Engine Management

a technology for engine management and engine components, applied in the direction of electrical control, structural/machine measurement, instruments, etc., can solve the problems of ems technology remaining restricted to parameter based systems, known engine management systems suffering from various problems, and known systems requiring significant initial calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

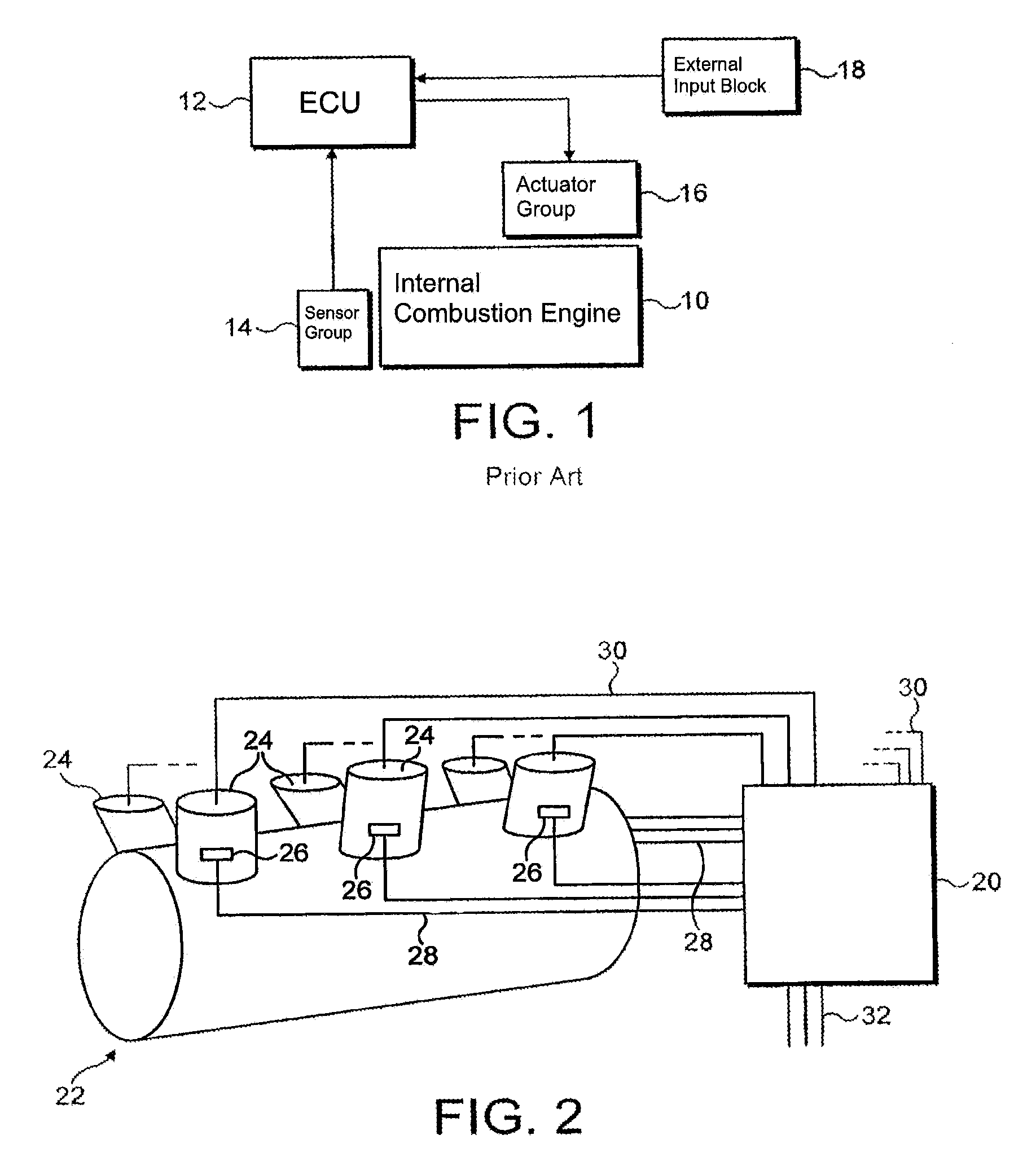

[0022]The following discussion of an embodiment of the invention relates to its implementation in relation to a four stroke combustion ignition engine comprising a diesel engine. However it will be appreciated that the invention can be applied equally to other stroke cycles and types of internal combustion engines including spark-ignition engines, with appropriate changes to the model parameters. Those changes will be apparent to the skilled person and only the best mode presently contemplated is described in detail below. Like reference numerals refer to like parts throughout the description.

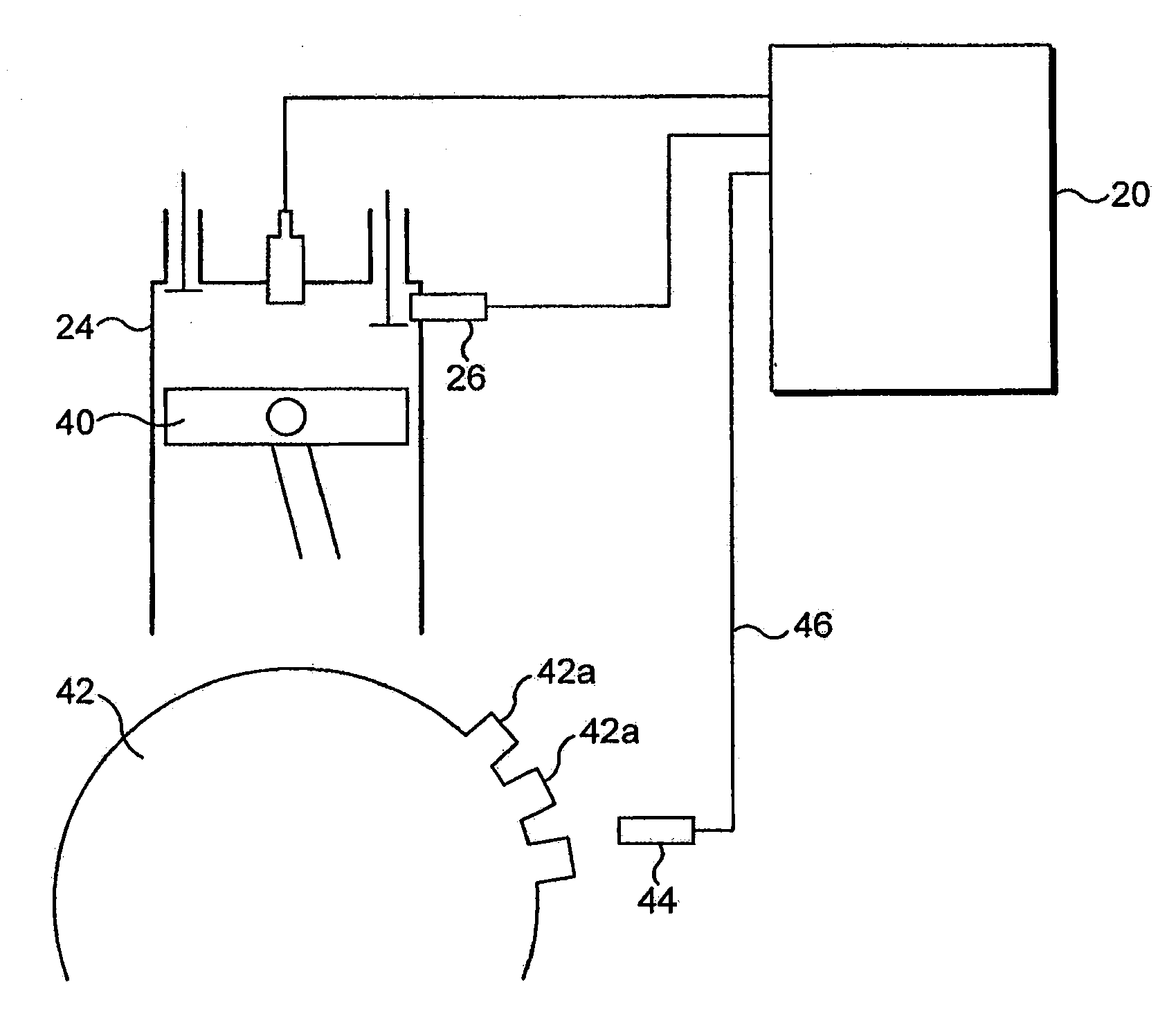

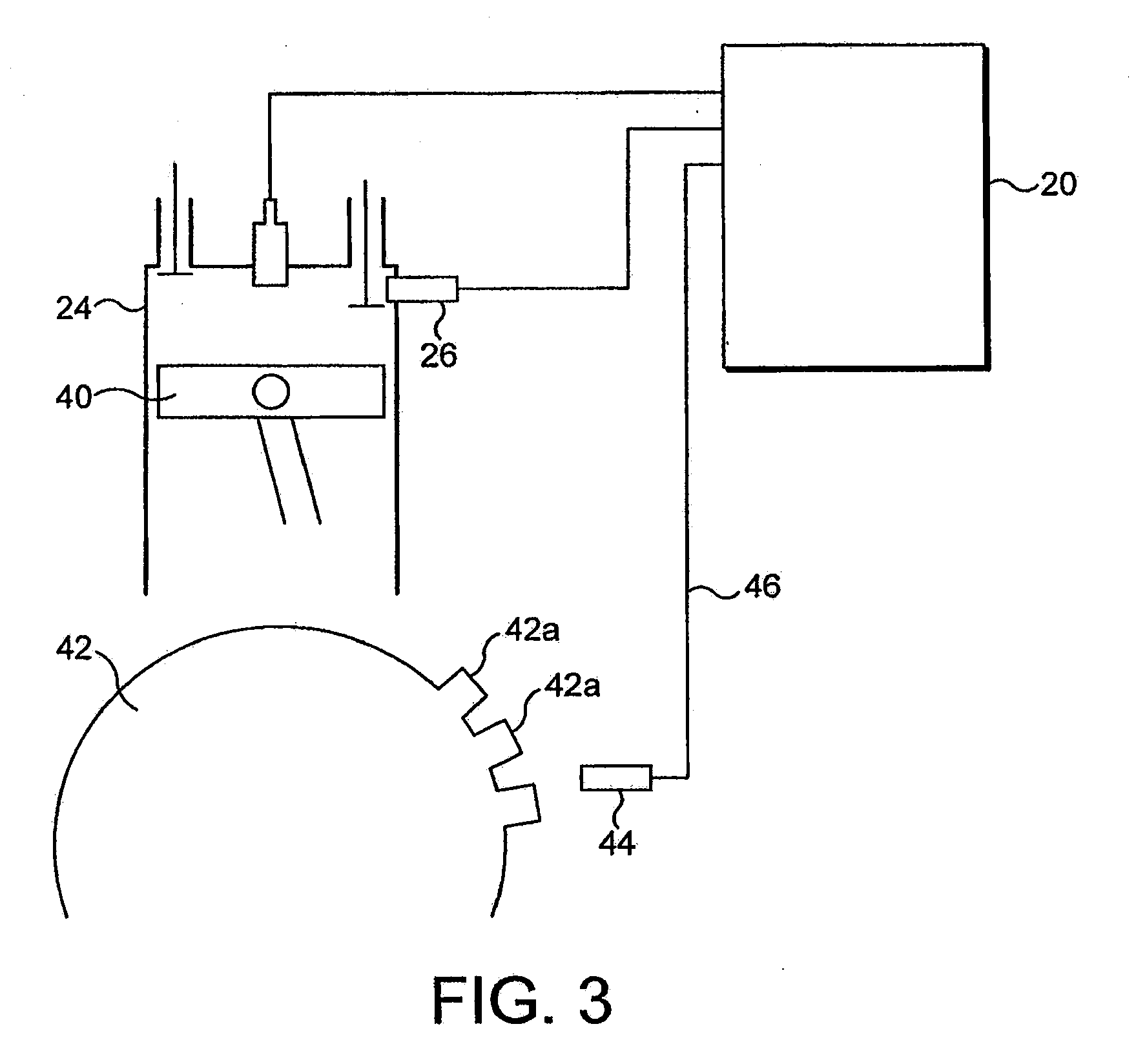

[0023]FIG. 2 is a schematic view showing the relevant parts of an engine management system according to the present invention in conjunction with a six cylinder engine. An engine control unit is designated generally 20 and controls an engine designated generally 22. The engine includes six cylinders designated generally 24. Each cylinder includes a pressure sensor 26 which connects to the ECU v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com