Electrode for electrochemical device and electrochemical device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

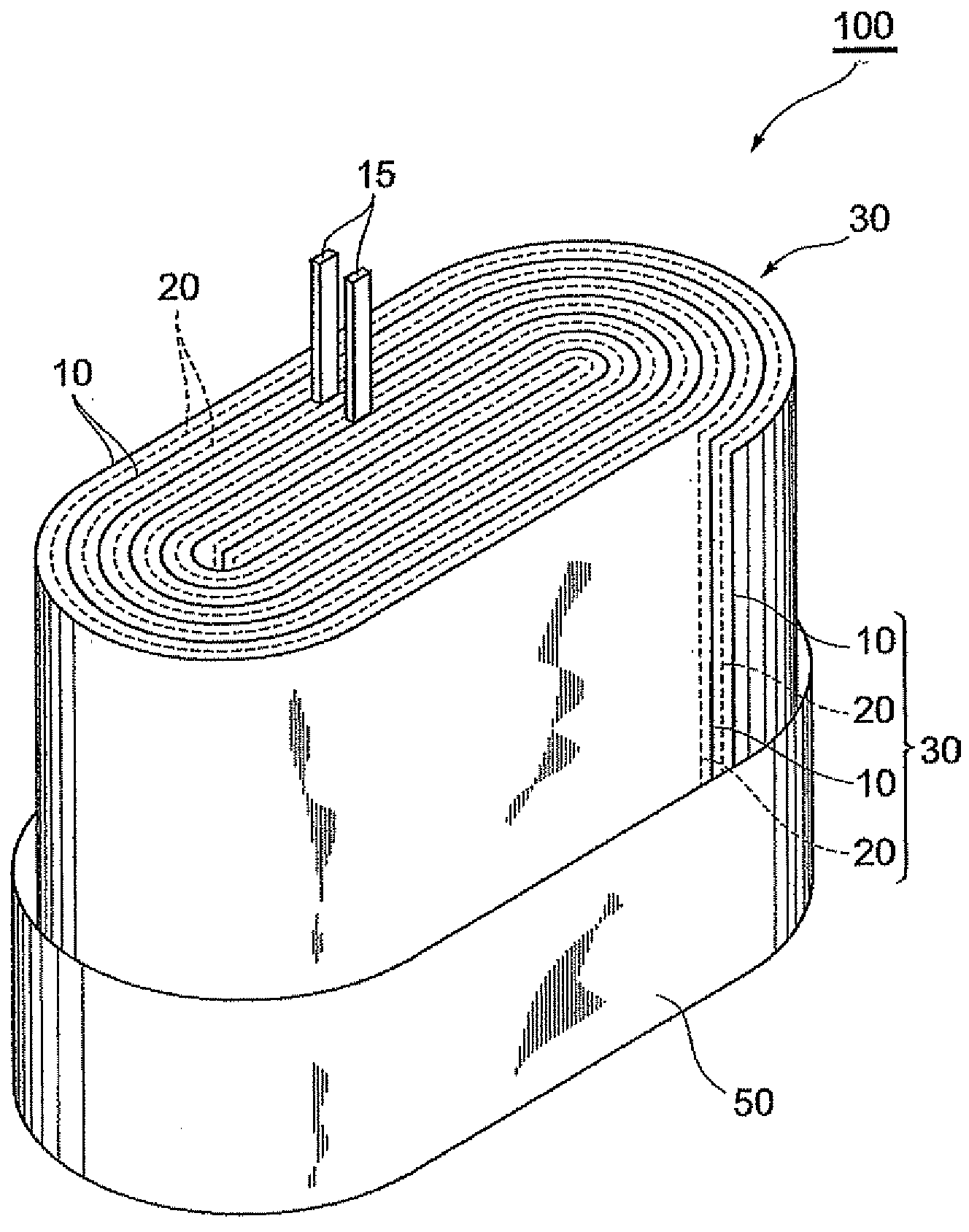

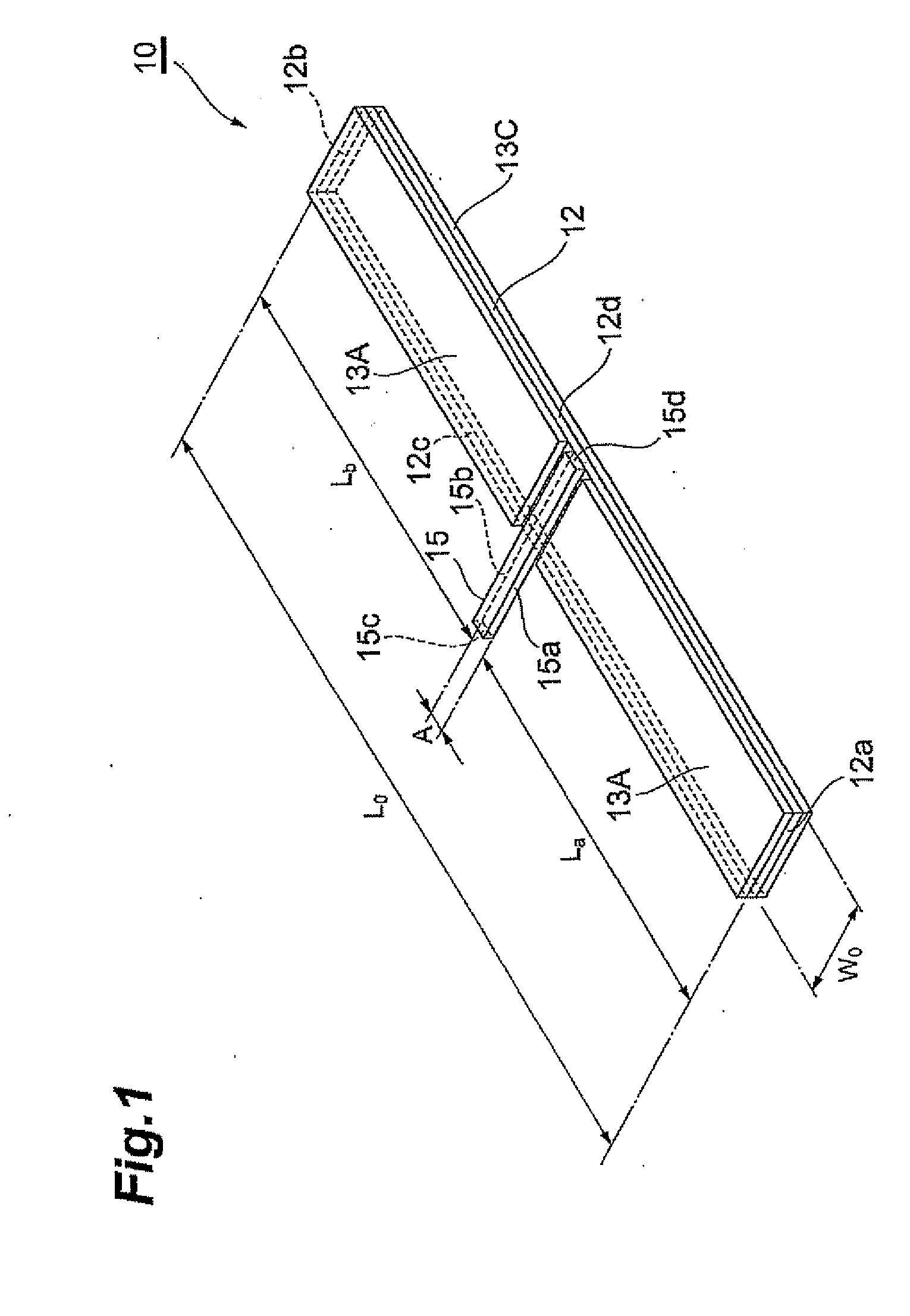

[0022]An electrode for electrochemical devices 10 according to a first embodiment will be explained with reference to FIG. 1. The electrode for electrochemical devices 10 comprises mainly a collector 12, active material layers 13A, 13C containing an active material, and a lead 15.

[0023]The collector 12 is a conductive member in the form of a rectangular elongated plate. Although not particularly limited thereto, the material of the collector is preferably a metallic material, such as copper, aluminum or nickel. For instance, the electric resistivity ρ of copper, aluminum and nickel are 1.68×10−8 Ωm, 2.65×10−8 Ωm, 6.99×10−8 Ωm, respectively. The thickness of the collector is not particularly limited, and may range from 10 to 50 μm. Also, the length L0 in the longitudinal direction and the length W0 in the direction (width direction) perpendicular to the longitudinal direction are not particularly limited. The length L0 in the longitudinal direction may range, for instance, from 80 to...

second embodiment

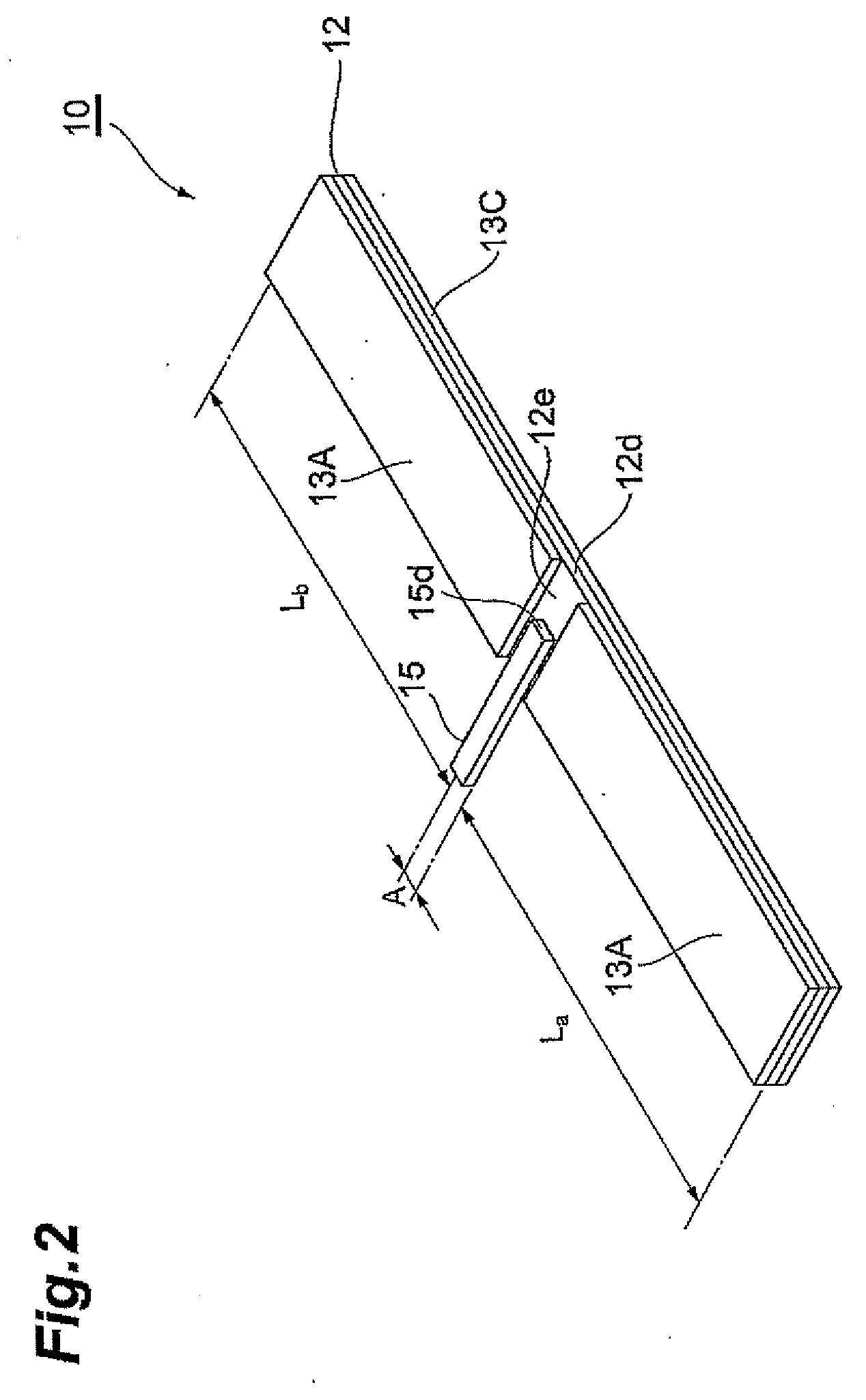

[0038]An electrode for electrochemical devices 10 according to a second embodiment is explained next with reference to FIG. 2. The electrode for electrochemical devices 10 according to the present embodiment differs from the electrode for electrochemical devices according to the first embodiment in the shape of the lead 15, and thus only this feature will be explained. In the lead 15 according to the second embodiment, the end face 15d does not protrude up to the side face 12d of the collector 12, but is positioned over the surface 12e of the collector 12. Such an electrode for electrochemical devices 10 elicits the same effect as that of the first embodiment.

third embodiment

[0039]An electrode for electrochemical devices 10 according to a embodiment is explained next with reference to FIG. 3. The electrode for electrochemical devices 10 according to the present embodiment differs from the electrode for electrochemical devices according to the first embodiment in the shape of the lead 15, and thus only is feature will be explained. The lead 15 according to the third embodiment is not provided on the front face or rear face of the collector 12 but on the side face 12d of the collector 12. As a result, the active material layer 13A is not split but formed as a singe unit, as is the case with the active material layer 13C. Such a lead 15 can be easily formed by cutting the collector 12 and the lead 15 out of a singe conductive plate. Such an electrode for electrochemical devices 10 elicits the same effect as that of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com