Acoustic load mitigator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

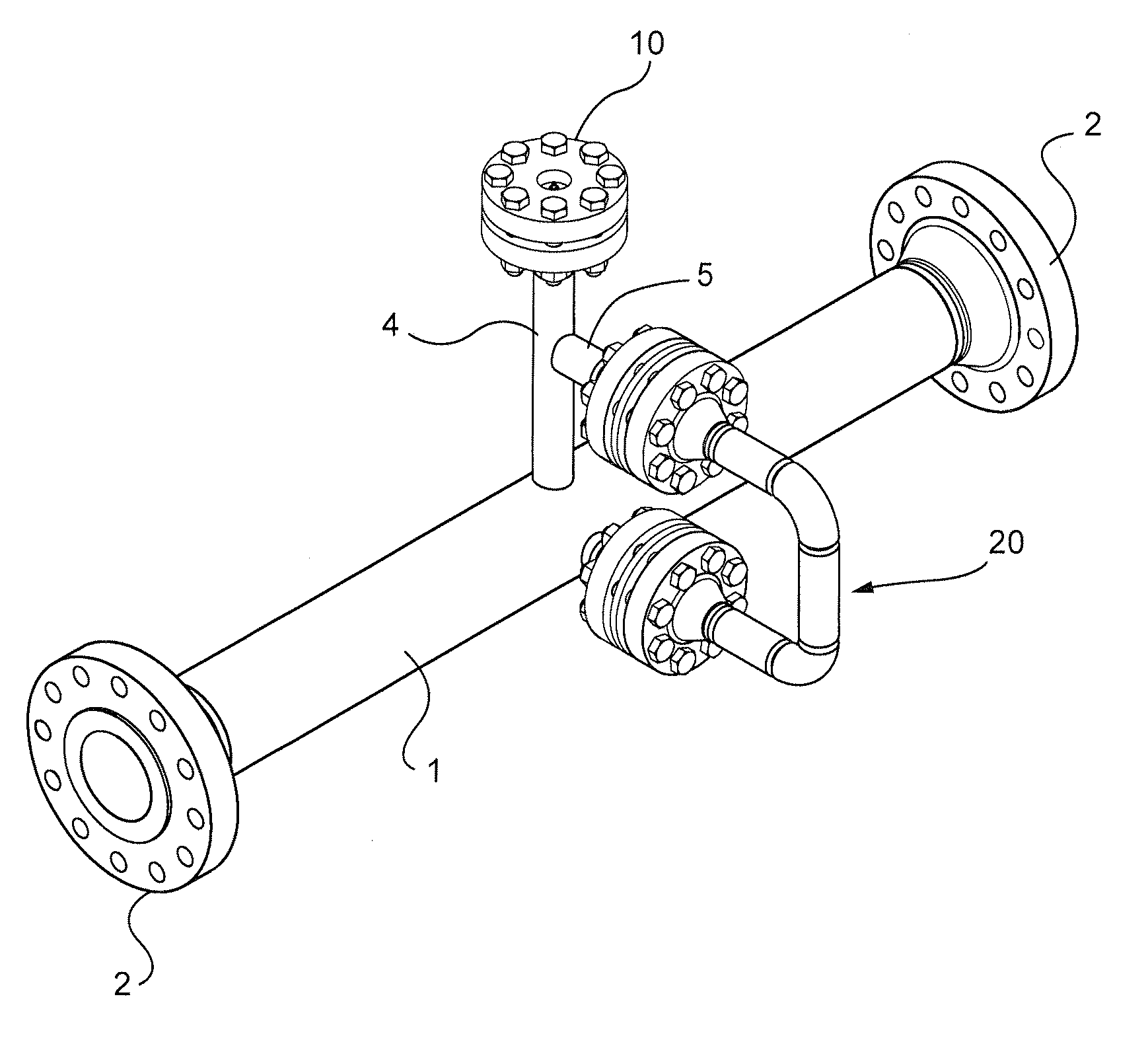

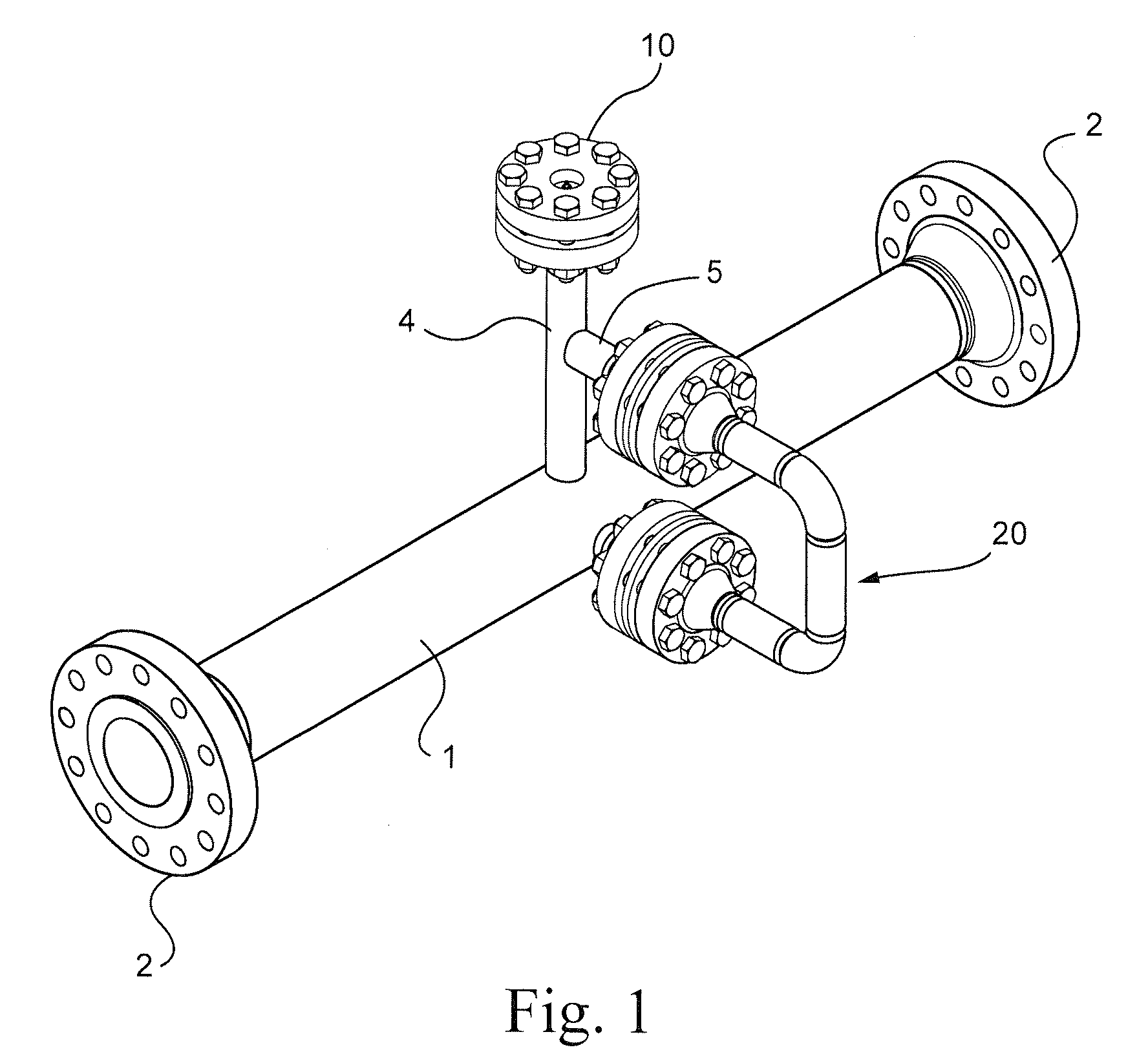

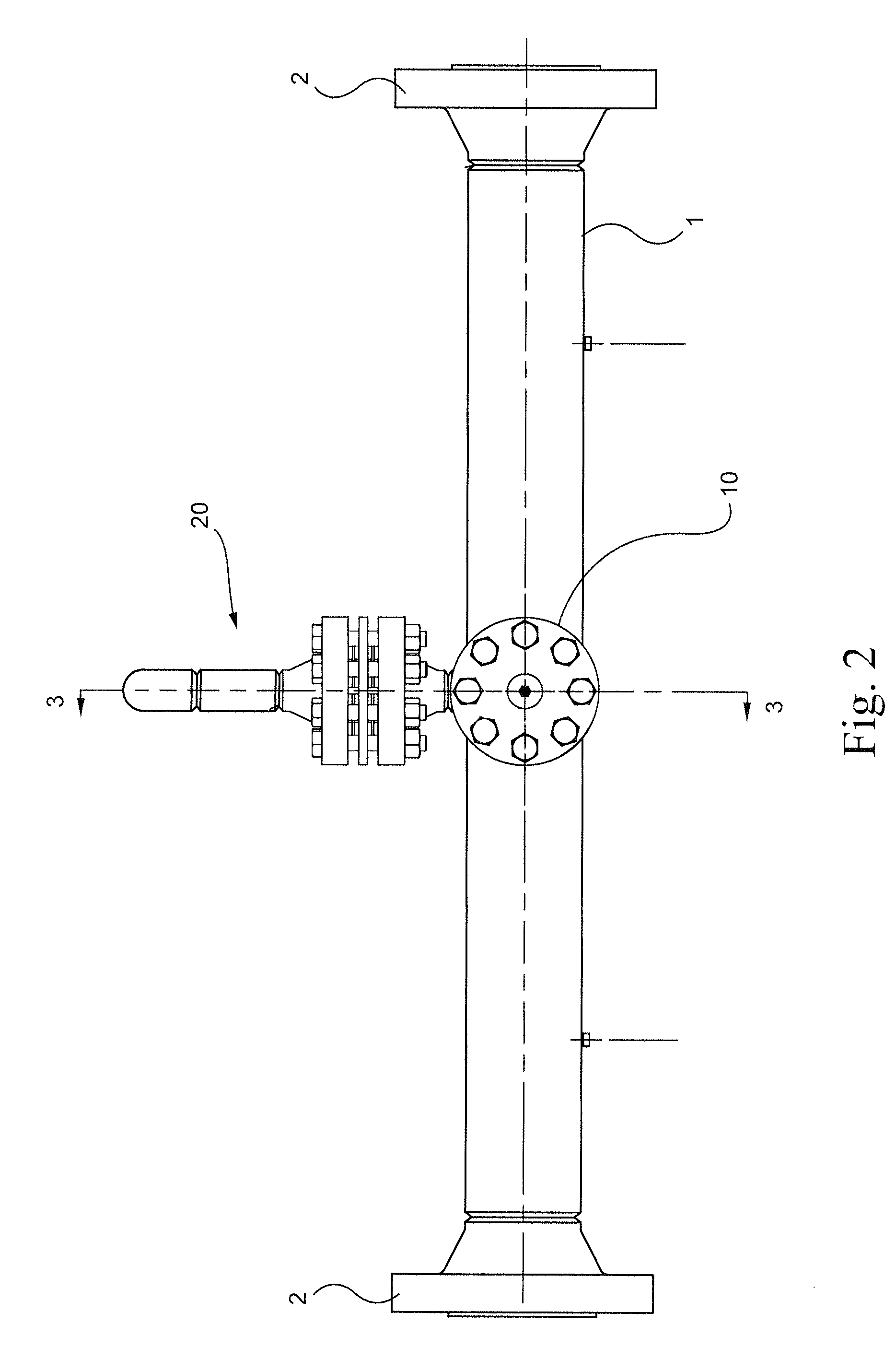

[0016]Referring to FIGS. 1-3, a steam line pipe 1, for example, in a nuclear power generating station such as a boiling water reactor (BWR) comprises pipe flanges 2 at opposite ends for connection of the steam line pipe 1 to a steam delivery line. A pressure sensor 18 may be provided in the steam line pipe 1 to measure a pressure of steam carried by the steam line.

[0017]A standoff pipe 4 is connected to a first outlet 21 of the steam line pipe 1 for mounting of a safety relief valve (not shown) to a pipe flange 10 provided on the standoff pipe 4. A pressure sensor 23 is provided on the pipe flange 10 to measure pressure of the steam in the standoff pipe 4. A bypass pipe 20 is connected to the steam line pipe 1 and the standoff pipe 4.

[0018]Referring to FIG. 3, the bypass pipe 20 is connected at one end to the steam line pipe 1 at a second outlet 24 of the steam line pipe 1 by a pipe base 3. The bypass pipe 20 is connected at the other end to the inlet 22 of the standoff pipe 4 by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com