Outboard motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

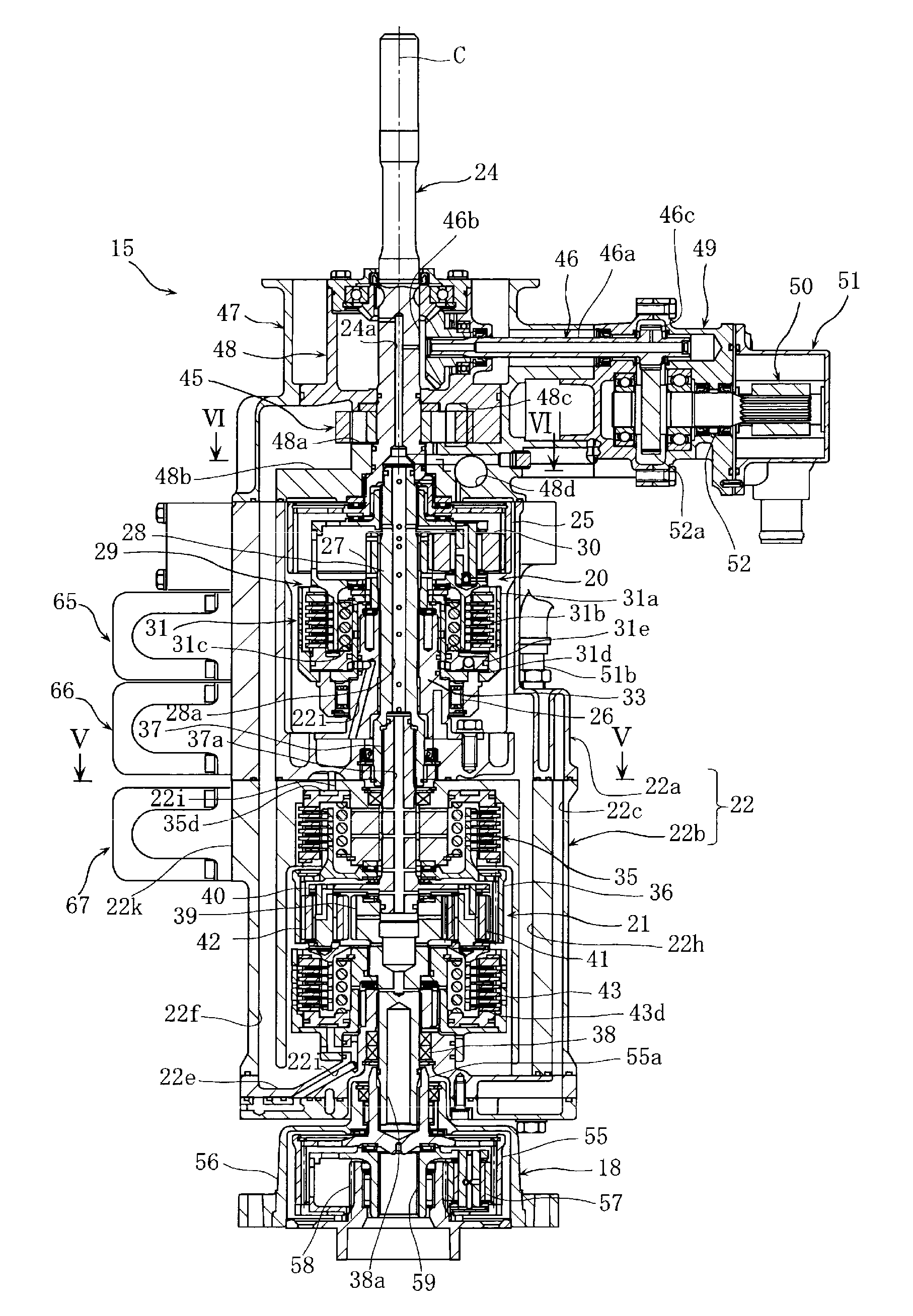

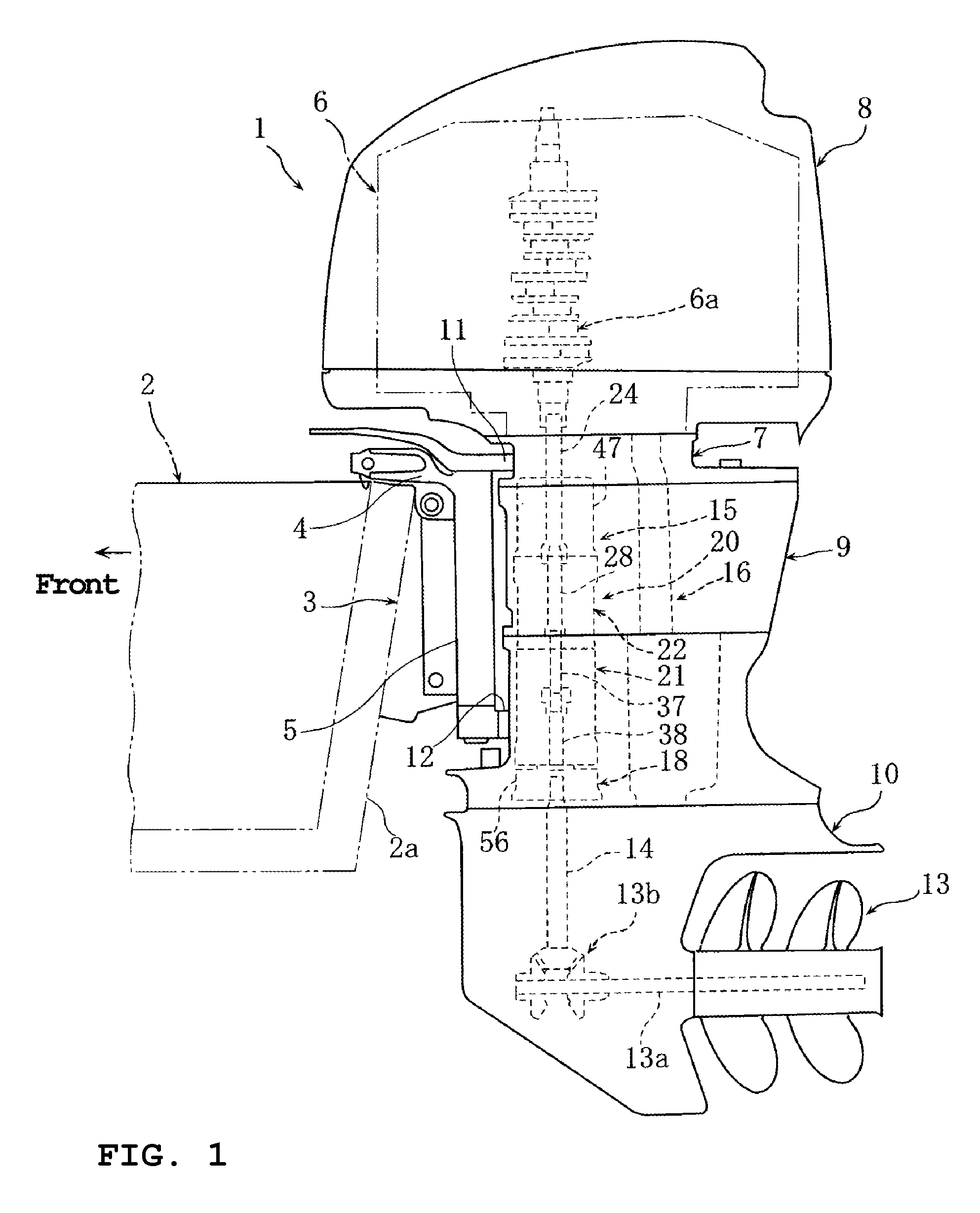

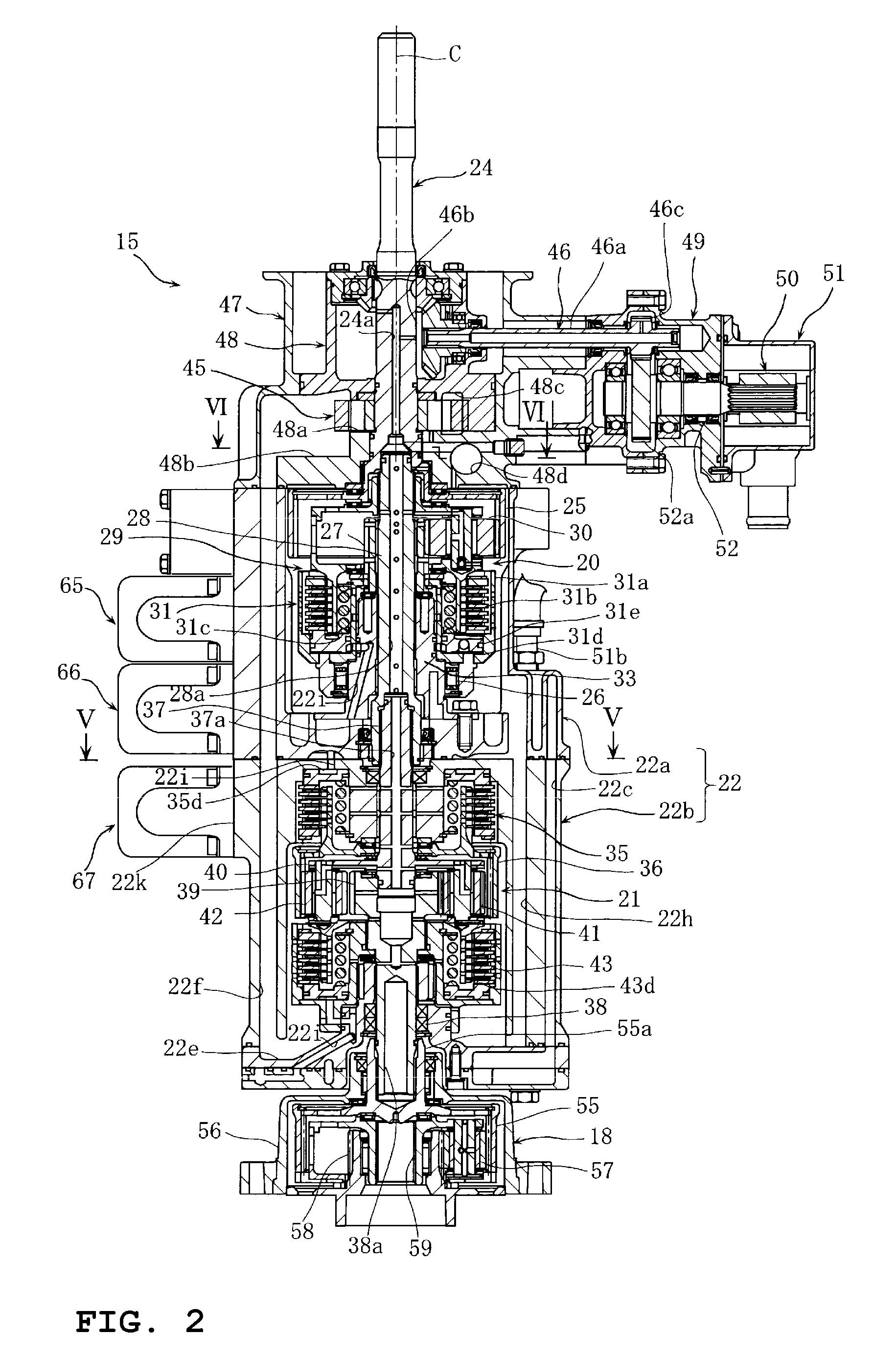

[0027]Preferred embodiments of the present invention will be described hereinafter with reference to attached drawings.

[0028]FIGS. 1 through 10 are drawings for describing an outboard motor in accordance with preferred embodiments of the present invention. Front, rear, right, and left in descriptions of the preferred embodiments denote front, rear, right, and left in the view as seen from the rear of a watercraft unless otherwise specified.

[0029]In the figures, reference numeral 1 denotes an outboard motor installed in a stern 2a of a hull 2. The outboard motor 1 is supported swingably in the vertical direction by a clamp bracket 3 fixed to the hull 2 via a swivel arm 4 and supported to be steerable to the right and left via a pivot portion 5.

[0030]The outboard motor 1 has an engine 6 arranged to generate power, an exhaust guide 7, a cowling 8, an upper case 9, and a lower case 10.

[0031]The engine 6 includes a vertically oriented crankshaft 6a disposed in a generally vertical direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com