Antenna structure and wireless communication apparatus including same

a technology of wireless communication apparatus and antenna structure, which is applied in the direction of antenna details, electrically short antennas, antennas, etc., can solve the problems of difficulty in meeting the demand for multiple bands, and achieve the effect of increasing the electrical length of the driven radiating electrode without increasing the size reducing the size of the antenna structure, and increasing the electrical length of the driven radiating electrod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

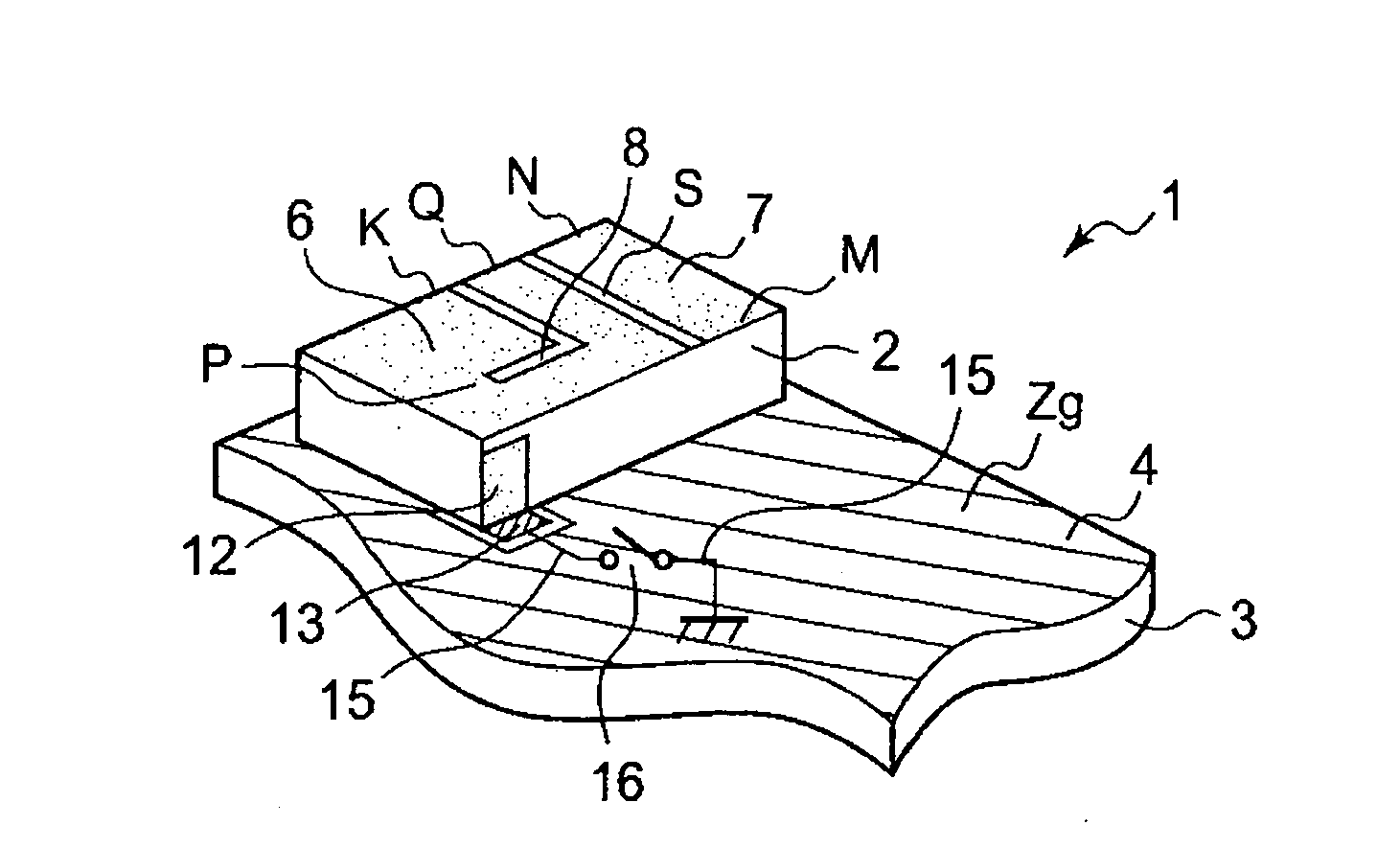

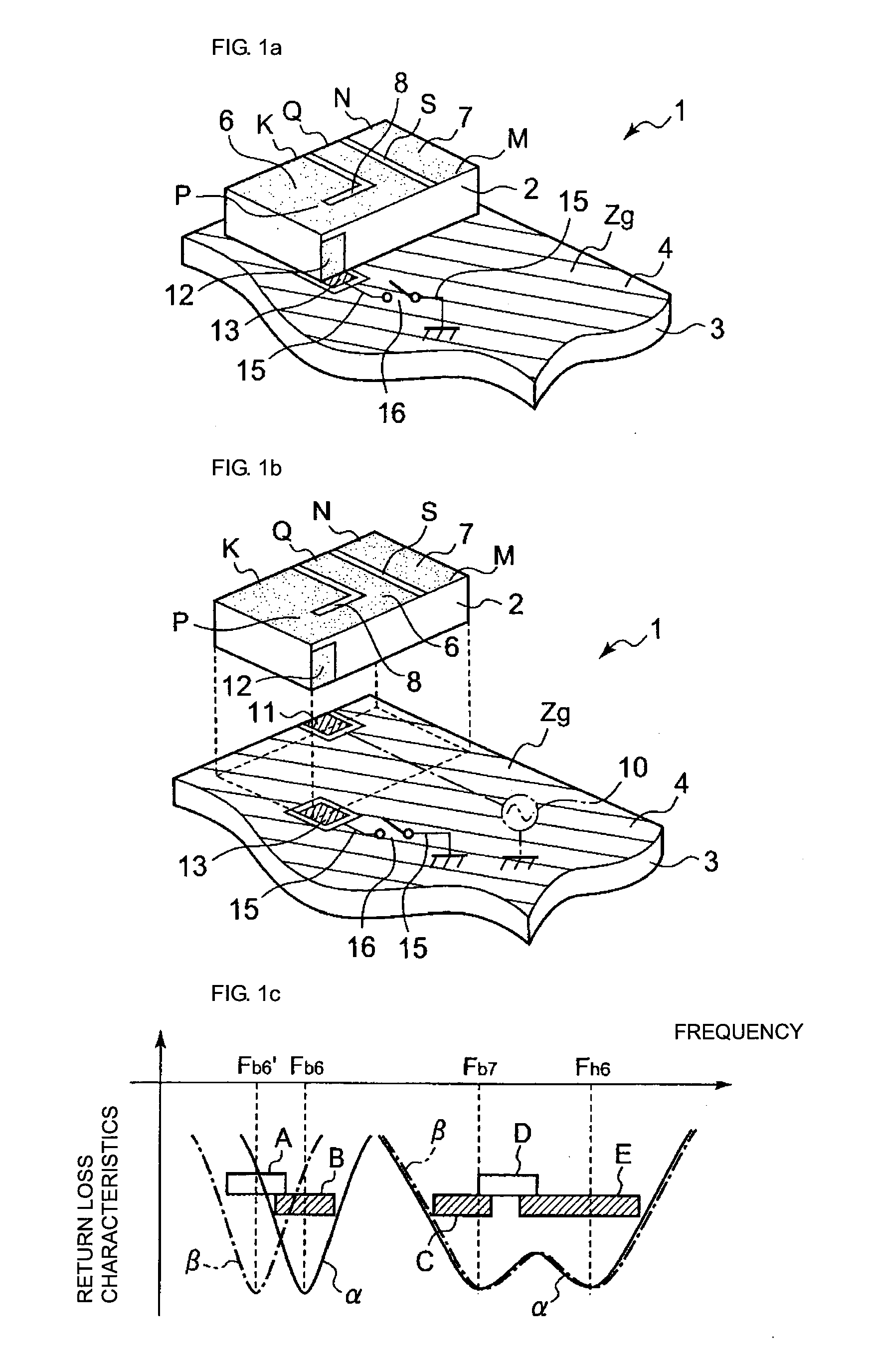

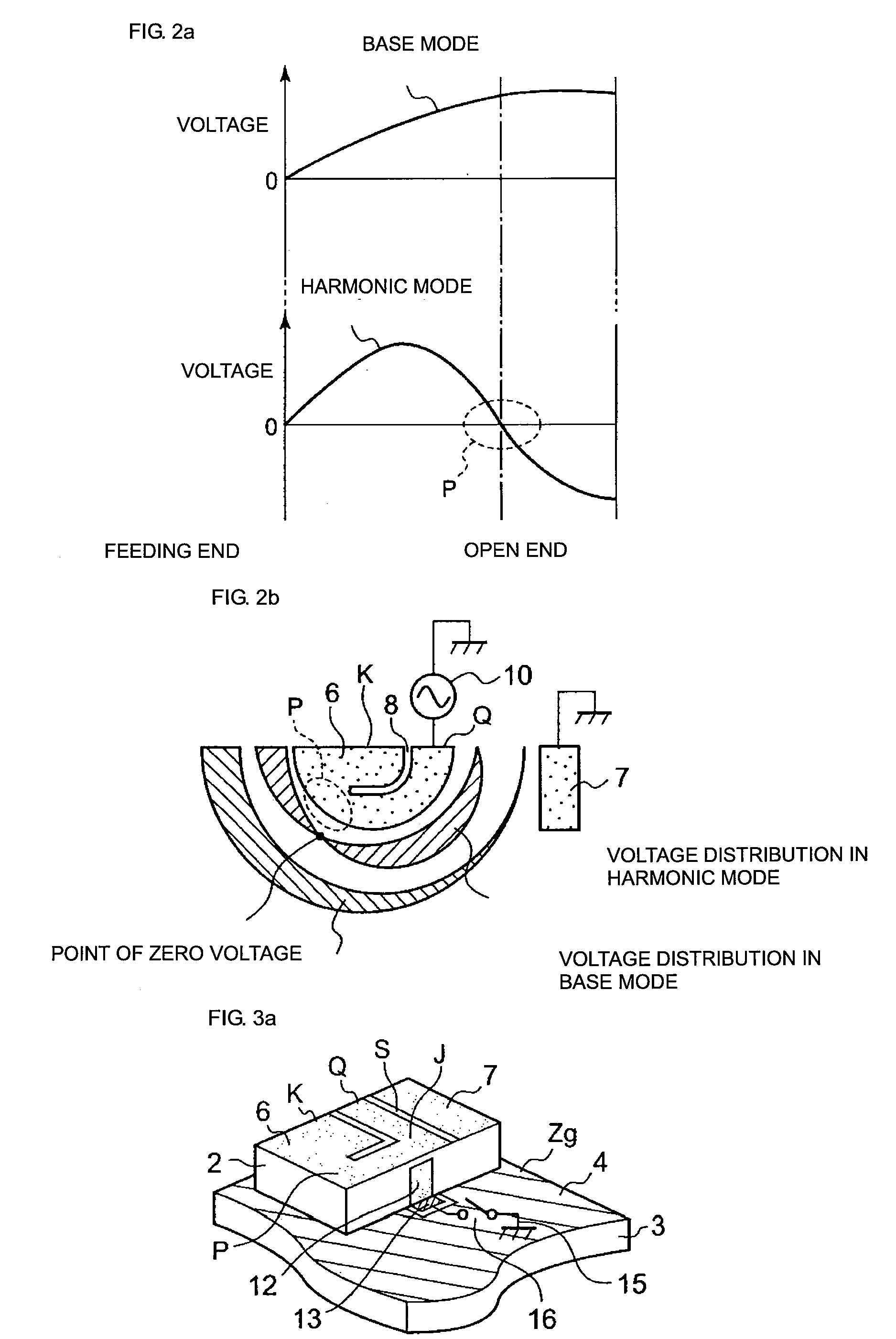

[0086]FIG. 1a is a schematic perspective view showing an antenna structure according to a first embodiment, and FIG. 1b is a schematic exploded view of the antenna structure shown in FIG. 1a. An antenna structure 1 according to the first embodiment includes a base 2 having a rectangular parallelepiped shape. The base 2 is formed of a dielectric material, and is mounted in a ground region Zg (i.e., a region where a ground electrode 4 is formed) on a circuit board 3. The dielectric material forming the base 2 is, for example, a ceramic, a resin, or a dielectric material composed of a mixture of a resin material and ceramic powder so as to have an adjusted dielectric constant. The base 2 may have either a single-layer structure or a multi-layer structure.

[0087]In the first embodiment, on a top surface of the base 2, a driven radiating or feeding electrode 6 and a parasitic radiating or non-feeding electrode 7 are disposed adjacent to each other via (i.e., separated by) a space S. The d...

second embodiment

[0108]Now, a second embodiment will be described. In the description of the second embodiment, components that are the same as those in the first embodiment are designated by the same numerals, and repeated description of the common components will be omitted.

[0109]In the second embodiment, as shown in FIG. 8a, a plurality of (two in the example shown in FIG. 8a) capacitance loading electrodes 12 (12a and 12b) are provided on the base 2. By forming a plurality of capacitance loading electrodes 12 on the base 2 as described above, it is possible to form a plurality of types of antenna structures using the base 2 having formed thereon the plurality of capacitance loading electrodes 12, the driven radiating electrode 6, the parasitic radiating electrode 7, and so forth (such a base 2 will hereinafter be referred to as an antenna component). The plurality of capacitance loading electrodes 12 may be formed so that different capacitances can be loaded in the harmonic-mode zero-voltage reg...

third embodiment

[0115]Now, a third embodiment will be described. In the description of the third embodiment, components that are the same as those in the first and second embodiments are designated by the same numerals, and repeated description of the common components will be omitted.

[0116]In the third embodiment, in addition to the configuration of the first or second embodiment, the parasitic radiating electrode 7 has a loop-shaped current path. For example, in an example shown in FIG. 9a, the parasitic radiating electrode 7 has a slit 26 formed so as to cut in from an end edge of the parasitic radiating electrode 7. At the electrode end edge on the side of the opening of the cutting of the slit 26, with the slit 26 in the middle, one end N serves as a shorted end electrically connected to the ground electrode 4, and the other end M serves as an open end. A current path between the shorted end N and the open end M is a loop-shaped path extending around the slit 26 and connecting the feeding end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com