Elastic spunbonded nonwoven and elastic nonwoven fabric comprising the same

a technology of elastic nonwoven fabric and elastic nonwoven fabric, which is applied in the direction of weaving, conjugated synthetic polymer artificial filaments, weaving, etc., can solve the problems of affecting web uniformity, affecting the uniformity of webs, and troublesome bigger filament bundling, so as to facilitate the whole spunbonding process and reduce friction and polymer tackiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Perforated Hydroentangled Elastic Nonwoven Fabrics

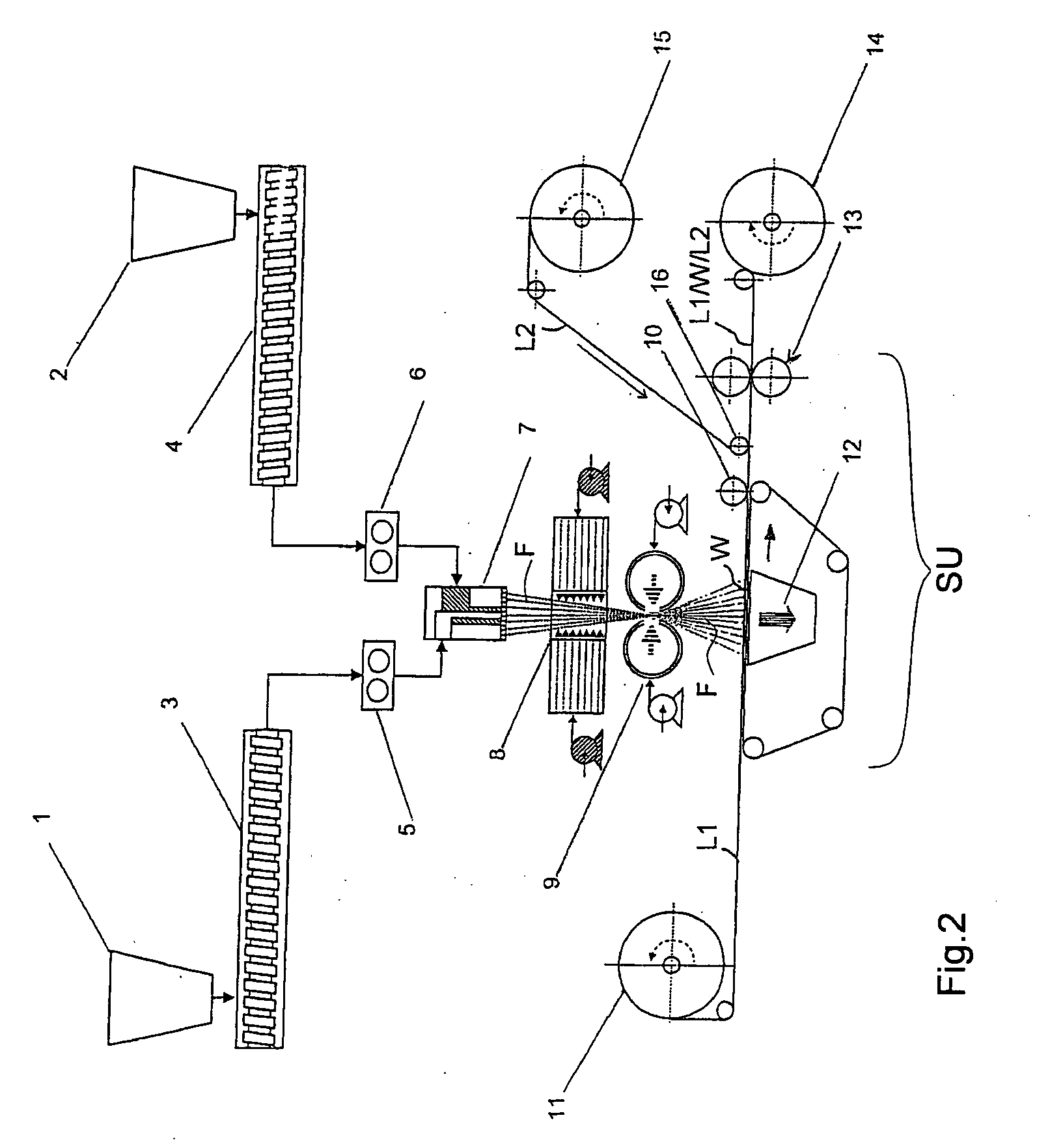

[0142]Different perforated composite nonwoven fabric (C / W, C / W / S and C / W / C) have been produced according to the manufacturing processes of FIGS. 3 and 4 (examples E-150-FP, E-151-FP, E-152-FP, E-153-FP, E-155-FP).

The compositions of these composite nonwoven fabrics are summarized in Table 7.

TABLE 7Perforated hydroentangled elastic nonwoven of the inventionElastictotalBottomspunbondedB.W.Layer,Layer WTop Layer,Examplesstructure(gsm)typegsm(see table 4)gsmtypegsmE-150-C / W60on line30E-7-830NONE0FPcardedPPE-151-C / W / S58on line20E-7-830Spunbonbded8FPcardedPPPPE-152-C / W / S110on line20E-7-1080Spunbonbded10FPcardedPPPPE-153-C / W / S90on line20E-7-660Spunbonbded10FPcardedPPPPE-155-C / W / C94on line20E-7-660Carded PP14FPcardedPPC: carded layerW: Elastic spunbonded layer of the inventionS: Spunbonded layerPP: Polypropylene

[0143]The outer carded layers (C) with low basis weight give textile appearance and soft touch to the final nonwoven fabric. This pr...

example

Elastic Spunbonded Nonwoven (W / M)

[0157]Samples of multilayer nonwoven (C / W / M / C) have been produced on a pilot plant, without bonding the layers together. Then the two outer carded layers were removed in order to keep only the elastic spunbonded (W) and meltblown (M) layers.

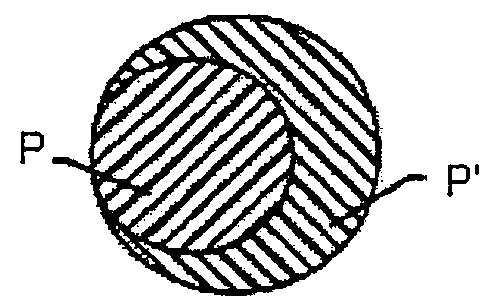

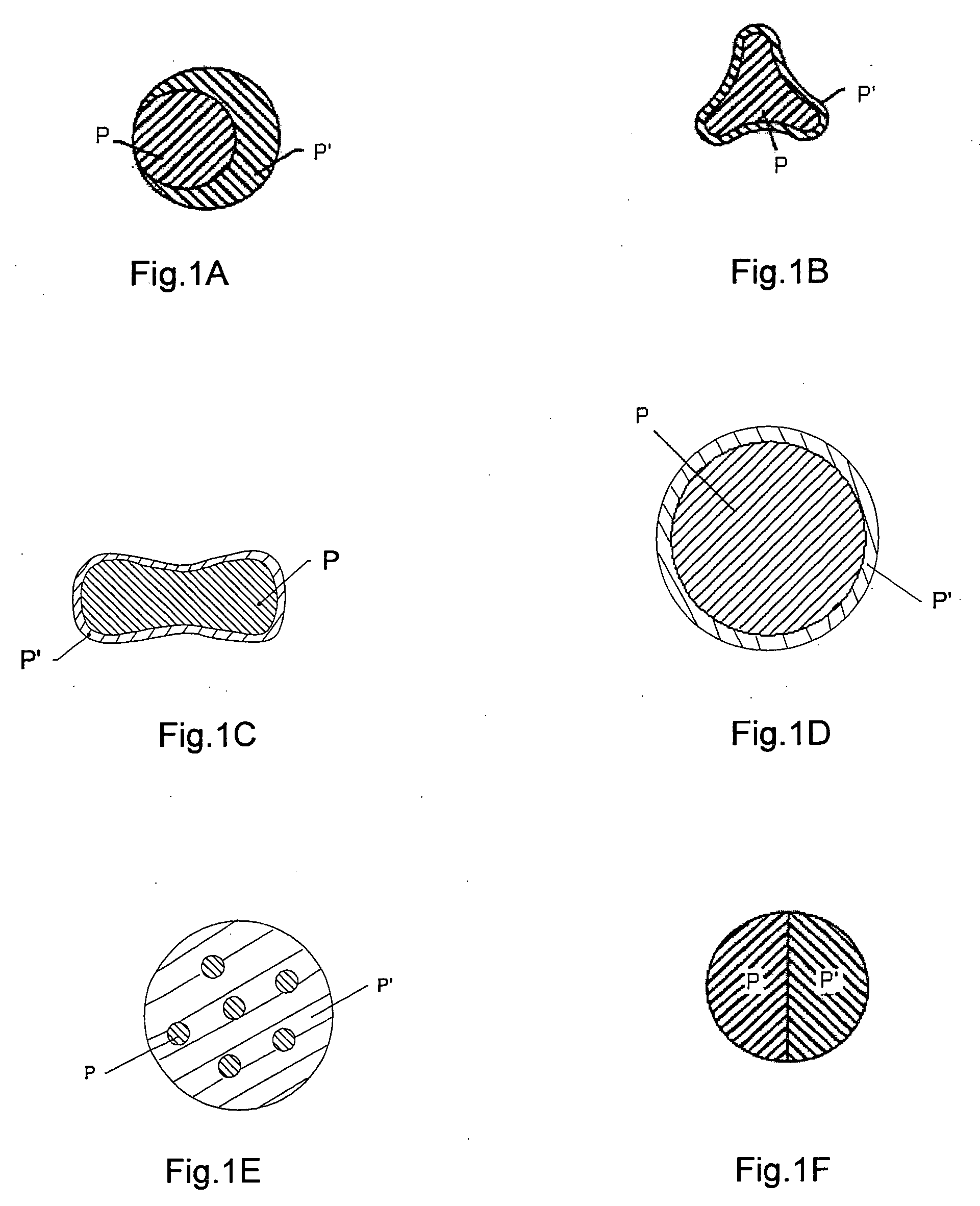

[0158]The elastic spunbonded layer W was made of bicomponent sheath / core filaments having the round cross-section of FIG. 1D. The core of the filaments was made (first polymeric component P) of a blend VM2125 (70 wt %) and VM6100 (30 wt %). The outer sheath of the filaments was made of VM 2125 (second polymeric component P′). The weight of the core was 90% of the total basis weight, and the weight of the sheath was 10% of the total basis weight. The basis weight of the elastic spunbonded layer (W) was 54 gsm.

[0159]In this example the material used for the elastic meltblown layer (M) was VM 2320. The basis weight of the meltblown layer (M) was 10 gsm. The elastic properties of the elastic spunbonded nonwoven (W / M) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com