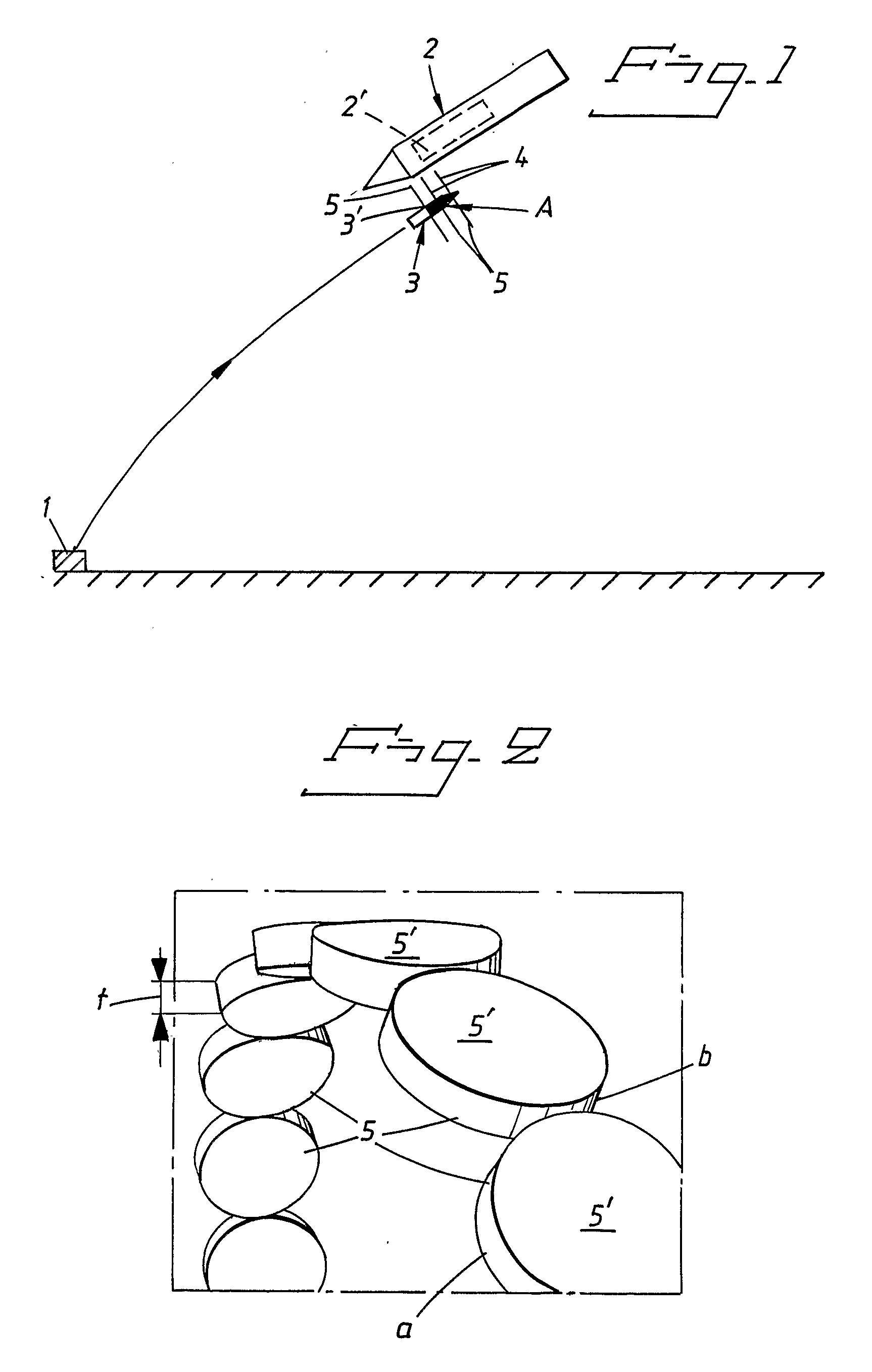

[0029]The basic concept behind the present invention is thus to configure the components forming part of the own action element so that the splinter bodies shaped by the splinter shell of the own action element acquires, compared with their own

mass, a large surface facing in the direction of an incoming enemy missile, shell, bomb, craft, etc. and a correspondingly small thickness in the same direction, which means that that side of the splinter bodies, hereinafter referred to as the broadside, which is directed towards and hits the incoming enemy missile, etc., comprising the above and below named first external explosive charge, shall have the shape of laminae, plates, discs, ellipsoids or equivalent. The invention further includes an assurance that these splinters of laminar, plate-like,

ellipsoid or other equivalent configuration shall hit the intended target at a sufficiently high speed with their own broadside first and, in so doing, transfer a sufficient kinetic impulse to the explosive charge of the first incoming enemy missile over a sufficient area to initiate the explosive to detonation. This specific configuration of the splinter bodies thus offers a possibility of hitting the target with splinter bodies which, in the event of a hit, provided that they have thus initially been given a sufficiently high speed and despite their limited own

mass, transfer a sufficient quantity of kinetic impulse over a sufficient area of explosive to ensure an

initiation of the explosive charge forming part of the combated missile. By impulse is here meant, in somewhat simplified terms, a change in the

momentum, i.e. the product of mass times speed in a certain direction, of an object.

[0030]Since the above-indicated shape of the splinter bodies configured according to the invention has been able to be given a large surface compared with their own mass, the splinter-forming shell of the action element has been able to be made thinner and hence lighter, whilst, at the same time, a correspondingly lesser amount of detonating charge of explosive inside the splinter-forming shell will be needed to give the splinter bodies released therefrom upon detonation of the explosive charge a sufficiently high initial speed in the direction of the target, i.e. of the foreign missile. This general basic notion thus offers the prospect of markedly reducing the size of the action element which is necessary to combat foreign incoming explosive-charged missiles, and hence the size of the entire

weapon system in question and the costs of the same.

[0031]In order for the laminar, plate-shaped or ellipsoidal, etc. splinters to produce the effect outlined above, it is required, however, that, firstly, they maintain their original shape until hitting the target and, secondly, they actually hit the target with their broadside first.

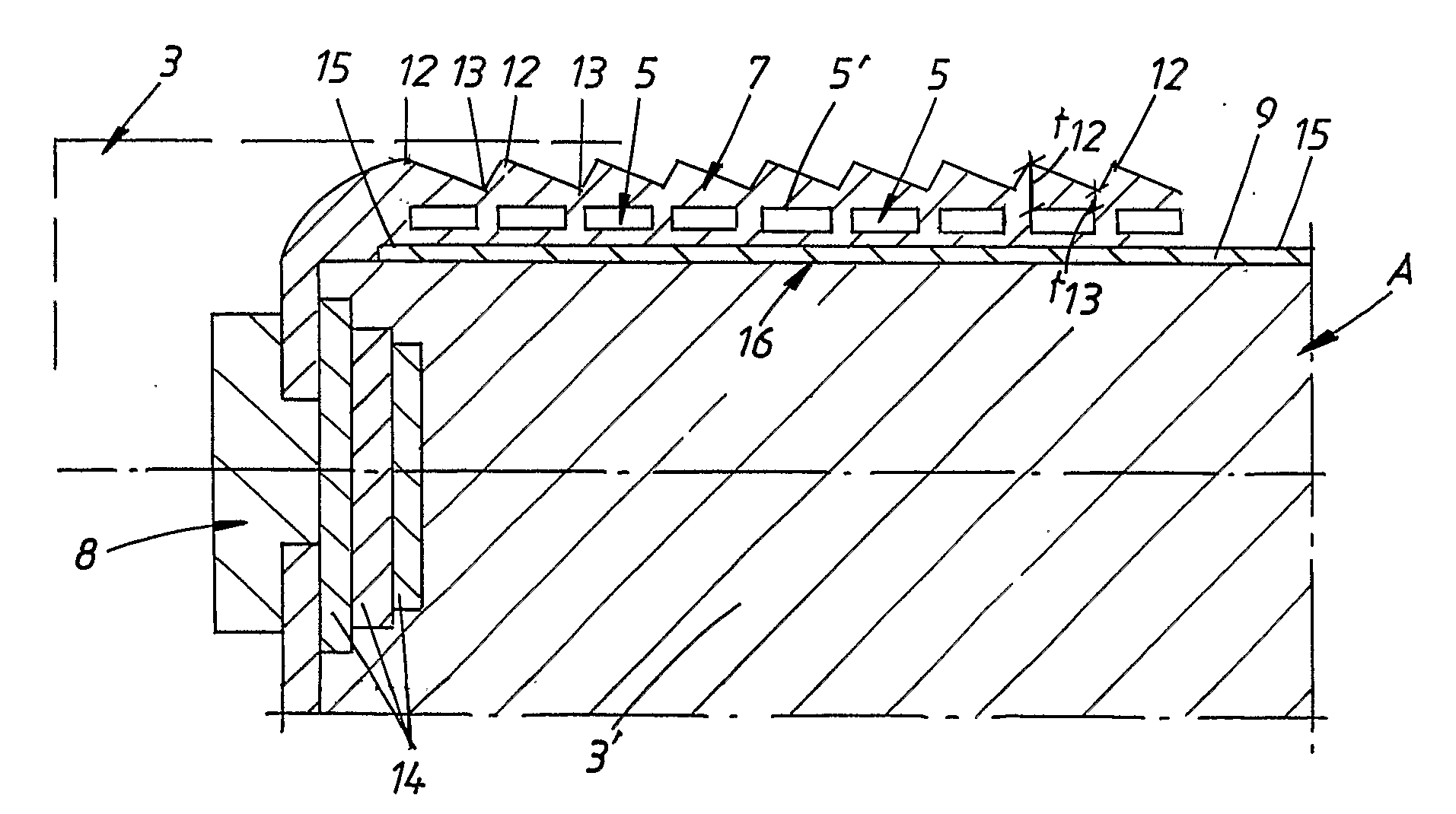

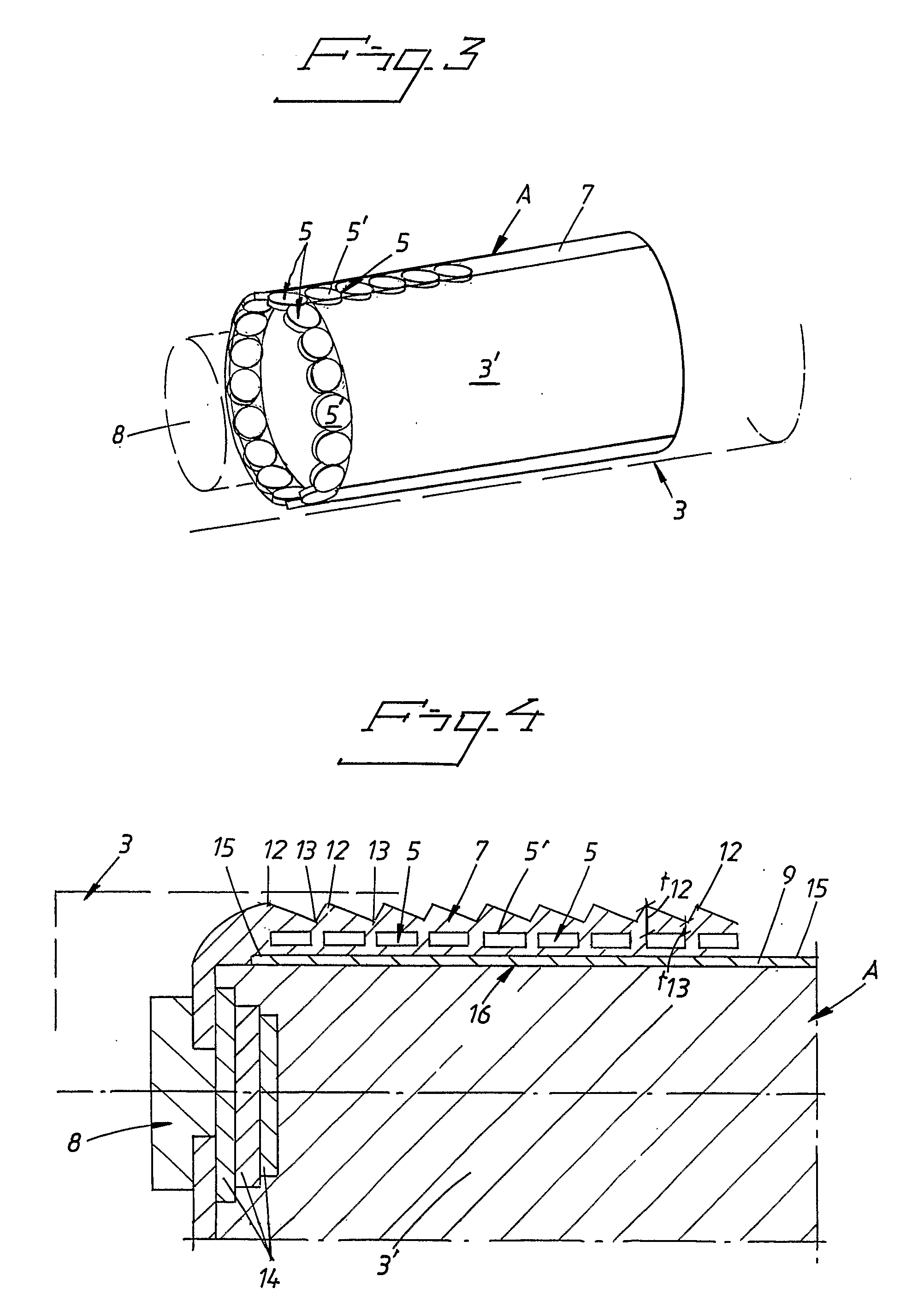

[0032]The first of the above-specified conditions means that the splinter shell from which the splinters are released, upon detonation of the explosive charge disposed inside the splinter shell, is fragmented only at precisely those points and along those parting lines which were originally presumed, and this can be ensured by means of weaker sections, for example in the form of material thinnings, at the said points and along the desired parting lines, built from the outset into the splinter shell. A better solution to the same problem is, however, to produce the splinter shell by

powder metallurgy methods, pre-produced splinter bodies being inserted into a matrix, produced by

powder-

metallurgy methods, which separates the splinter bodies one from another and from the explosive charge and which, by virtue of the fact that the matrix, upon detonation of the explosive, surrounds the splinter bodies, gives these a gentle acceleration, which prevents the splinter bodies from fragmenting and ensures that these are accelerated in the desired direction, namely in the direction of the incoming enemy missile, etc. This process for the production of the splinter shells therefore has the

advantage that, by producing the splinter bodies separately, it is possible to give them the most favourable configuration for each individual case and, moreover, to give them a substantially higher strength than the matrix material which initially holds the splinter shell together. Consequently, it is thus possible effectively to prevent an undesirable fragmentation of the splinter bodies and to ensure that these, when they are released from the splinter shell and begin their flight towards the target, acquire precisely that configuration which is designed for the purpose.

[0033]The division of the splinter shell into splinter bodies of a desired shape, irrespective of whether the splinter shell is produced by

powder-metallurgical methods or not, might also be to some extent ensured by specific counterstaying elements disposed on the outside of the splinter shell along desired rupture lines between the desired splinter bodies.

[0034]In order to reinforce and further ensure the division of the splinter shell into splinter bodies of desired size and shape along predetermined rupture lines or along the space between prefabricated splinter bodies baked into a powder-metallurgical matrix, and in order, at the same time, to prevent an undesirable further fragmentation of the splinter bodies, the inner side of the splinter shell can be provided with

shock wave traps in the form of one or more

layers of linings of material which exhibits strongly different acoustic properties from the rest of the splinter shell. As examples of materials which can be used as such

shock wave traps, plastics of different

hardness and density can be cited.

Login to View More

Login to View More  Login to View More

Login to View More