Heat sink device

a heat sink and heat sink technology, applied in the field of heat radiators, can solve the problems of increasing material cost, affecting heat radiation performance, cracking of insulating substrates, etc., and achieve the effects of preventing cracking, excellent thermal conductivity, and improving heat radiation performance for radiating hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

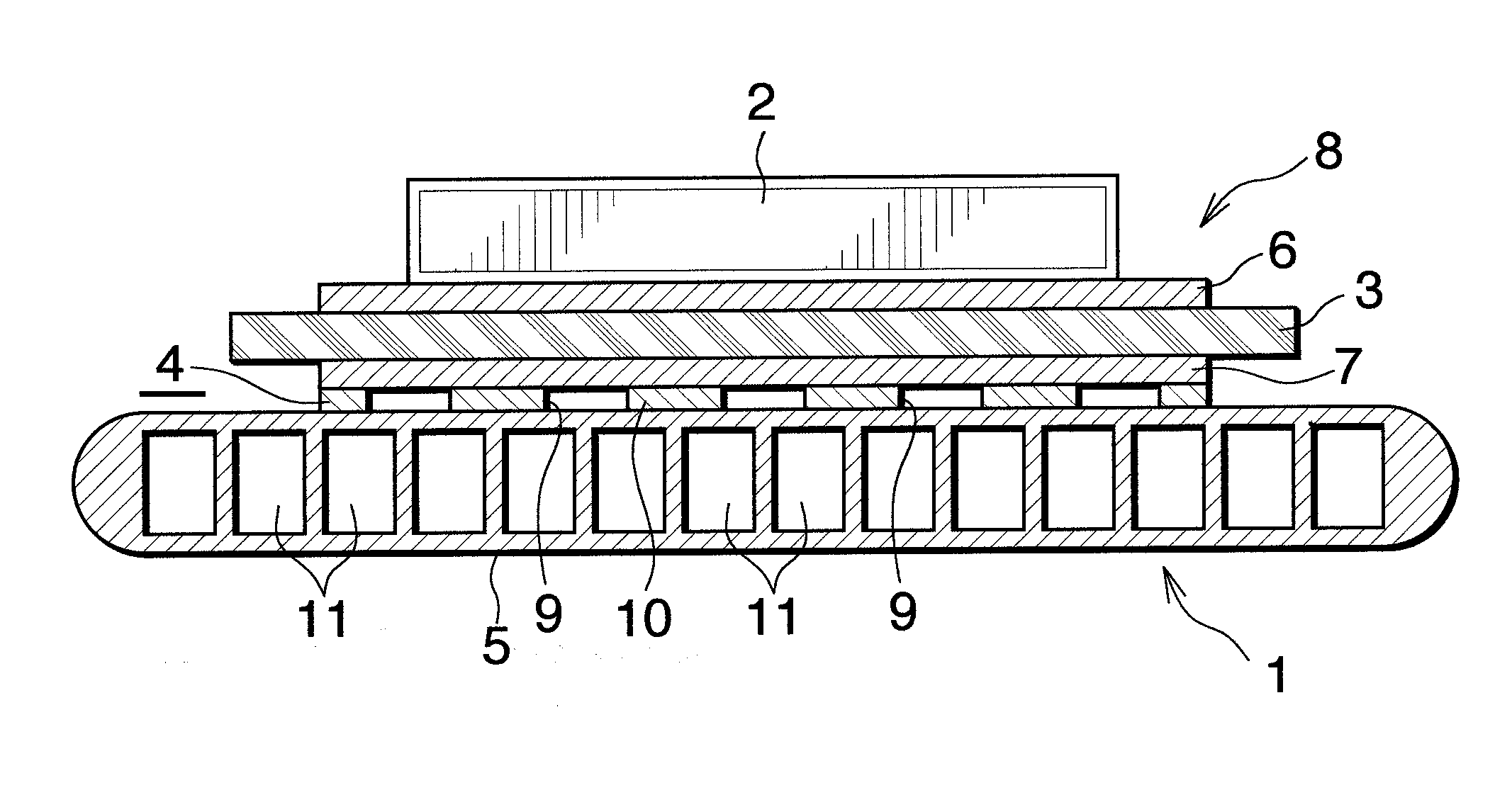

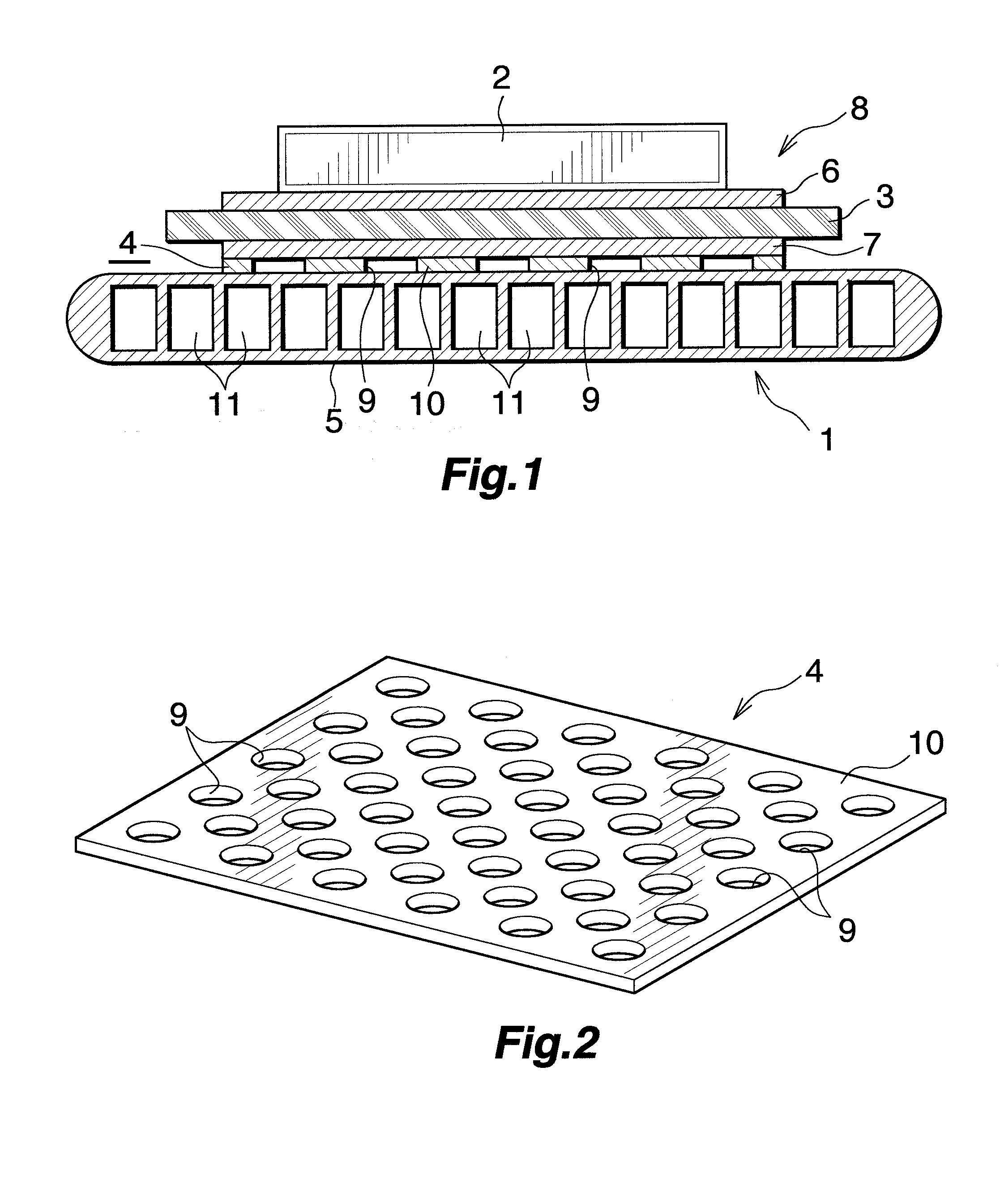

[0056]FIG. 1 shows a portion of a power module which uses a heat radiator of the present invention. FIG. 2 shows a stress relaxation member.

[0057]In FIG. 1, the power module includes a heat radiator (1) and a semiconductor device (2); for example, an IGBT, mounted on the heat radiator (1).

[0058]The heat radiator (1) includes an insulating substrate (3) which is formed of a ceramic and whose upper side serves as a heat-generating-element-mounting side; a stress relaxation member (4) bonded to the lower side of the insulating substrate (3); and a heat sink (5) bonded to the lower side of the stress relaxation member (4).

[0059]The insulating substrate (3) may be formed of any ceramic so long as it satisfies requirements for insulating characteristics, thermal conductivity, and mechanical strength. For example, Al2O3 or AlN is used to form the insulating substrate (3). A circuit layer (6) is formed on the upper surface of the insulating substrate (3), and the semiconductor device (2) is...

second embodiment

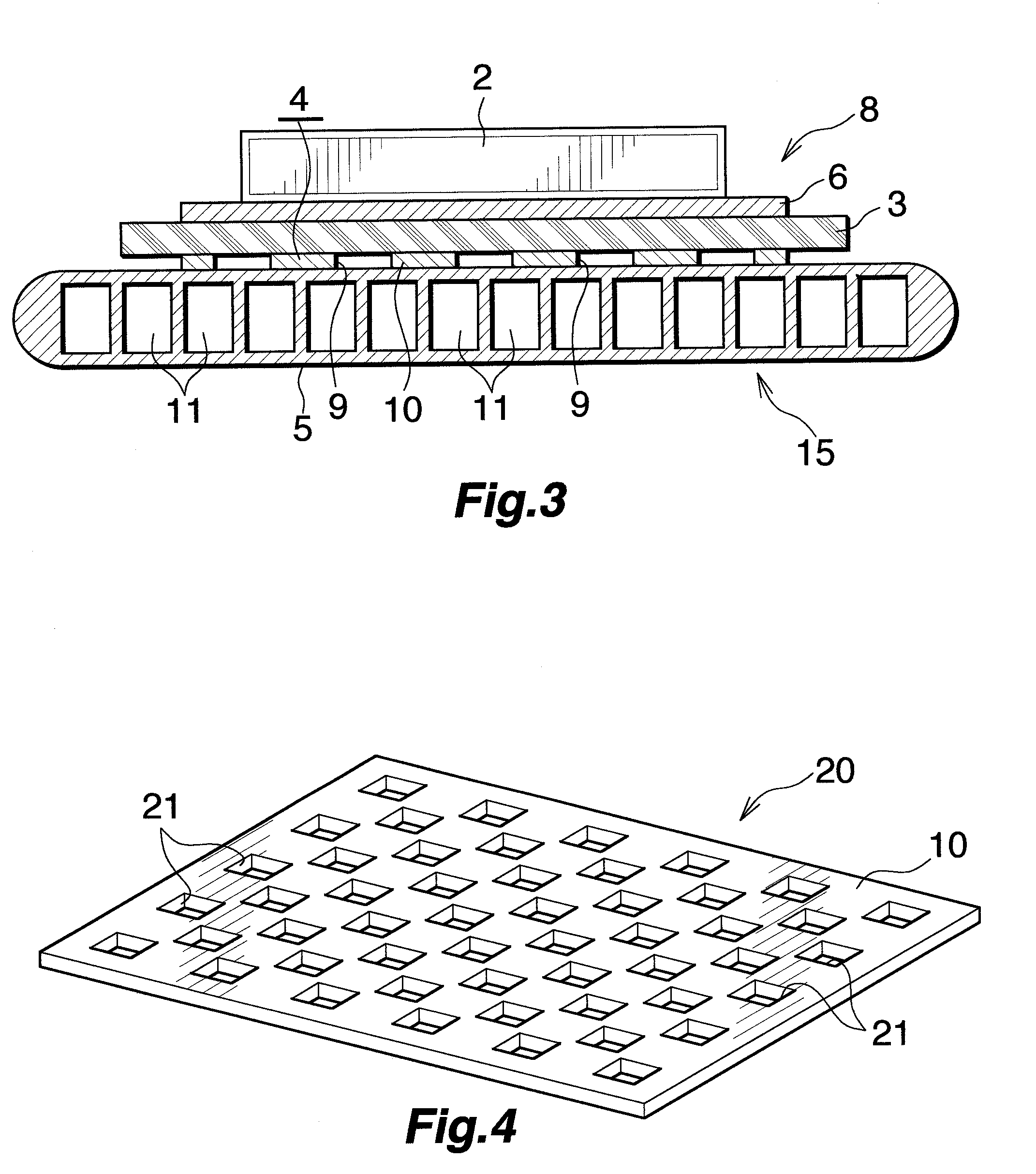

[0065]FIG. 3 shows the heat radiator according to the present invention.

[0066]In the case of a heat radiator (15) shown in FIG. 3, the metal layer (7) is not formed on the lower surface of the insulating substrate (3) of the power module substrate (8); i.e., the stress relaxation member (4) is directly brazed to the insulating substrate (3). This brazing is performed in a manner similar to that of the first embodiment described above.

[0067]FIGS. 4 to 21 show modified embodiments of the stress relaxation member.

[0068]A stress relaxation member (20) shown in FIG. 4 is formed of the aluminum plate (10) in which a plurality of rectangular through holes (21) are formed in a staggered arrangement, and the through holes (21) serve as stress-absorbing spaces. The through holes (21) are formed in at least a portion of the aluminum plate (10) which corresponds to a perimetric portion of the insulating substrate (3); i.e., in the entire region of the aluminum plate (10), including a perimetric...

first modified embodiment

[0095]FIG. 4 Perspective view showing the stress relaxation member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com