Emission control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

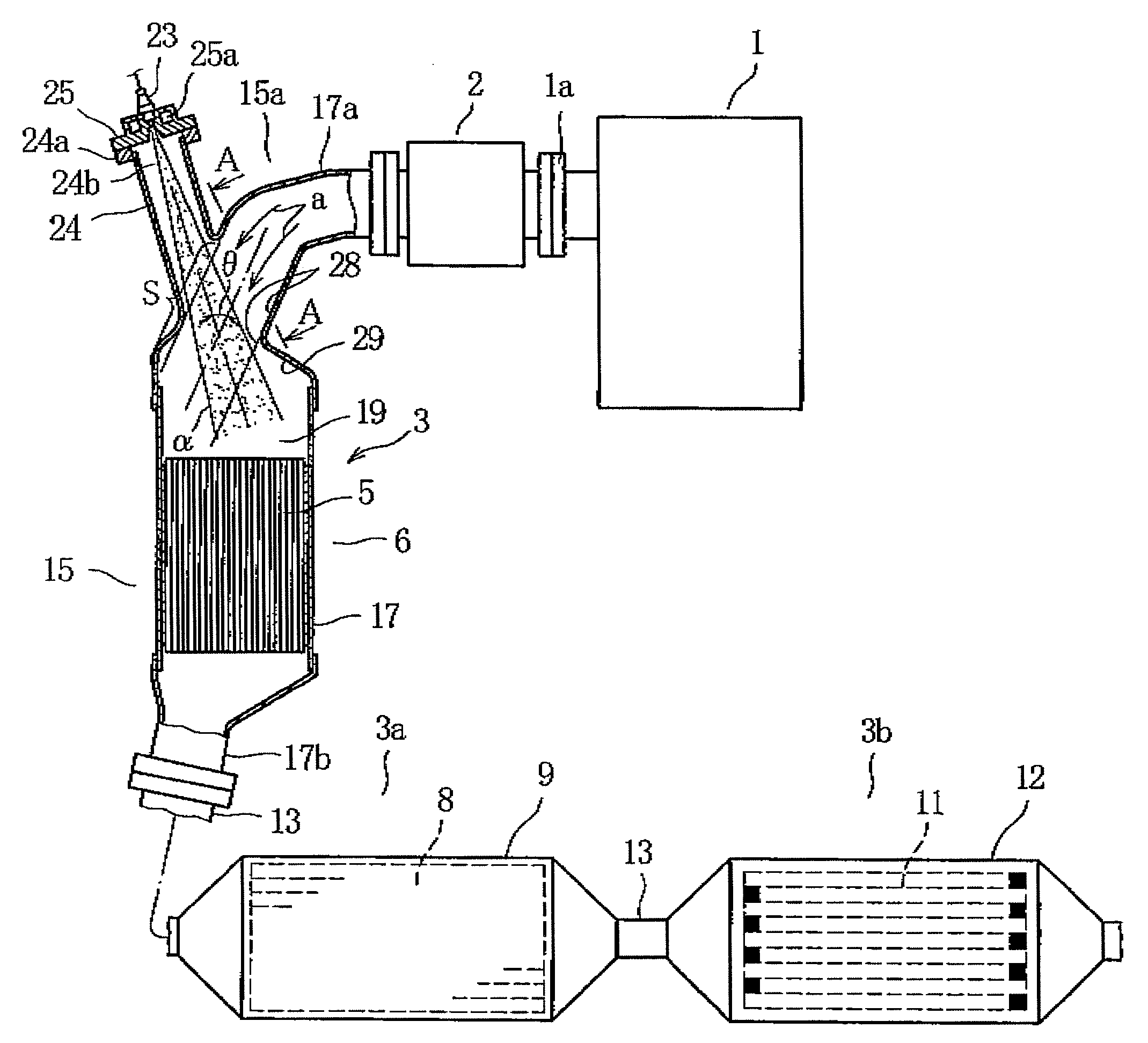

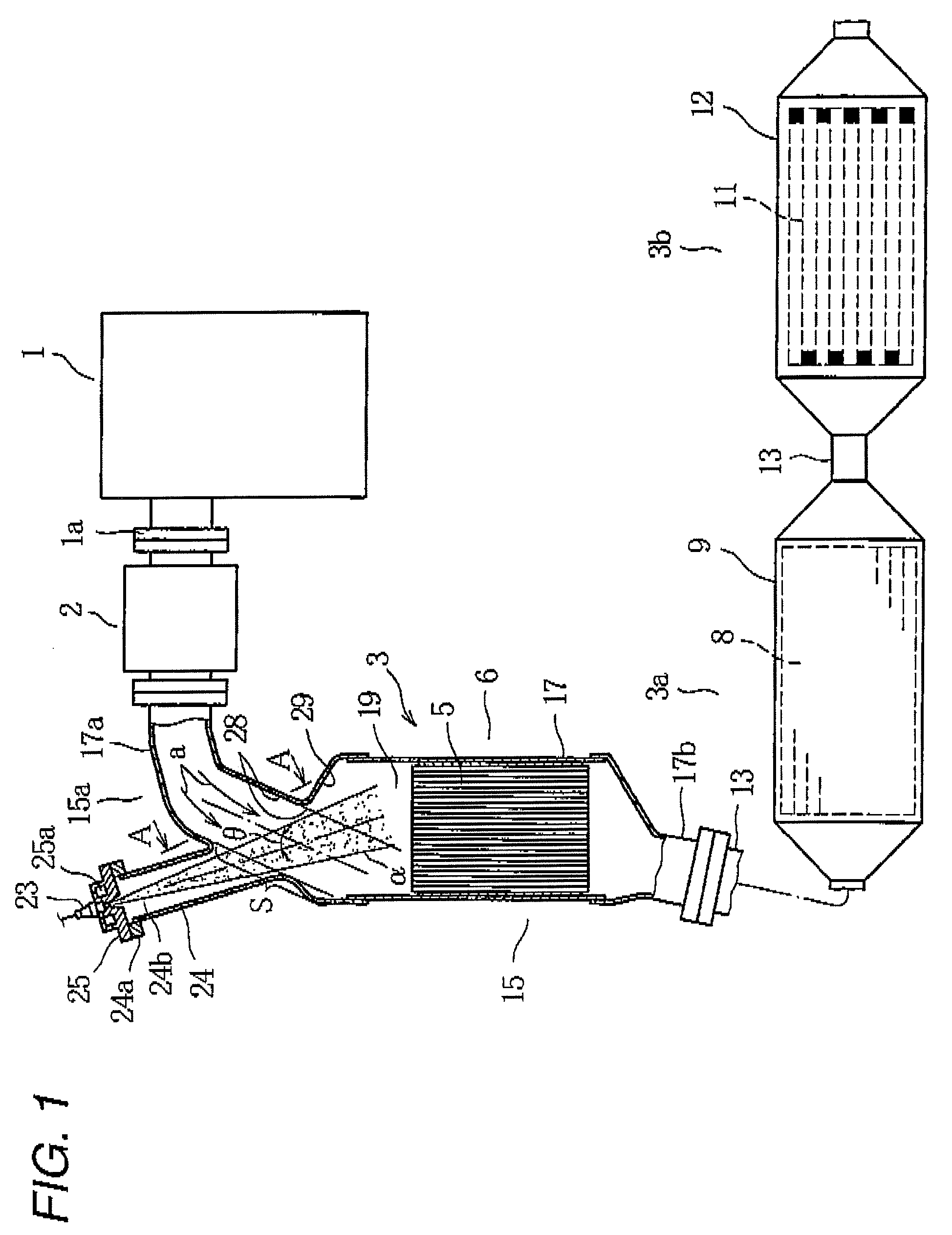

[0038]Hereinafter, the invention will be described based on a first embodiment shown in FIGS. 1 to 3.

[0039]FIG. 1 shows an exhaust system of an internal combustion engine, for example, a diesel engine. In FIG. 1, reference numeral 1 denotes an engine main body of the diesel engine, 1a an exhaust manifold (only part of which is shown) of the engine main body 1 of the diesel engine, and 2 a supercharger or, in this embodiment, a turbocharger connected to an outlet of the exhaust manifold 1a.

[0040]An emission control system 3 is provided at an exhaust outlet of the turbocharger 2. A system in which a NOx removing system 3a for adsorbing NOx (oxides of nitrogen) contained in exhaust gases and periodically reduction removing the adsorbed NOx and a PM (particulate matter) capturing system 3b for capturing PM are combined together is used for the emission control system 3.

[0041]For example, used for the NOx removing system 3a is a configuration in which a catalytic converter 6, a catalyti...

second embodiment

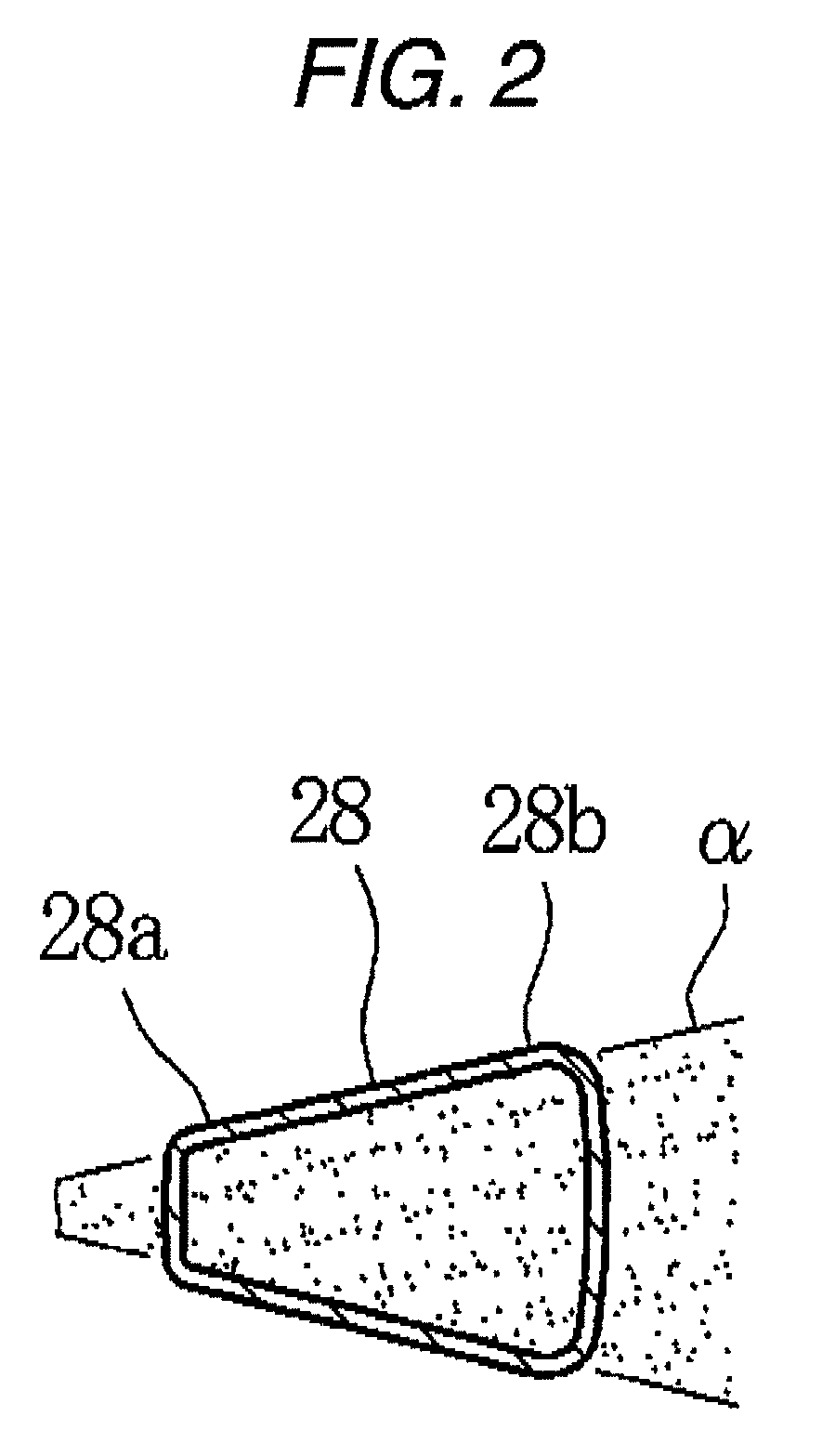

[0064]In particular, in the second embodiment, for example, a curved recessed portion 30 is formed as a release portion on a wall surface of a downstream side exhaust pipe part T which intersects the flow of injected fuel α in such a manner that nothing in the exhaust pipe portion 15 is affected by the flow of injected fuel α when it is deflected. By this recessed portion 30, the contact of the flow of injected fuel α which is deflected with the wall portion of the exhaust pipe part T can be avoided, whereby a good mixture of the exhaust gases with the fuel can be promised. Moreover, since a wall portion of the recessed portion 30 causes exhaust gases which have come into contact with the recessed portion 30 to bounce back towards the flow of injected fuel α as is indicated by arrows b so as to cause the exhaust gases to collide with the fuel in the flow of injected fuel α, it can be expected that the mixture of the fuel with the exhaust gases is promoted further.

[0065]In addition, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com