Cooling plate for an iron- or steelmaking furnace

a technology of cooling plate and iron ore, which is applied in the direction of chamber doors, laminated elements, light and heating apparatus, etc., can solve the problems of inability to achieve far, and achieve the effects of reducing pressure loss, avoiding discontinuities in flow patterns, and pre-determined pressure losses in individual cooling circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

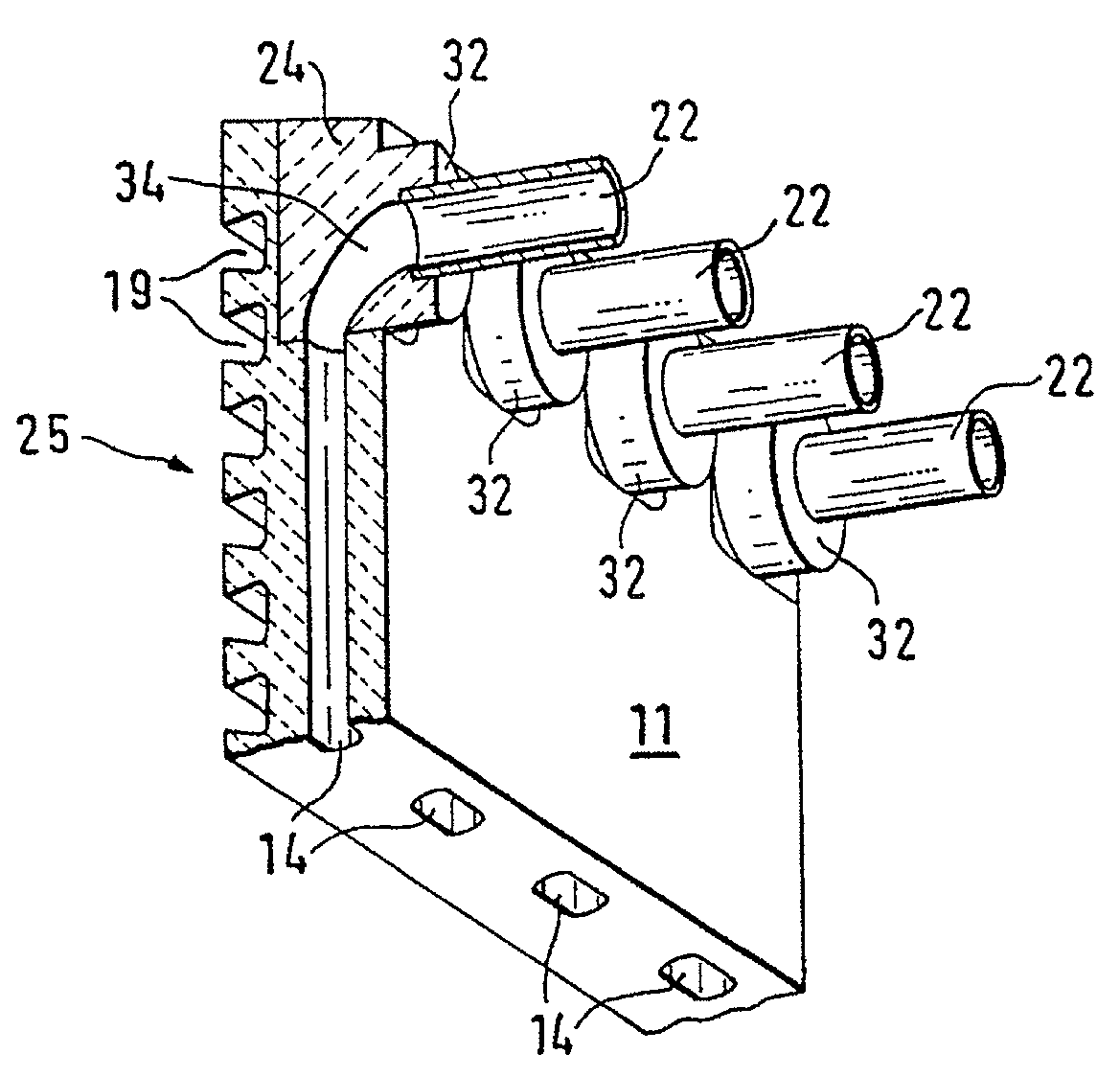

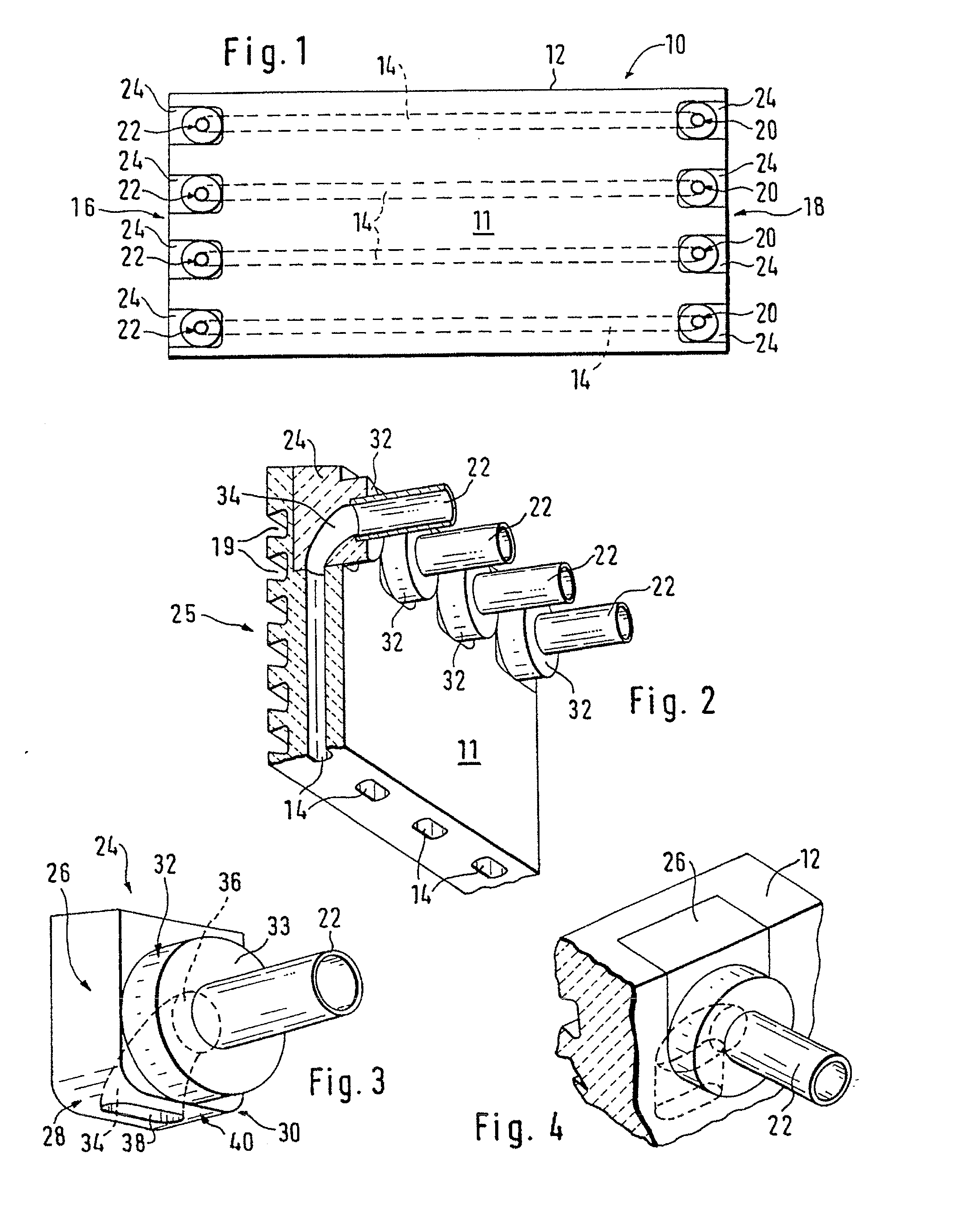

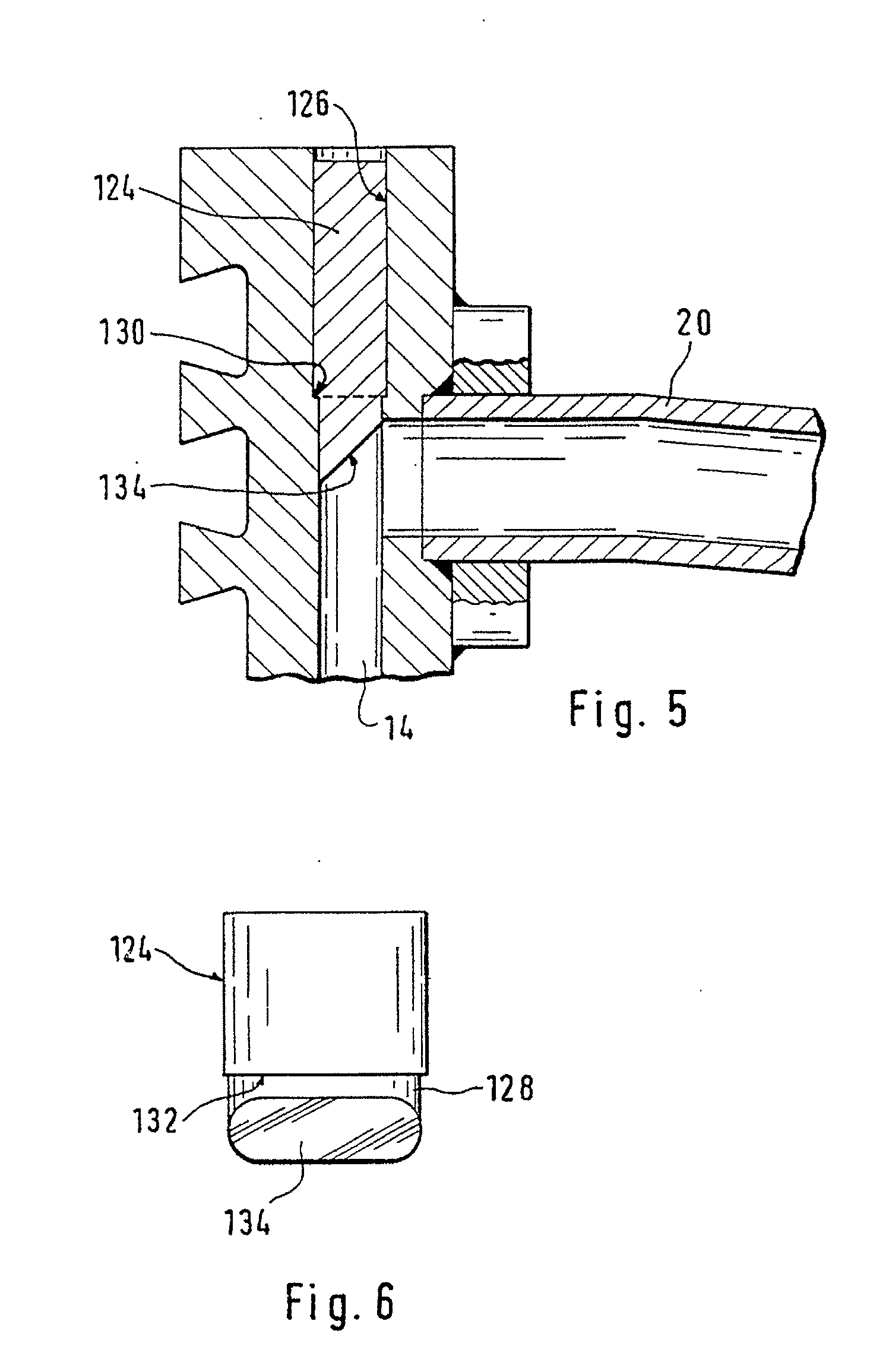

[0032]The cooling plate 10 shown consists essentially of a cooling plate body 12 made from copper or a copper alloy with a rectangular surface. Four straight cooling ducts 14, which extend parallel with the surface through the cooling plate body 12 from one end 16 to the opposite end 18, are integrated in the cooling plate body 12. This cooling plate body 12 was advantageously manufactured by the method described in the subsequently published patent application WO 98 / 30345. A preform of the cooling plate body 12 was continuously cast in a continuous casting mould, whereby rod-type inserts in the casting duct produced ducts running in the casting direction, which form the cooling ducts 14. As shown in FIG. 2 the cross-section of the integrally cast ducts 14 has an oblong shape with its smallest dimension at right angles to the plate. A plate was cut out of this continuously cast preform by two cuts at right angles to the casting direction, the two end faces 16 and 18 of the cooling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractory | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com