Electrochemical cell with improved internal contact

a technology of internal contact and electrochemical cells, which is applied in the direction of cell components, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as anode disconnects, and achieve the effects of improving contact reliability, reliable pressure contact, and increasing tolerance of variability in manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

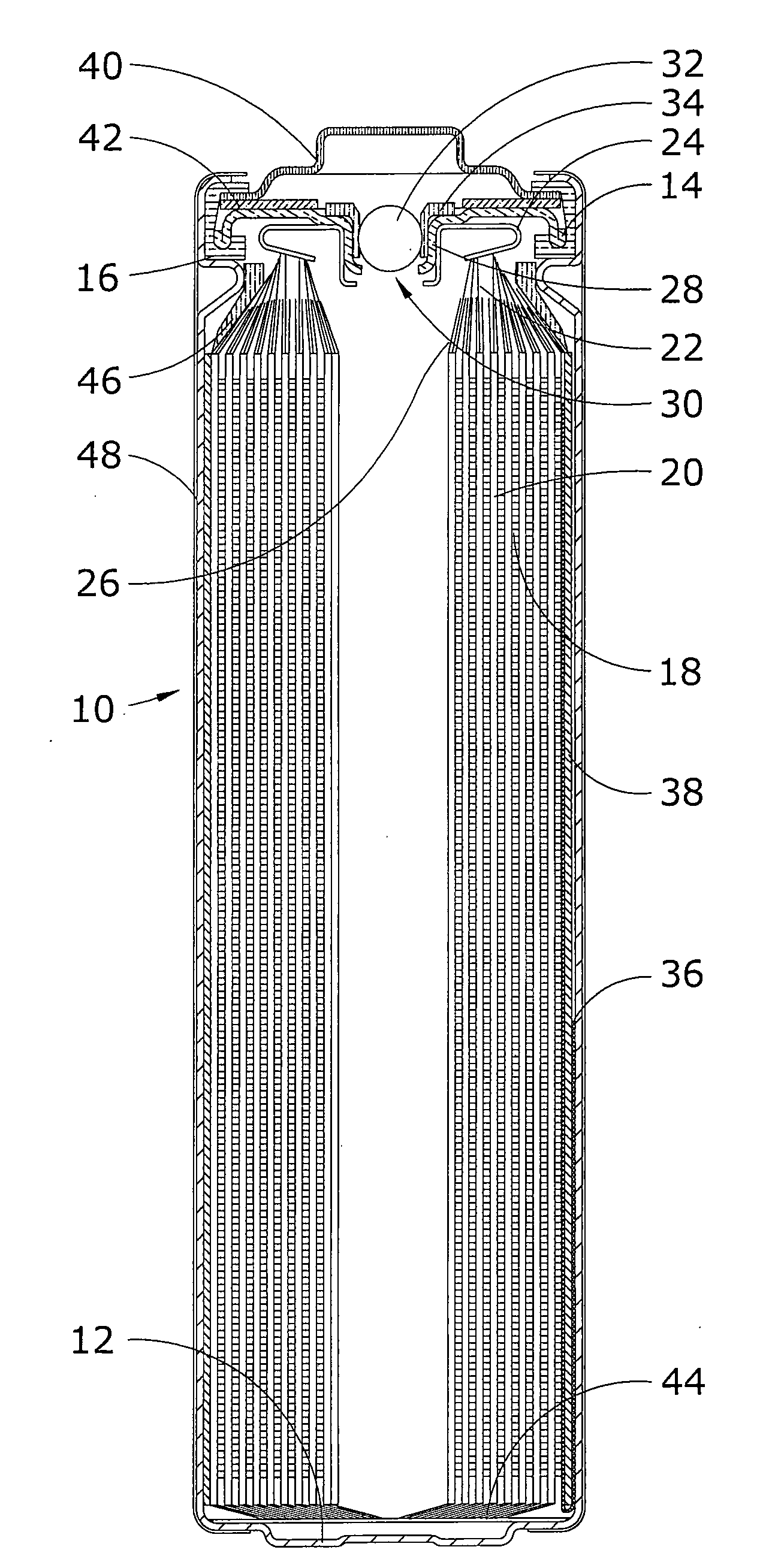

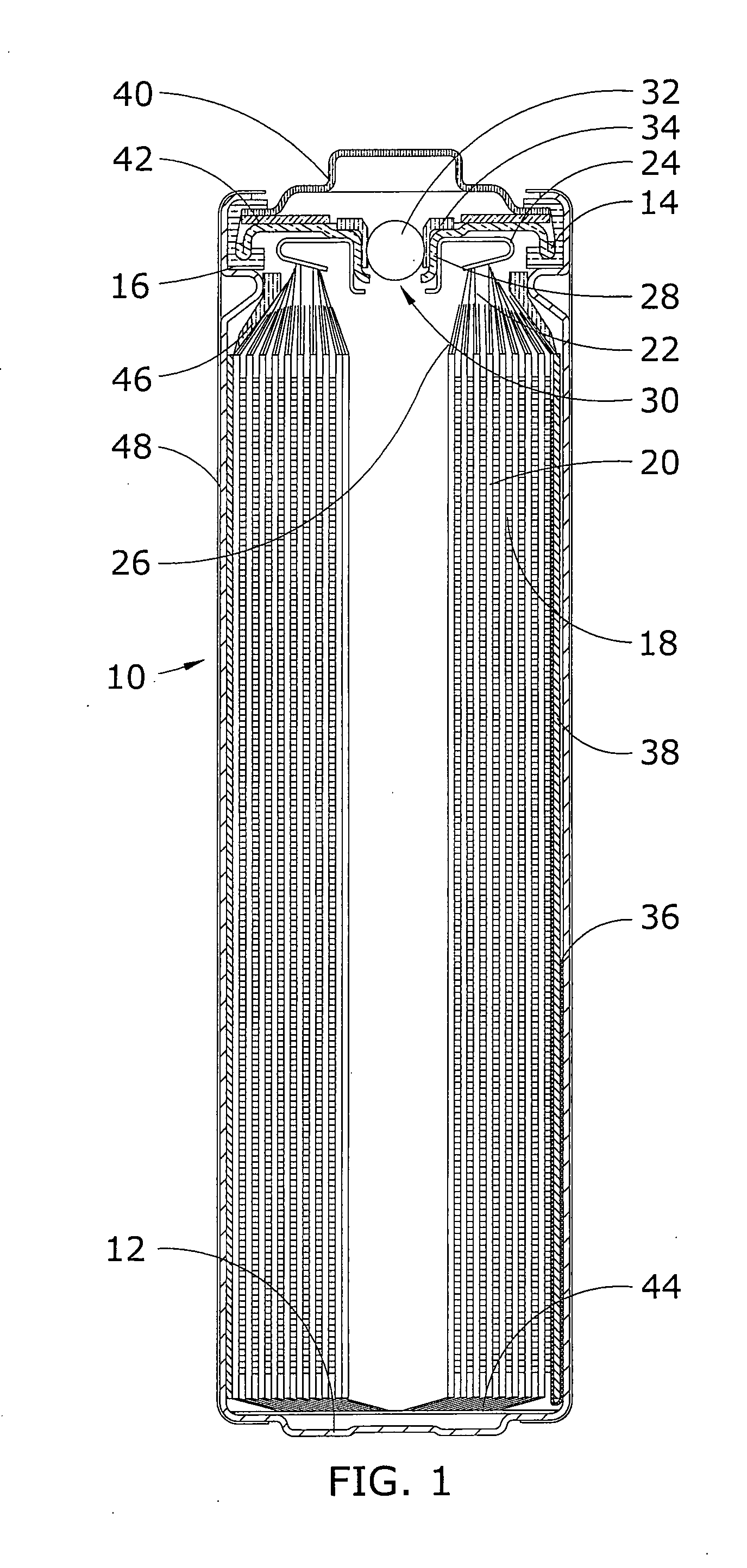

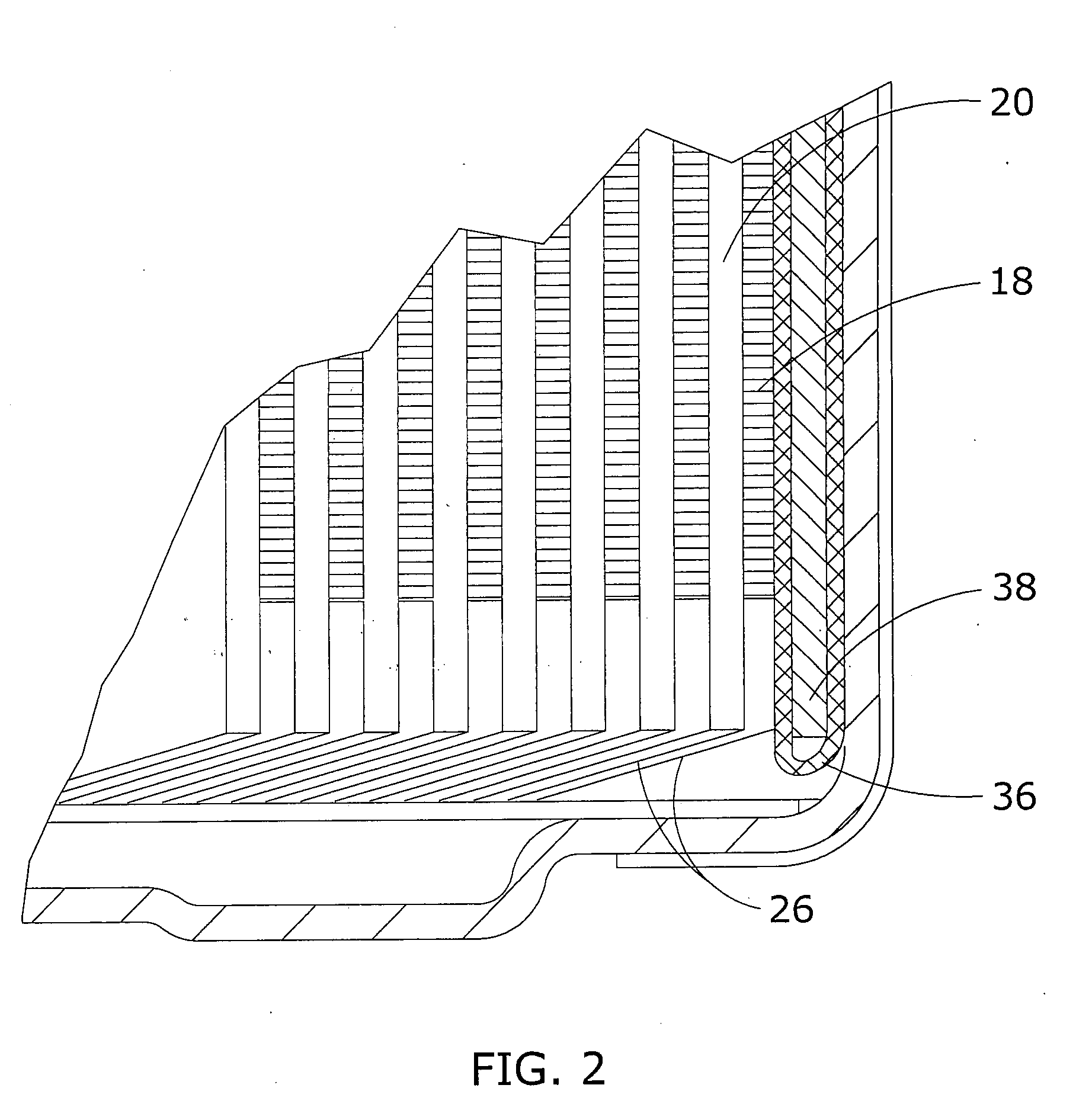

[0107]Computer modeling was used to evaluate several negative electrode lead designs suitable for use in FR6 and FR03 cells with electrode assemblies similar to that illustrated in FIG. 1. The model was used to determine the spring force that could be exerted by the terminal end of a lead similar to the negative electrode lead in FIGS. 1 and 2. The spring force determined should approximate the amount of force exerted by the terminal portion of the lead against the inside surface of the side wall of the can.

[0108]The model used the following material properties for 0.051 mm (0.002 inch) thick nickel plated, cold rolled steel strip for the leads: Young's modulus=2.07×108 Pa (3.00×107 lb. / in2), Poisson's ratio=0.285 and initial yield strength=251,000 Pa (36,400 lb. / in2).

[0109]Three different shapes were evaluated for the terminal portion of the lead (the portion adjacent to the external surface of the electrode assembly, above the bend around the bottom of the electrode assembly, prio...

example 2

[0119]Ten lots of FR6 cells, similar to cell 10 in FIGS. 1 and 2, were made to evaluate cell characteristics and performance. Each cell in Lots 1 and 2 had a 0.0254 mm (0.001 inch) thick strip of polyethylene film wrapped around the electrode assembly circumference. The average electrode assembly outside diameter (including the strip of polyethylene film was 13.06 mm (0.514 inch). Each cell in Lots 3-10 had no outer wrap of polyethylene film, and the average outside diameter of the electrode assembly was 12.95 mm (0.510 inch). In all lots the average inside diameter of the can was 13.41 mm (0.528 inch). In all lots the negative electrode lead was made from a thin strip of conductive metal 4.75 mm (0.187 inch) wide, cut to a length of 55.9 mm (2.20 inch). One end of the lead was attached to the lithium negative electrode near its outer end, so that the terminal end of the lead protruded from the bottom end of the assembled electrode assembly, where it was bent outward and then upward...

example 3

[0122]Eight lots of FR6 cells, similar to cell 10 shown in FIGS. 1 and 2, were constructed to determine average service life of the cells. The cells of each lot had an interfacial, theoretical A / C input capacity ratio of 0.92.

[0123]Each of the Control Lot 1 and Lots 11-14 were identical with exception to the negative electrode lead as explained hereinbelow. The negative electrode consisted of lithium alloy foil having an aluminum content of about 0.5 weight %. Cells of Control Lot 1 included a nickel plated cold rolled steel negative electrode lead welded to 96% of the width of the lithium foil and had an overall length of 55.80 mm (2.200 inches). Cells of Lot 11 had an anode lead directly connected to 50% of the width of the lithium foil and an overall length of 37.97 mm (1.495 inches). Cells of Lot 12 had a nickel plated cold rolled steel negative electrode lead that extended 25% of the width of the lithium foil and an overall length of 28.22 mm (1.111 inches). Cells of Lot 13 had...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com