System and Distribution Tank for Low-Energy Network

a low-energy network and distribution tank technology, applied in the direction of heat pumps, heating types, lighting and heating apparatus, etc., can solve the problems of significant consumption of heating energy in properties, difficulty in placing horizontal pipes in parks, and significant loose ground on top of rocks, so as to facilitate the implementation of the system, reduce the thickness of the isolation of the first main pipe, and reduce the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

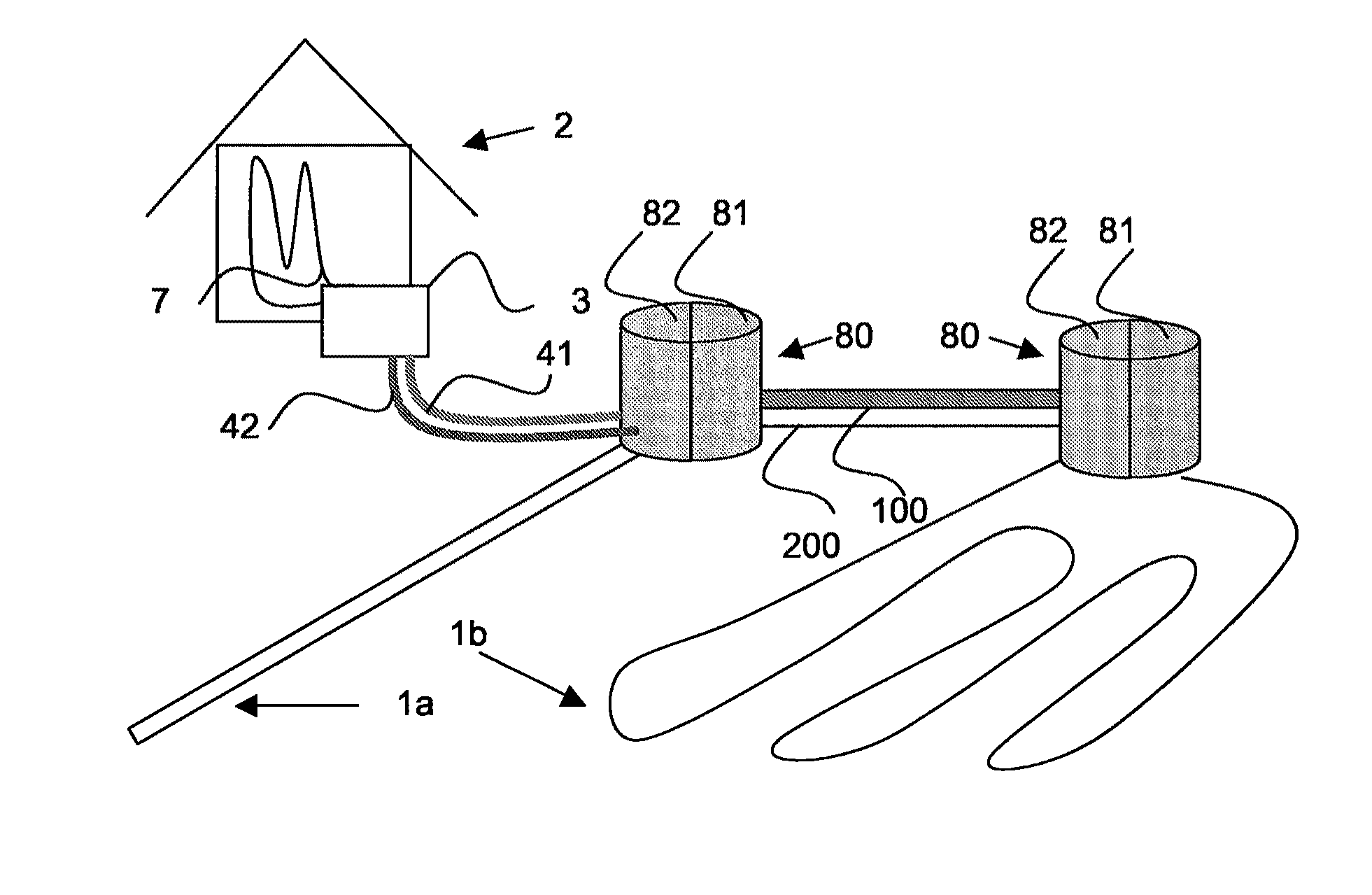

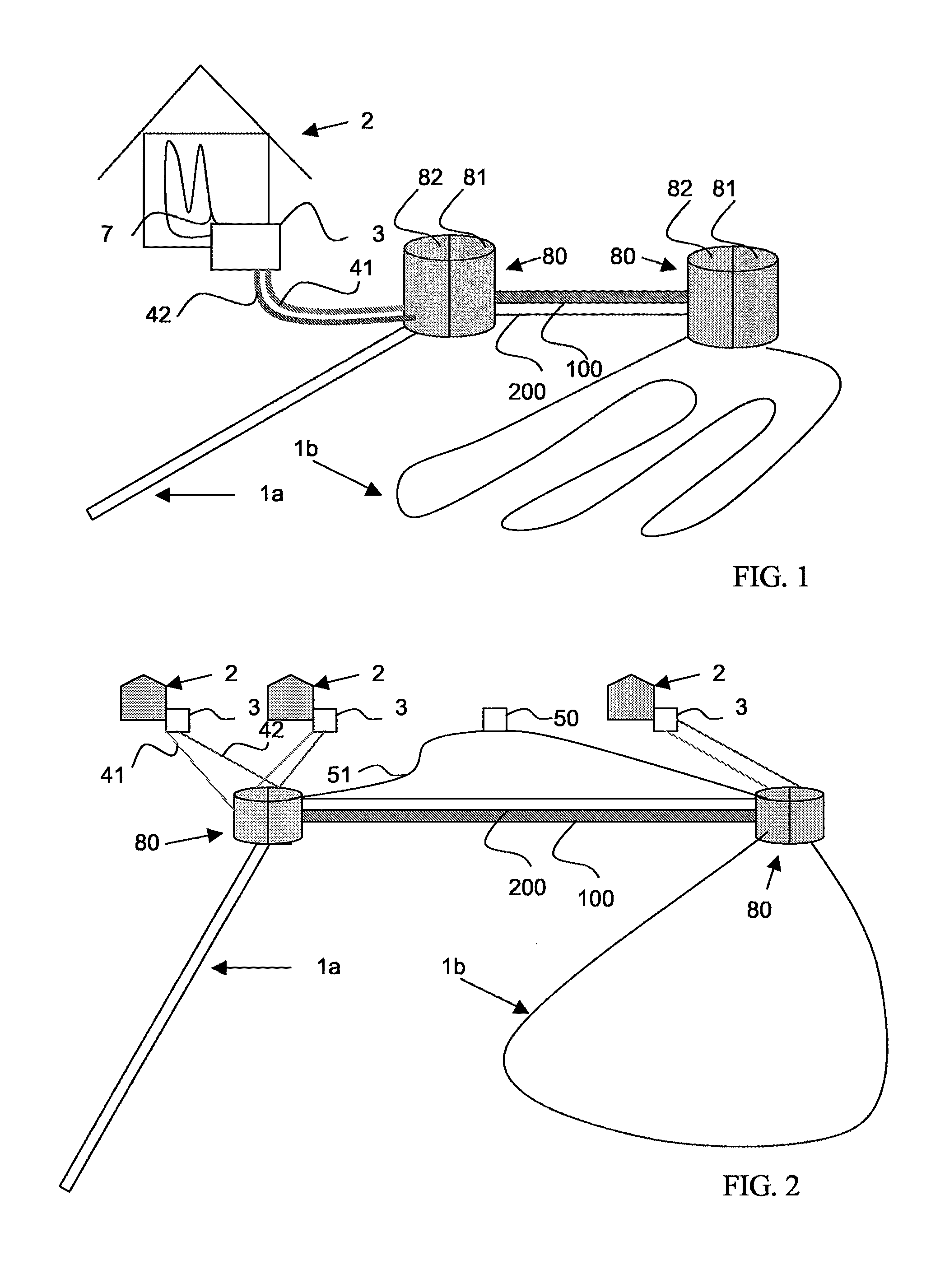

[0036]FIG. 2 shows the system according to the present invention. The terminals 3 of two houses 2 are connected to the distribution tank 80 located on the left, the terminal 3 of one house 2 being connected to the distribution tank located on the right. The flow in the collector pipes connected to the distribution tanks 80 is controlled with a control system 50. In the case of heating, wherein for instance the terminal 3 starts and when the transfer liquid of collector circuit 1b is warmer than the liquid of collector circuit 1a, the control system is able to restrict the flow of collector circuit 1a and increase the flow of collector circuit 1b such that the terminal is able to receive transfer liquid that is as warm as is preferable in view of performance. In the case of cooling, the situation is naturally reversed.

[0037]The control system 50 includes preset data for each collector circuit connected thereto and is able to use the data to restrict or increase the flow of each colle...

third embodiment

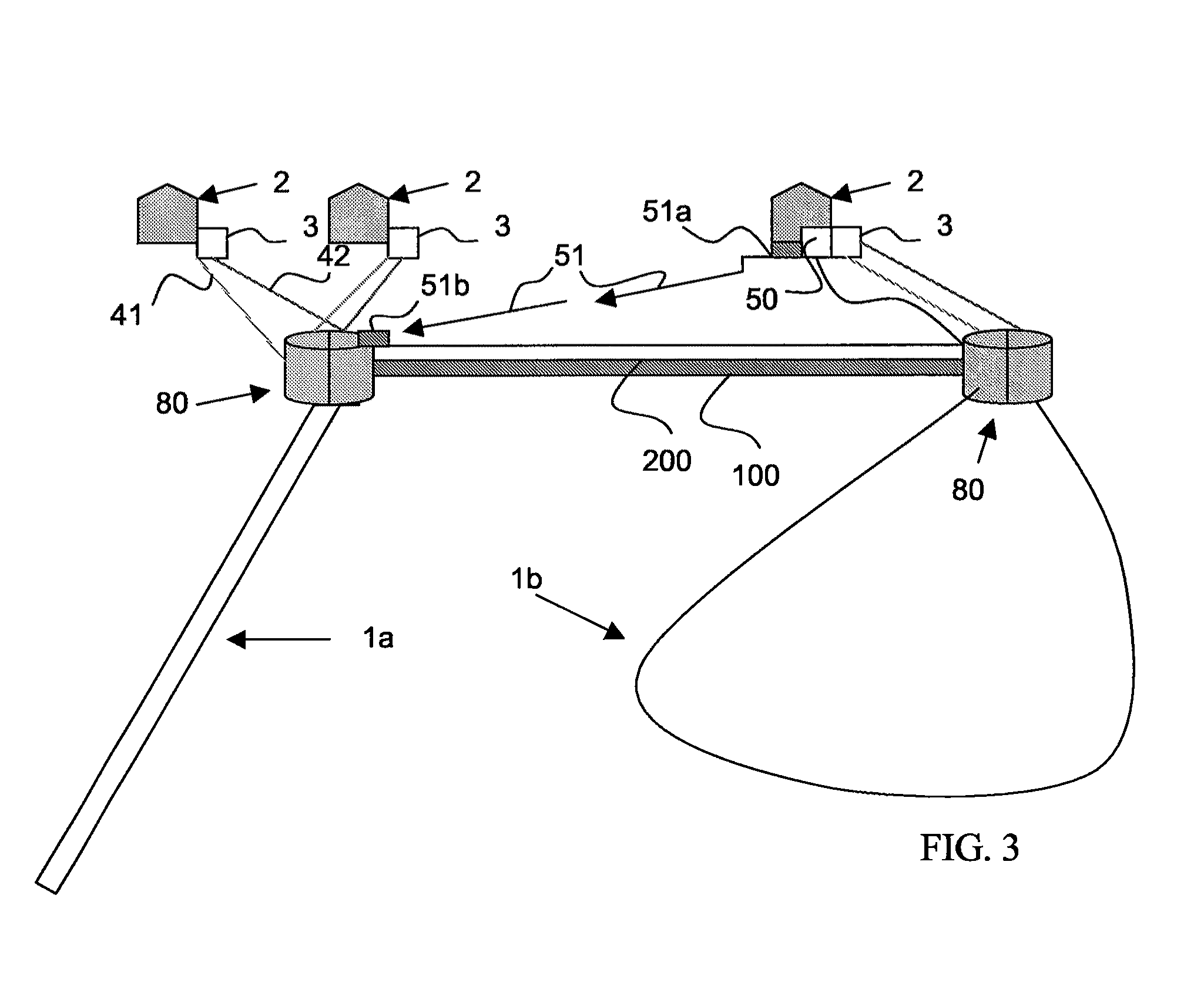

[0038]FIG. 3 shows the system according to the present invention, wherein the control system 50 is connected to one distribution tank by a wired connection and to another distribution tank 80 by a wireless connection. In the case of the wireless connection, the control system 50 and the distribution tank are provided with appropriate transmission and reception means 51a, 51b. The control system 50 is preferably connected to an information network, such as the Internet. This enables remote monitoring and control of the system.

[0039]FIG. 4 shows a front view of an embodiment of the distribution tank according to the present invention. The distribution tank 80 comprises a first reservoir 81 and a second reservoir 82, of which the first reservoir 81 is intended to receive and transfer heated transfer liquid, the second reservoir 82 being intended to receive and transfer cooled transfer liquid. The reservoirs comprise main pipe receiving means 110, 120 for receiving the main pipes 100, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com