PV water heater with adaptive control

a pv water heater and adaptive control technology, applied in the direction of heating types, domestic hot water supply systems, lighting and heating apparatus, etc., can solve the problems of difficult installation, weight, and relatively high initial cost, and achieve the effect of improving the efficiency of known pv water heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

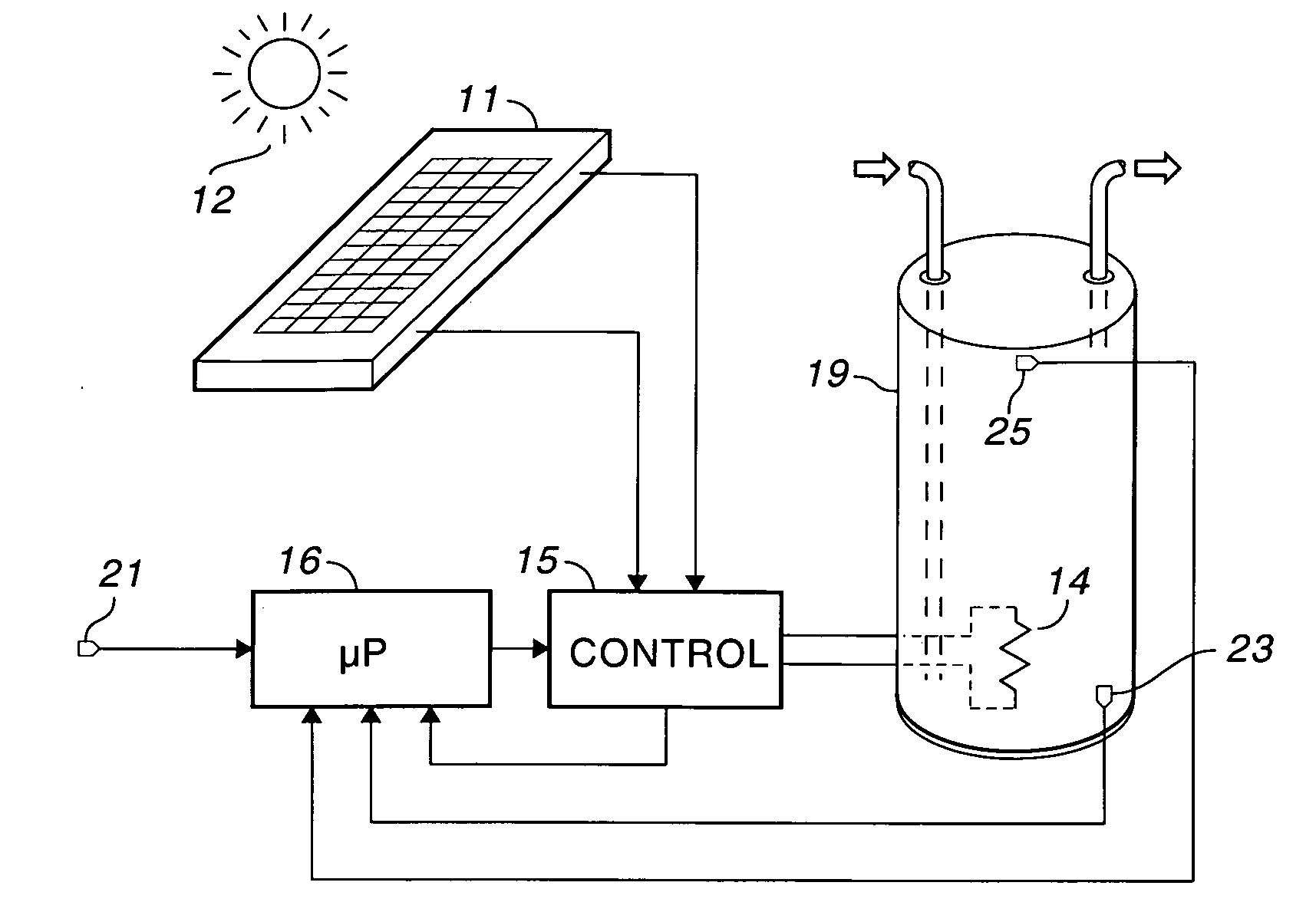

[0017]In the FIGURE, photoelectric solar module 11 converts photons from sun 12 into an electric current. The electric current is applied to heater element 14 by control circuit 15. Heater element 14 converts the electric current to heat, thereby heating the water in tank 19. Solar module 11 can be of any current or future design. The only constraint on the design is that heater element 14 be compatible with the voltage and current produced by module 11.

[0018]Preferably, control circuit 15 uses pulse width modulation (PWM) to control power, thereby minimizing losses within control circuit 15. Semiconductor or solid state switching is preferred to relays, although either can be used in control circuit 15 for varying the power supplied to heater element 14. Heater element 14 includes one or more electrodes. If plural electrodes are used, then control circuit 15 can switch the electrodes in series or parallel combinations to provide the desired level of heating. Alternatively, PWM and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com