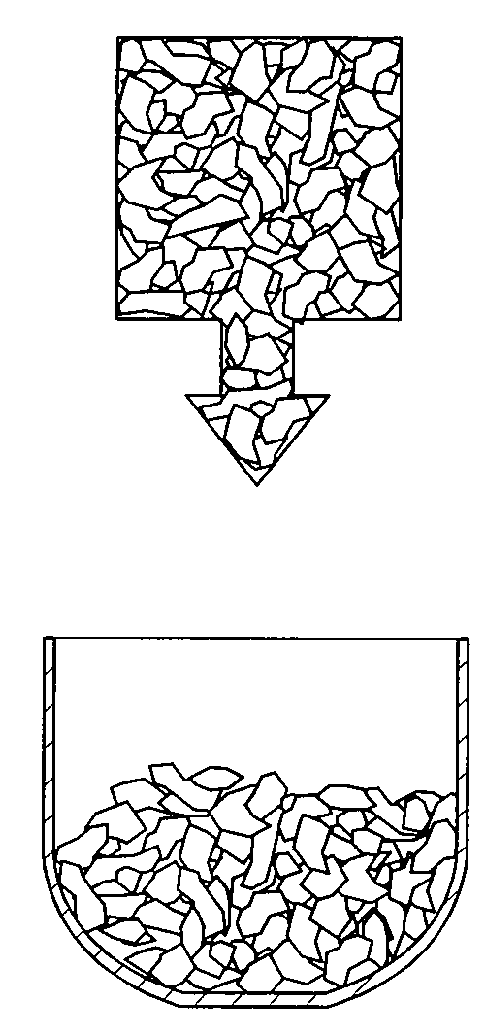

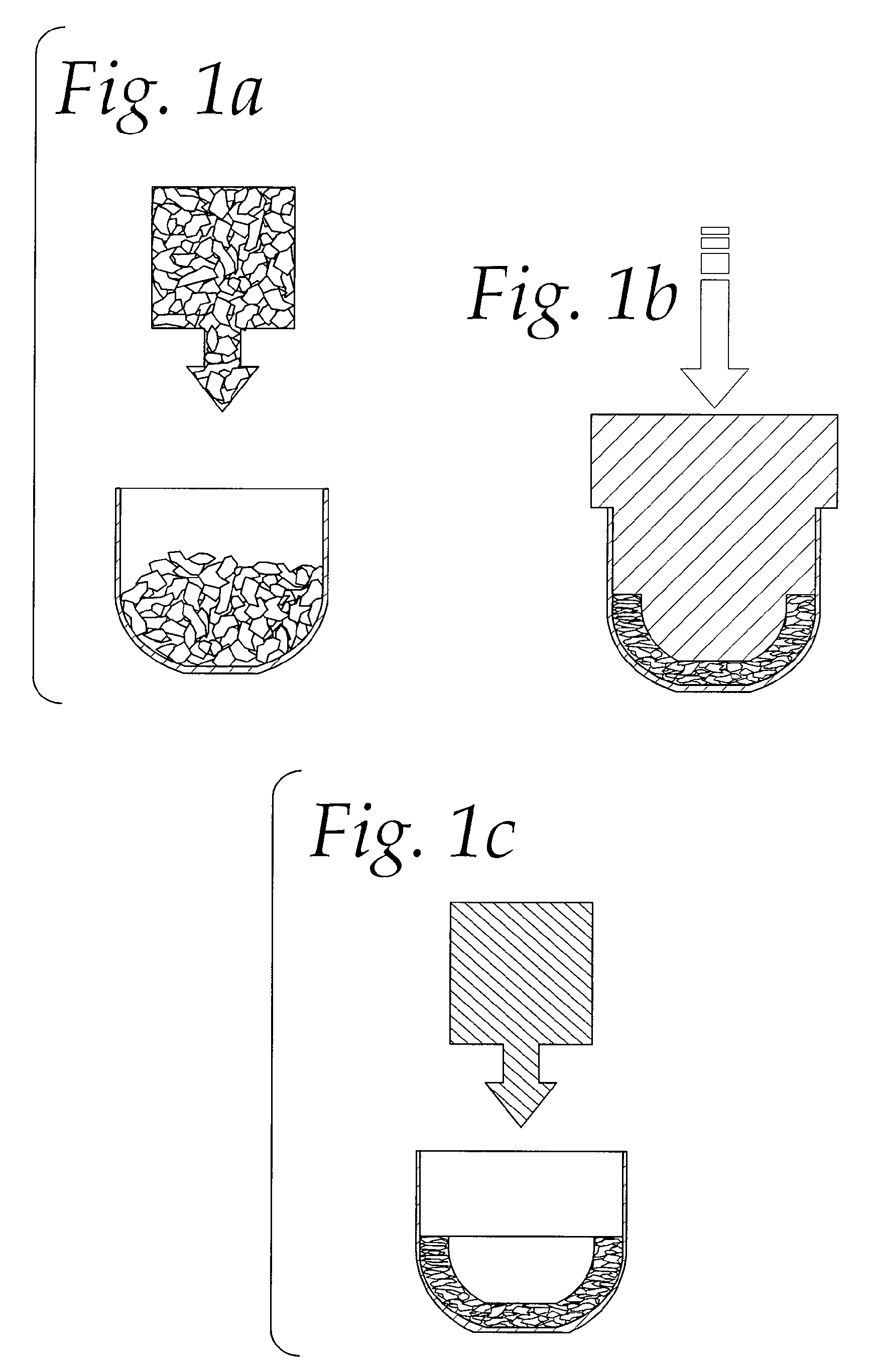

[0075]4. Fill crumb material thus obtained and optionally nuts into the lower die as first layer, press first upper die at ambient temperature at around 6 bar for 2 seconds to create shell, add chocolate or milk-cream filling into the shell.

[0076]5. In the case of chocolate filling: cool to solidify the chocolate via 5 min cooling with blasting cold air.

[...

example 2

Filled Whole Wheat Bagel or Bar

[0082]Filled whole wheat bagels or bars were prepared according to the following protocol and using the ingredients and amounts shown in Tables 2 and 3.

[0083]Procedure:

[0084]1. Knead all components of table 2 in Diosna kneader.

[0085]2. Proofing for one hour.

[0086]3. Cook dough indirectly in Stephan cutter at 67° C. for 2 min, cool and shred at 45° C.

[0087]4. Add 100 gram Purafarin SD and continue shredding while cooling; take out when loose dough crumbs are formed;

[0088]5. Shred normal bulk white bread for a few second in a Thermomix (Vorwerk).

[0089]6. Mix loose dough crumbs with normal white bread crumbs in given ratio (see table 3) by a gentle tumbler mixer (no kneading).

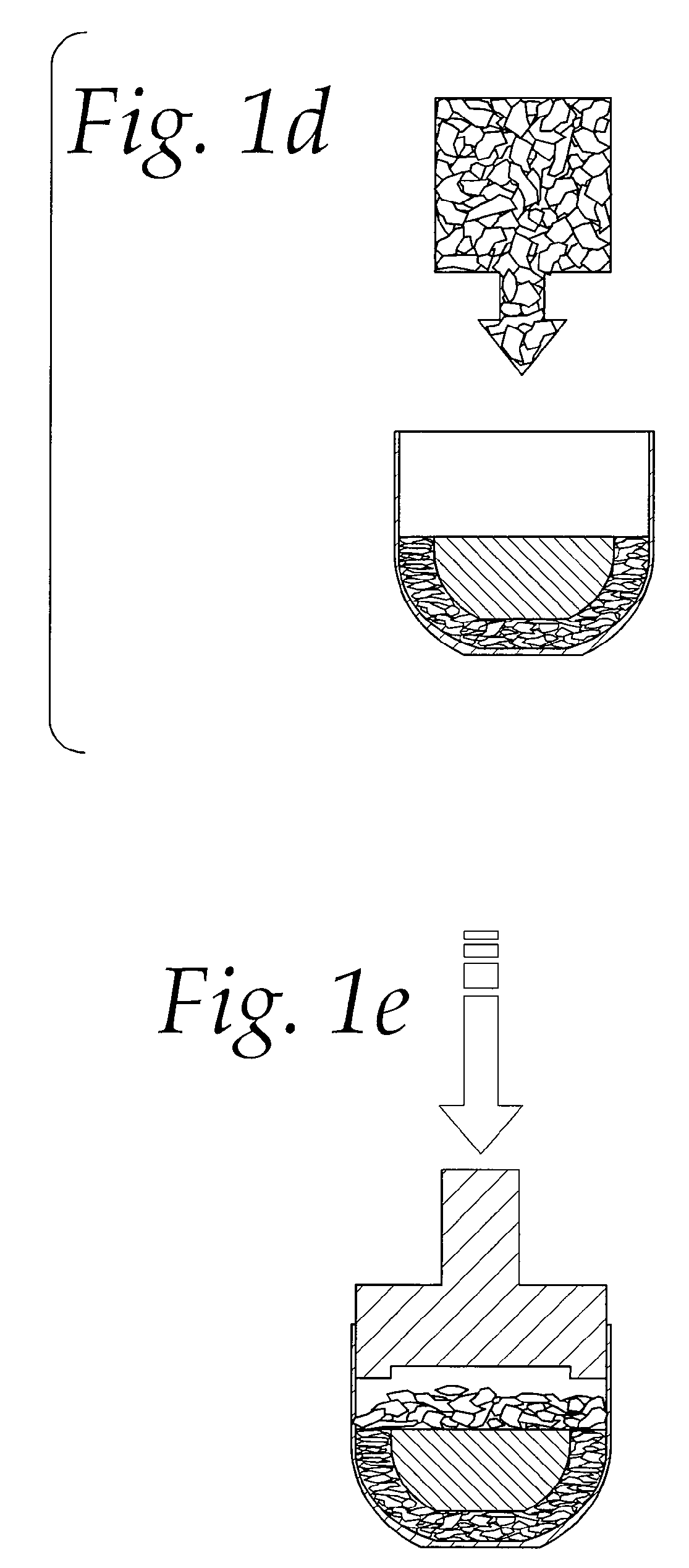

[0090]7. Add seeds to metal bar mould.

[0091]8. Fill crumb material obtained under item 6 (see table 3) into lower die, press first upper die at 65° C. at 4 bar for 1 second to create shell, place filling (see table 3) into the shell, add crumb mix (see table 3) on top and fix with ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inversely angle α | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com