Integrated method for producing a fuel component from biomass and system therefor

a technology of biomass and fuel components, applied in the direction of fuels, combustible gas production, energy input, etc., can solve the problems of increasing the price of conventional transportation fuels, affecting and causing significant deleterious effects on the current transportation capability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

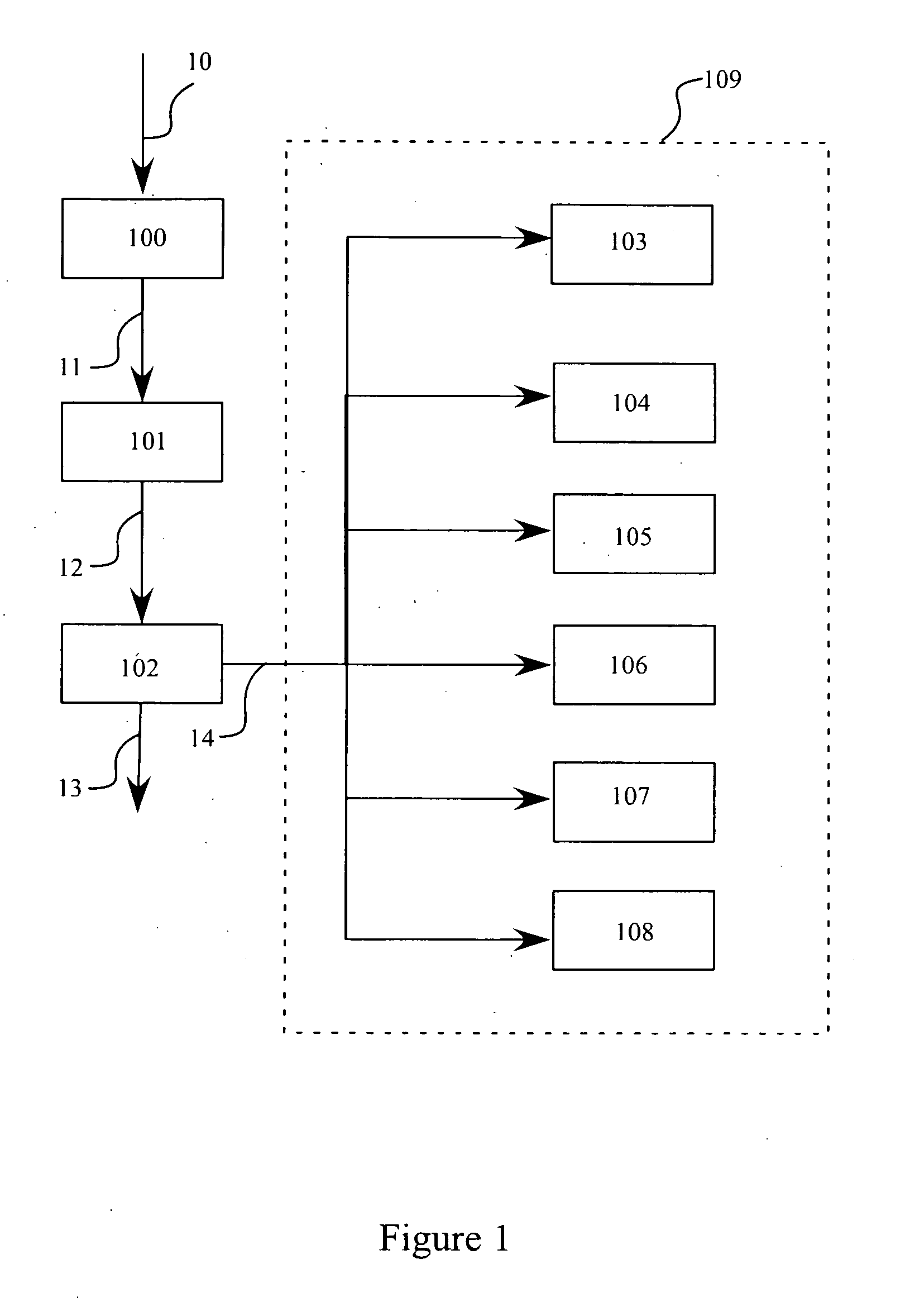

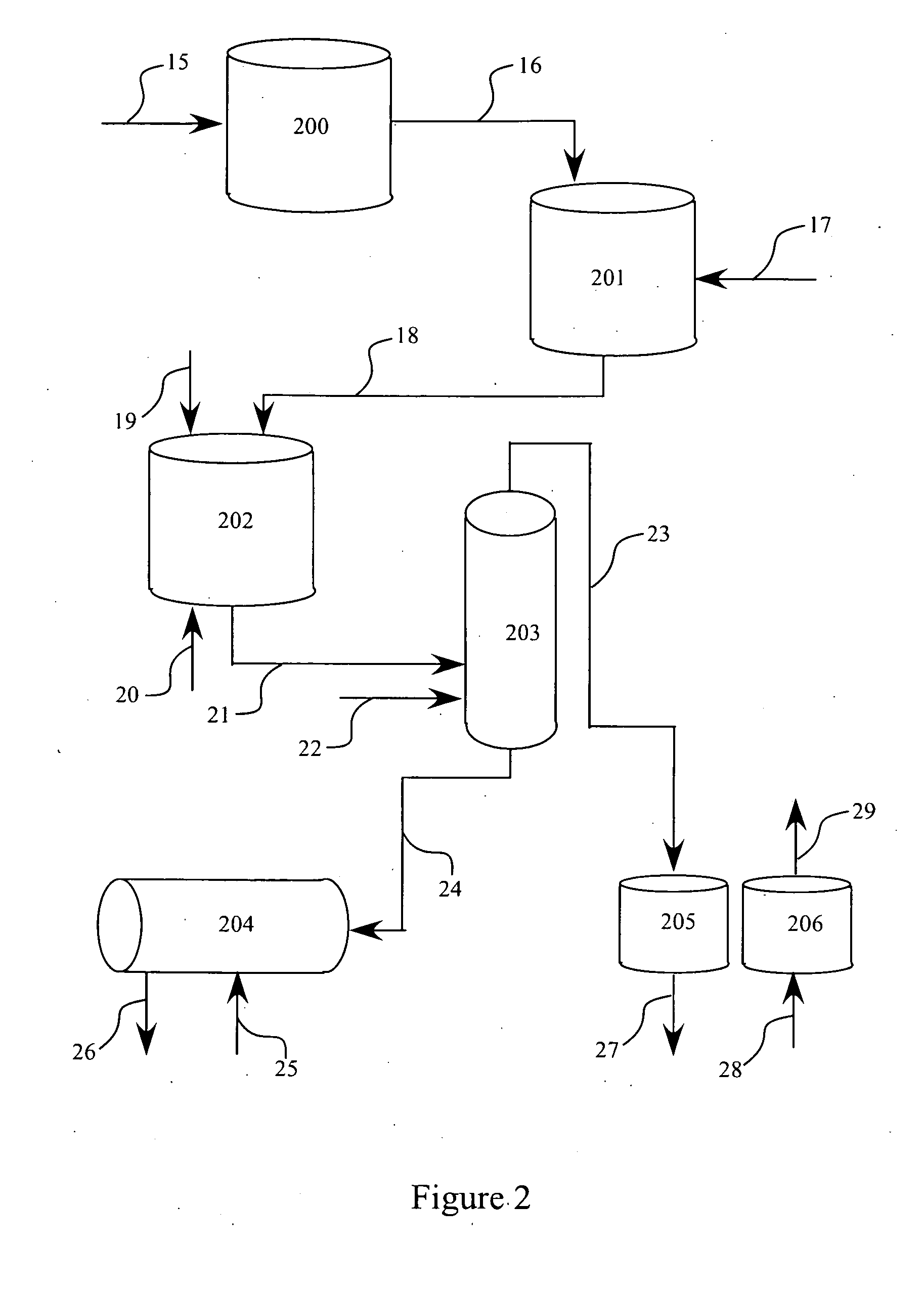

[0015]As noted, an embodiment of the present invention is directed to an integrated method and system for producing fuel from biomass. In particular, the method and systems described herein enable the efficient and effective utilization of waste heat from hydrocarbon synthesis of liquid transportation fuel components, in various thermal processes.

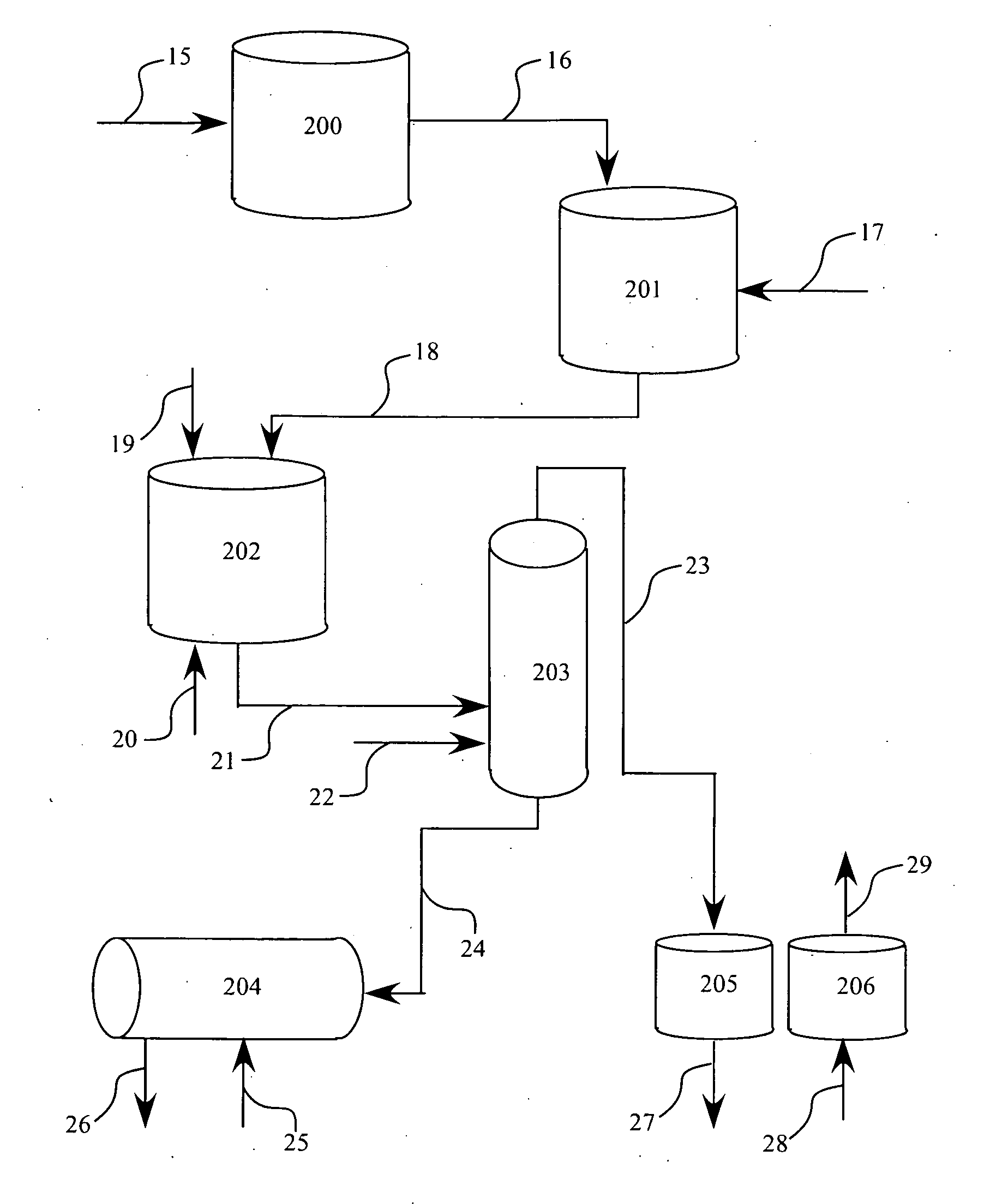

[0016]Referring now to FIG. 1, is shown a block flow diagram, schematically setting forth methods in accordance with embodiments of the invention. A biomass fermentate separation residue 10 is supplied to a step of providing 100 a feed comprising the biomass fermentate separation residue 10. As will be described in more detail later in this disclosure, the step of “providing”100 may comprise a pretreatment step such as pyrolysis, catalytic conversion, drying, concentrating, and / or charring (not specifically shown here). Provided feed 11 comprising biomass fermentate separation residue is recovered from providing step 100. The provided feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com