Method and Apparatus for Felting Three Dimensional Objects

a three-dimensional object and apparatus technology, applied in the field of felting, can solve the problems of shrinkage, surface appearance softening, and the creation of three-dimensional forms only by indirect methods, and achieve the effects of smooth surface texture, less shrinkage, and more direct and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Felting Method

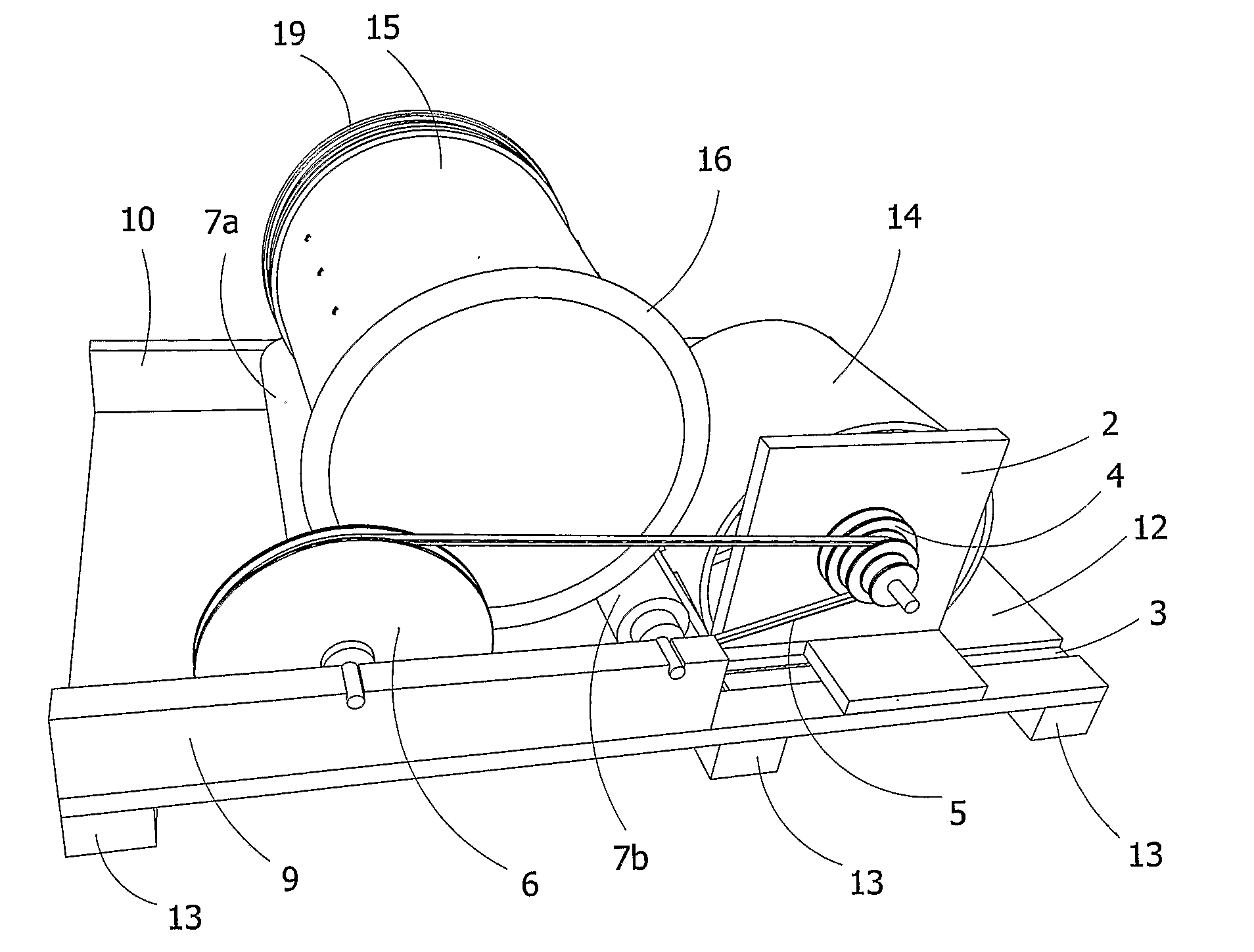

[0087]With reference to FIG. 1, a method for felting a three-dimensional object is provided in which an apparatus in accordance with the invention is also employed.

Wool Wrapping

[0088]In accordance with the method shown in FIG. 1, the object or blank to be felted is first wrapped with wool batting in step A. Multiple layers of wool batting are built up around the object, with each subsequent layer of wool batting placed upon the previous layer with the wool fibres preferably misaligned between each layer. The object should be wrapped with sufficient batting to result in the desired felt thickness (approximately 1½ to 2 inches of batting will compress down to ¼ to ⅜ inch thick of hard felt). The object that is to be felted may be a solid object such as a ball, or may be an inflated blank having an appropriate shape and size for felting.

Protective Casing

[0089]A protective casing is then applied B to the wrapped object to hold the wool in place, preventing unravelling. In ...

example 2

Apparatus

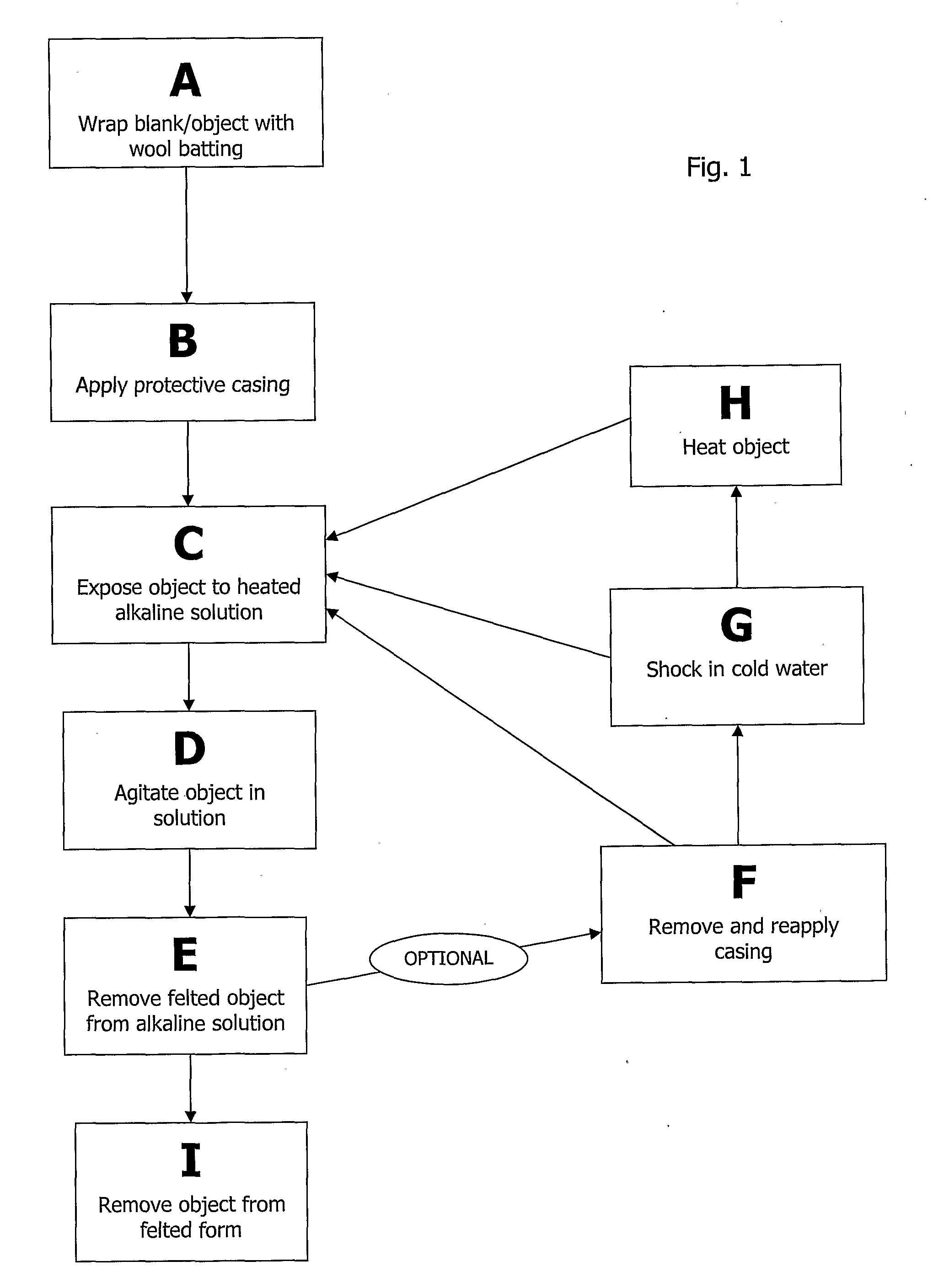

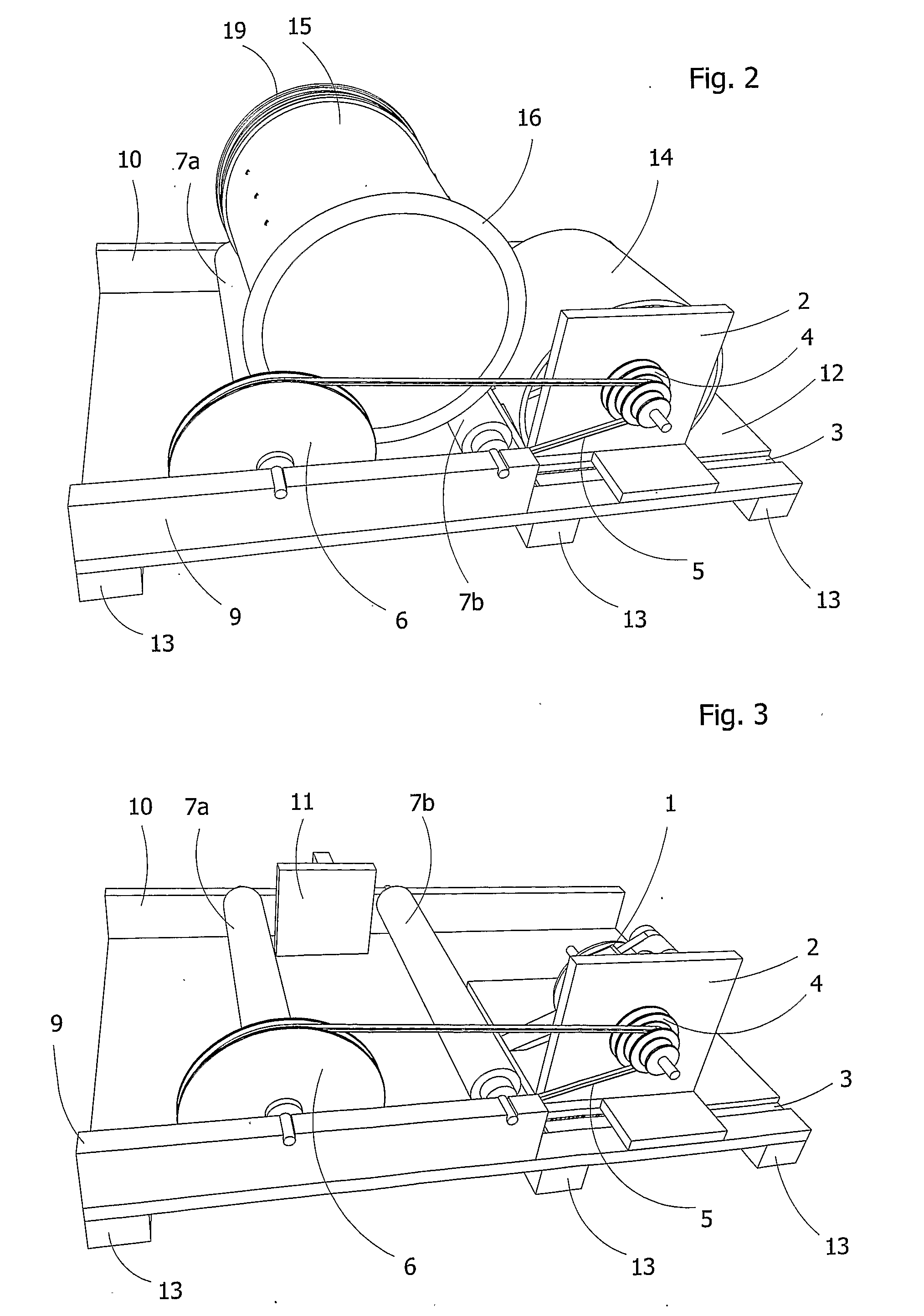

[0122]An embodiment of a machine for use with the above method is shown in FIGS. 2 through 5.

Motor

[0123]The motor 1 drives the v-belt 5 that in turn drives the pulley 6 attached to the active roller 7a, thereby rotating the drum 15 as it lies horizontally upon rollers 7a, 7b. The motor 1 should be selected so as to provide ample power for the scale of the machine, allowing the machine to function and not labour under the weight of the drum and its contents. A weak motor may overheat and may not be effective in carrying the combined weight of the drum+rubber shot+water+object. This will cause the drum to shuffle between the rollers rather than spinning.

[0124]The motor may include various speed settings for flexibility, allowing different configurations or different sizes of drum to be used. Experimentation has shown that a motor speed of 875 rpm is suitable for small objects felted in a 12-inch diameter cylindrical drum, which results in a drum speed of approximately 33 rpm....

example 3

Apparatus

[0144]With reference to FIG. 7, a further embodiment of the apparatus is shown in which the drum 25 is a six-sided prismatic drum without interior baffles, the drum constructed of a rigid and perforated material such as perforated stainless steel, metal mesh or screening. A door or hatch 26 is present to provide access to the drum interior for placement and removal of the wrapped object along with rubber shot 20. A spray system 30 is present for receiving heated alkaline solution or steam from a reservoir 35 and spraying the solution over the drum 25 and its contents. The heated alkaline solution or steam will penetrate the drum and the wrapped object inside the drum to facilitate felting during agitation. As the heated solution or condensation arising from steam application will drip from the drum during agitation, a bottom tray 36 is present to collect the excess, which may be discarded or heated and recycled back to the reservoir 35.

[0145]The drum 25 may be driven direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com