Double DX Hydronic System

a hydronic system and double dx technology, applied in the direction of sustainable buildings, heating types, lighting and heating apparatus, etc., can solve the problems of increasing the power draw of the compressor, reducing reducing the power consumption of the compressor, so as to maximize the overall system operational efficiency, avoid water pumping, and minimize the power consumption required to operate the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The following detailed description is of the best presently contemplated mode of carrying out the subject matter disclosed herein. The description is not intended in a limiting sense, and is made solely for the purpose of illustrating the general principles of this subject matter. The various features and advantages of the present disclosure may be more readily understood with reference to the following detailed description taken in conjunction with the accompanying drawings.

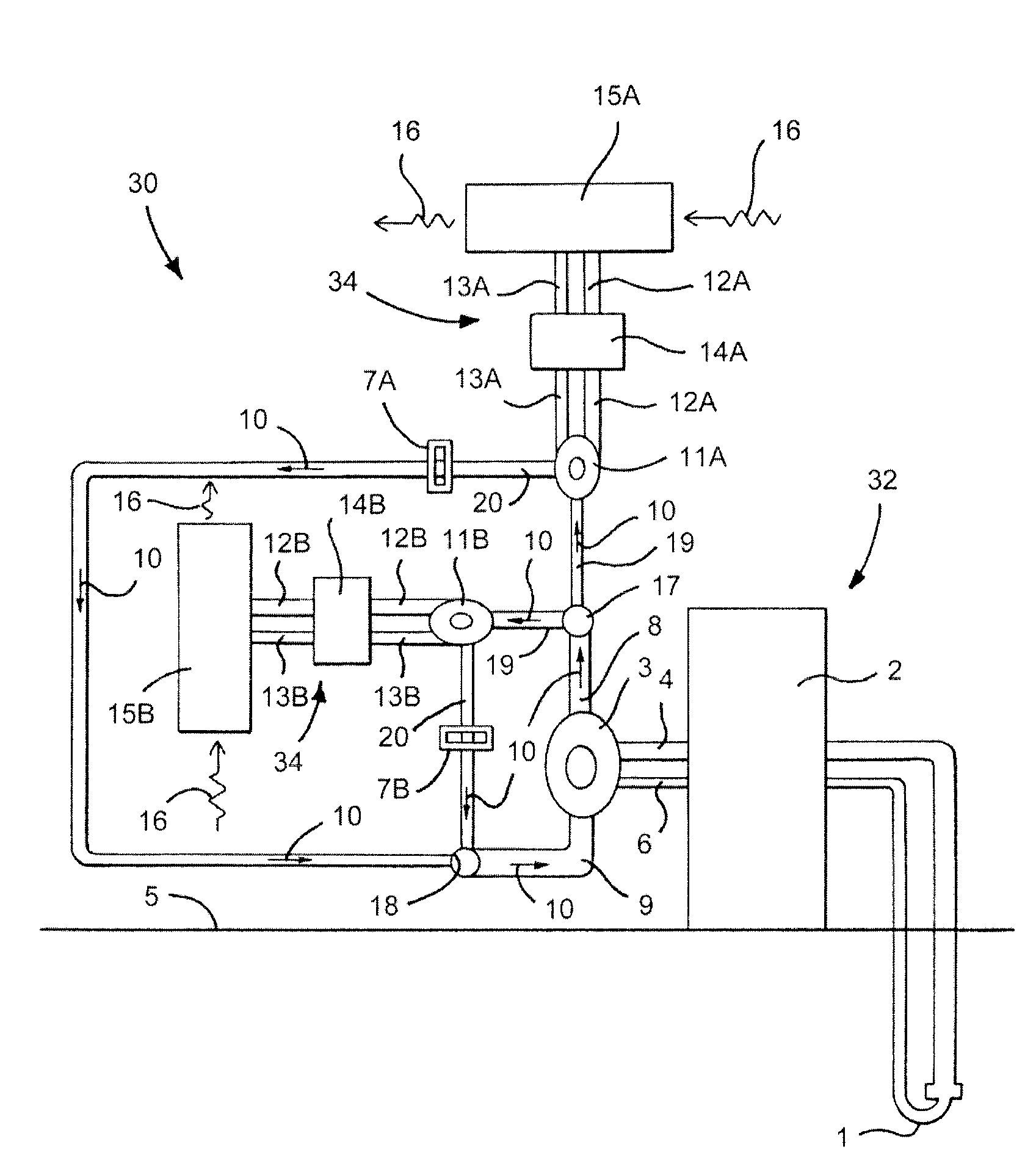

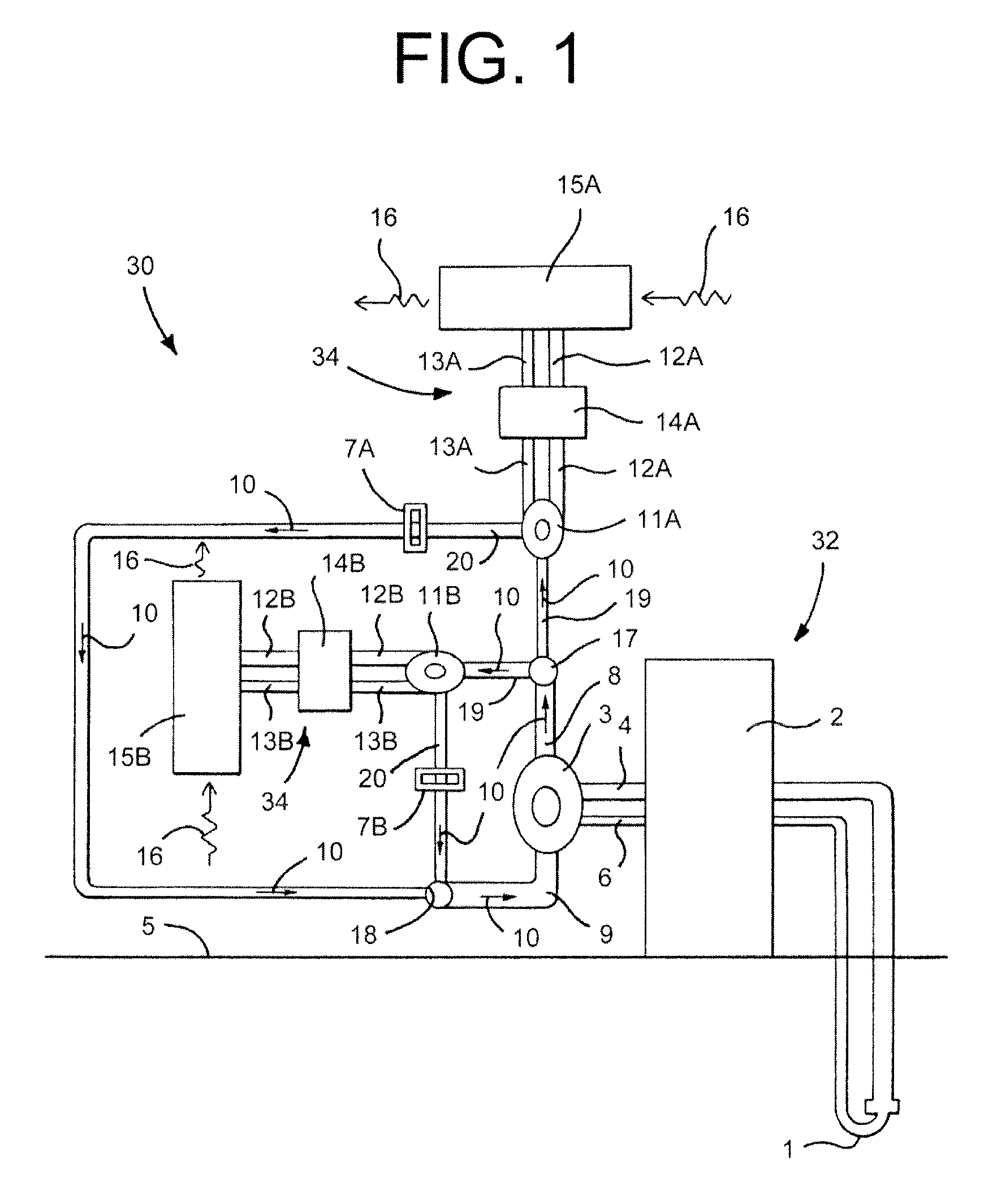

[0029]FIG. 1 shows a double DX hydronic system 30 capable of simultaneously heating and cooling separate control media, such as interior air (not shown). The system 30 may generally include a primary DX sub-system 32 and at least two secondary DX sub-systems 34, with unique additional features, as more fully described herein.

[0030]The primary DX sub-system 32 may include a primary heat exchanger 1 located below a surface 5 of the ground or water. Accordingly, the primary heat exchanger is alternatively ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com