Low impedance probe structure and purpose

A low-impedance, probe-based technology, which is applied to components of electrical measuring instruments, measuring devices, instruments, etc., can solve problems such as uneven electroplating metal layers, increased production costs, and unstable welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is easy to implement for the professional people, and in conjunction with accompanying drawing the present invention is described in detail as follows:

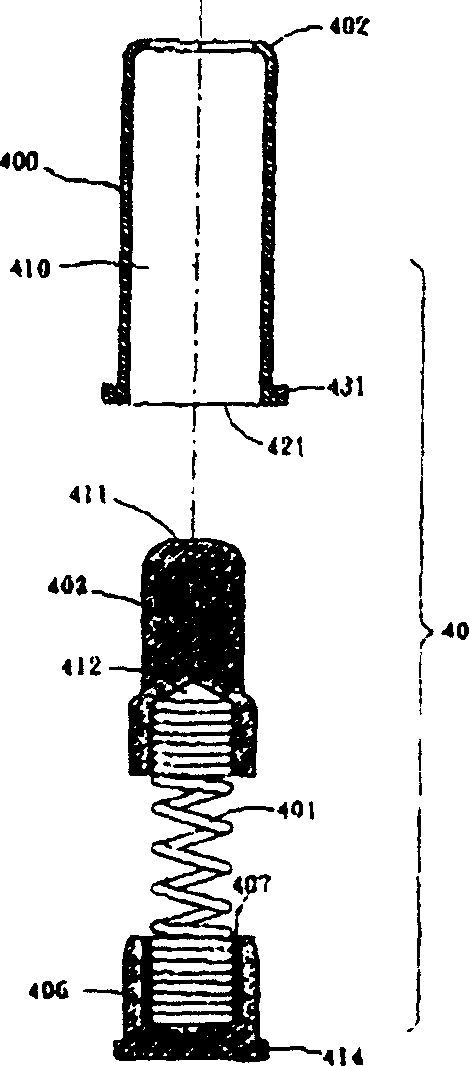

[0043] image 3 The shown probe structure of the present invention includes:

[0044] A gold-plated sleeve 400 is a hollow circular tube with two ends open, one end is a retracted inner side 402, the other end is provided with a stop side 421, and a convex portion extending from the stop side 421 to both sides 431, and an action space 410 between the stopper 402 and the retracted side 421;

[0045] Put a gold-plated needle 403 into the retracted side 402 from the stop side 421 to expose the gold-plated needle 403, and put a gold-plated spring 401 into an actuation space 410 from the stop side 421, and finally place the seat 406 by The stop side 421 is plugged in so that the stop side 421 is closed, thereby constituting the probe structure of the present invention.

[0046] Among them, the gold-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com