Color changing system for structures and method therefor

a technology of color changing system and structure, applied in sustainable buildings, transportation and packaging, roof improvement, etc., can solve the problems of inelastic nature of such laminates, impractical implementation, and high cost of practice, and achieve the effect of preventing heat absorption into the underlying structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

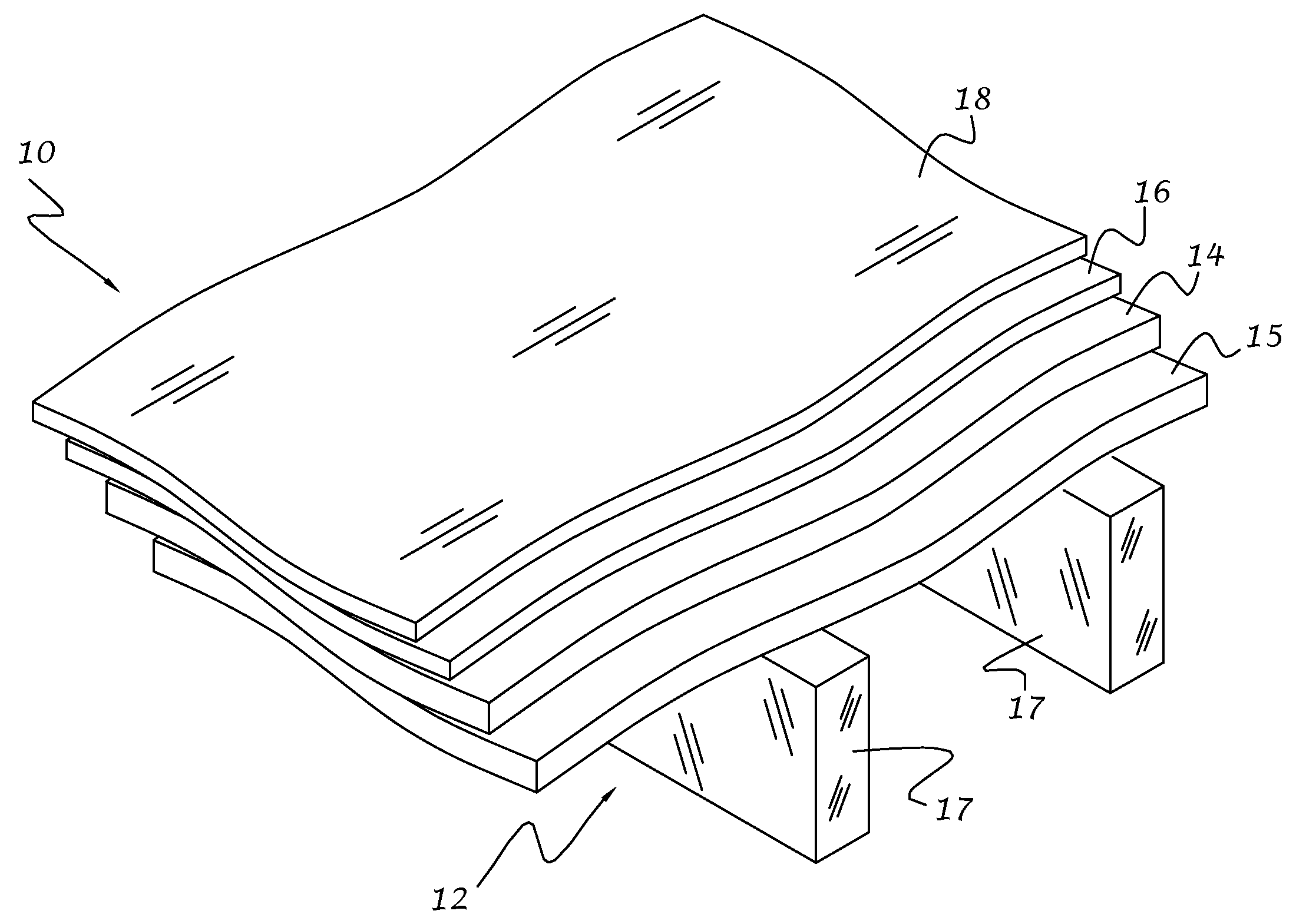

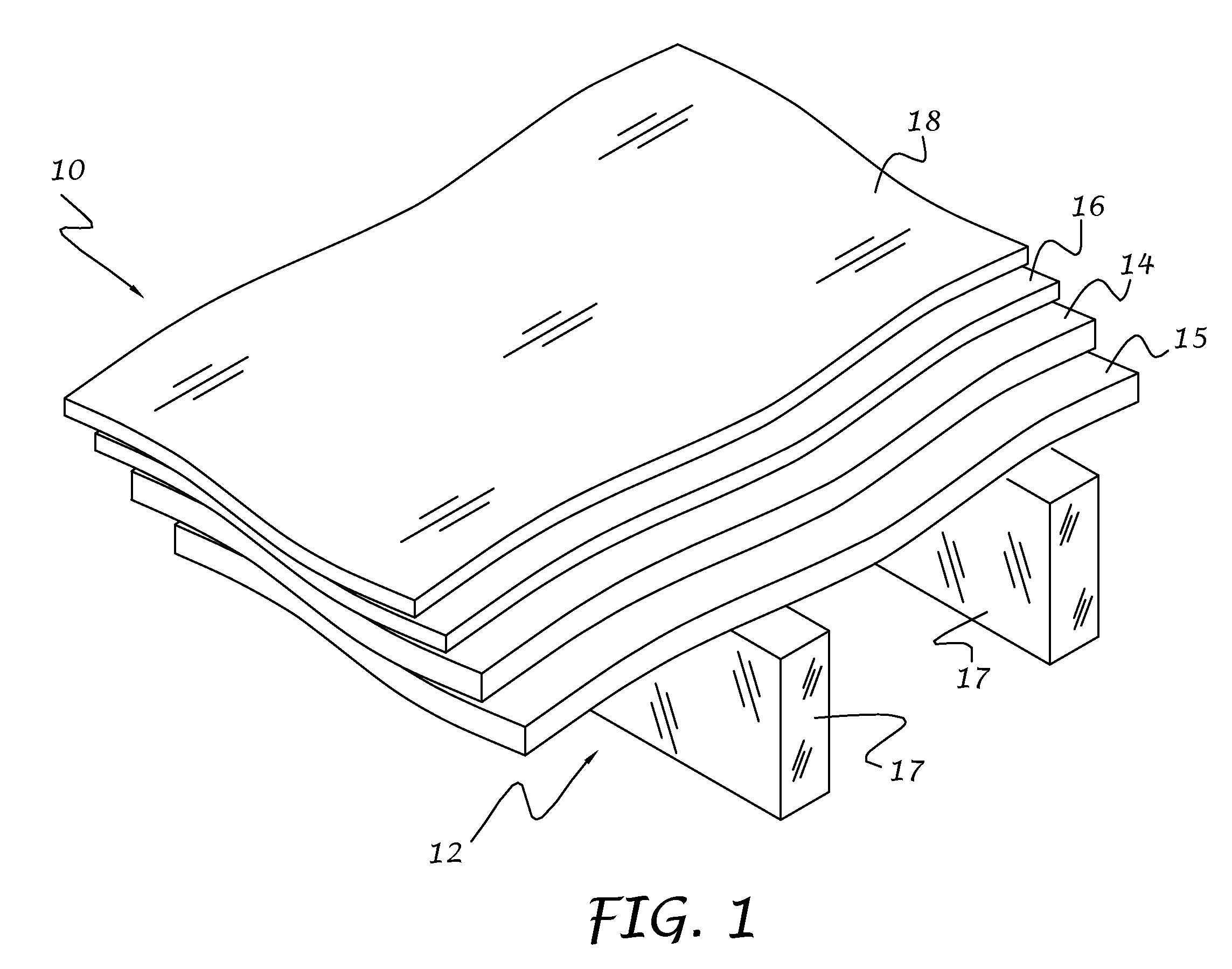

[0020]Referring to the drawings, and to FIG. 1 in particular, a coating system 10 in accordance with the present invention for application to an underlying structure 12 is illustrated. By way of example, the underlying structure 12 may include a panel 15 supported by beams 17 as used in many roof and wall constructions. The structure 12 may alternatively be constructed of a wide variety of different building materials architectural features, styles or configurations. When the panel 15 forms part of a roof structure, it may be bare, covered with shingles, gravel, waterproof coatings, laminates, or any other well-known roofing materials. The coating system 10 preferably includes a base layer 14 applied over the panel 15 and any pre-existing panel structures, a color changing layer 16 contiguous with the base layer 14, and a protective layer 18 contiguous with the color changing layer 16.

[0021]The base layer 14 preferably comprises a thermally insulative flexible material such as a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com