Tandem Washing System Configuration For Recycling Detergent & Water

a technology of detergent and water, which is applied in the direction of other washing machines, washing apparatus, textiles and paper, etc., can solve the problems of pathogen growth, no prior art device is suitable for economic use of resources, and heavy use of resources, so as to improve wash quality and optimise operational inputs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

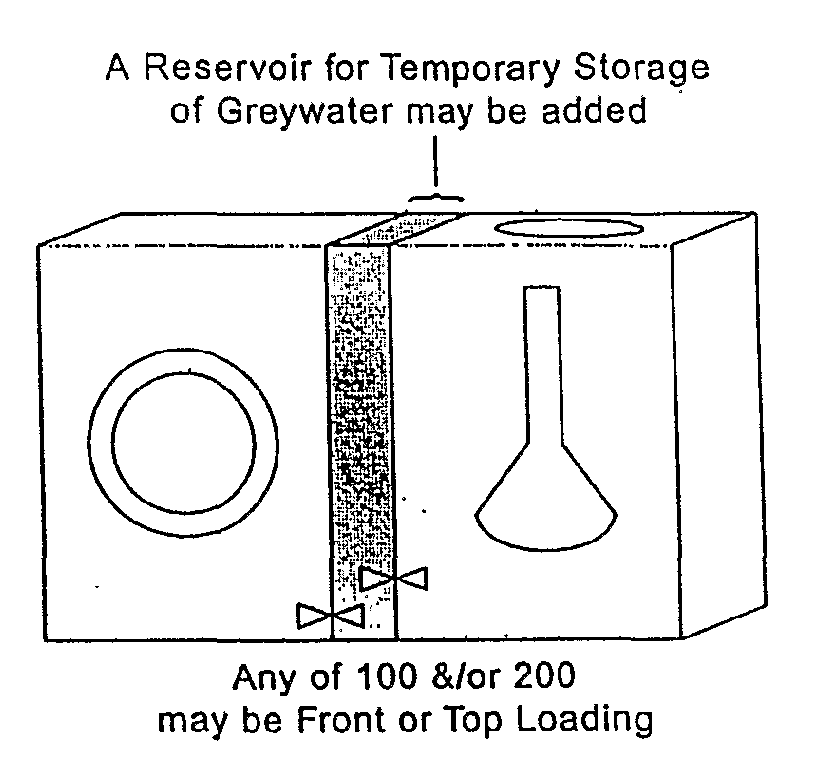

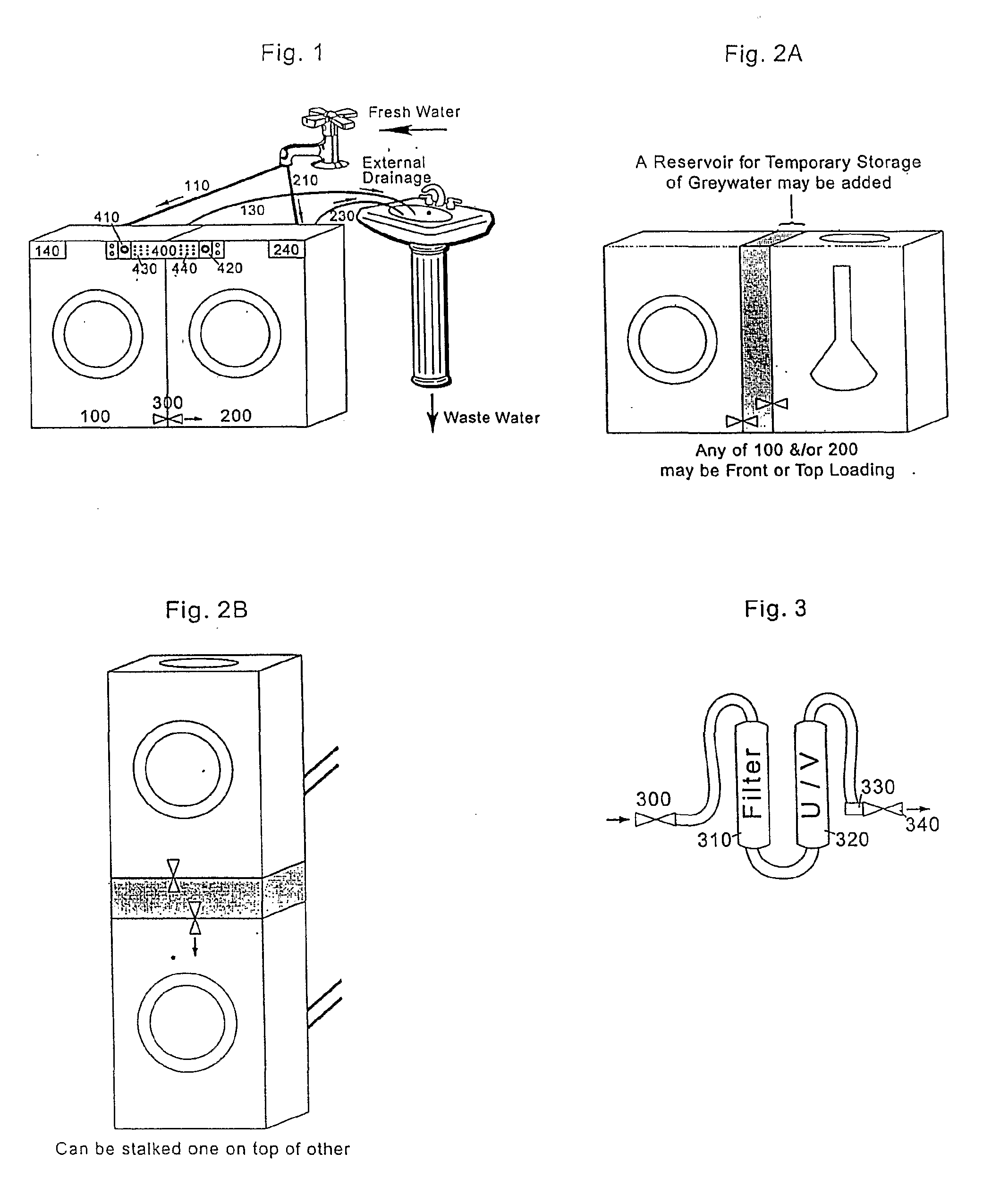

[0021]In FIG. 1 there is a twin assembly of Washing Machines assigned with reference numerals (100 and 200). The machines (100, 200) are connected through a channel means having a two-way solenoid valve means (300), for channelling water from one to another. The input to the channel (300) passes through a Sieve and / or Filtration device (310), to remove suspended impurities like Lint and other large particles. Additionally, the channel means passes through an Ultraviolet or Gamma rays irradiation chamber (320) to remove pathogens. The channel is provided with a back-flush device taking input water from a tap and discharging back-flushed water into a drainage.

[0022]Both the washing machines (100, 200) have independent tap water inlets (110, 210) and effluent drainage pipes (130, 230).

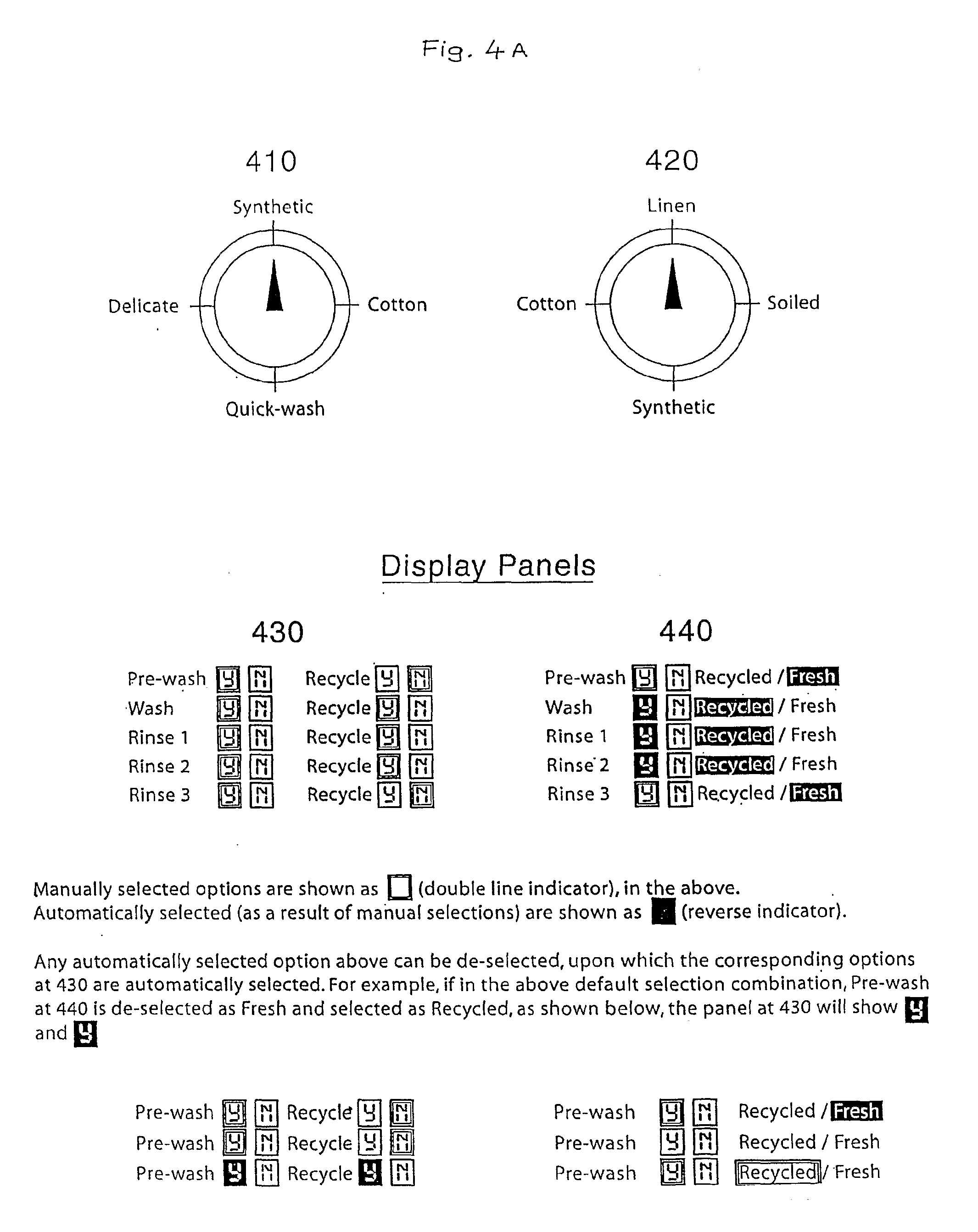

[0023]Both the machines (100, 200) are controlled by a single controller (400) with a pre-programmed logic and a default setting that can be changed through electronic push buttons (410) and knobs (420), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com