Unequal length alternating hydraulic cylinder drive system for continuous material output flow with equal material output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

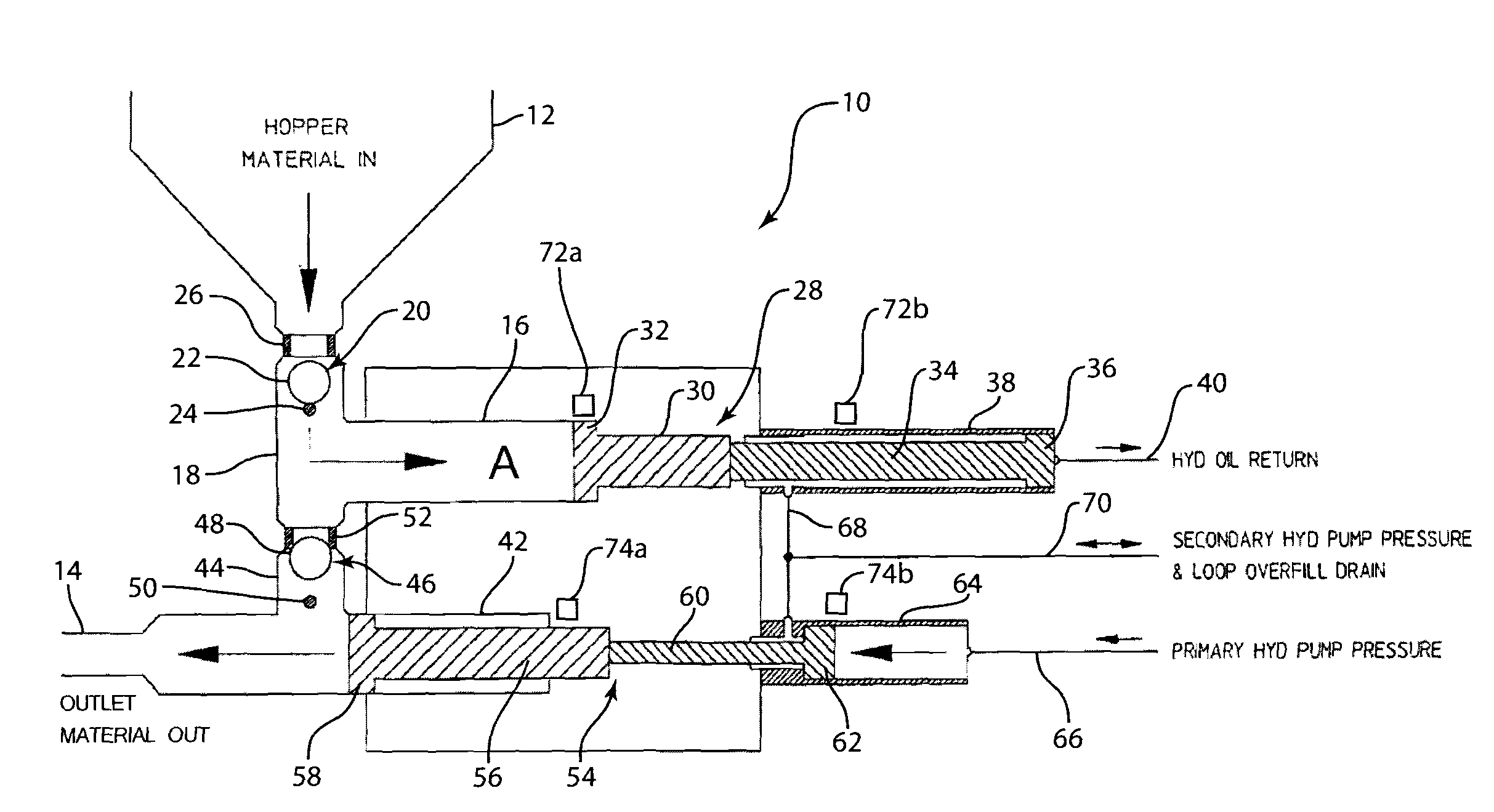

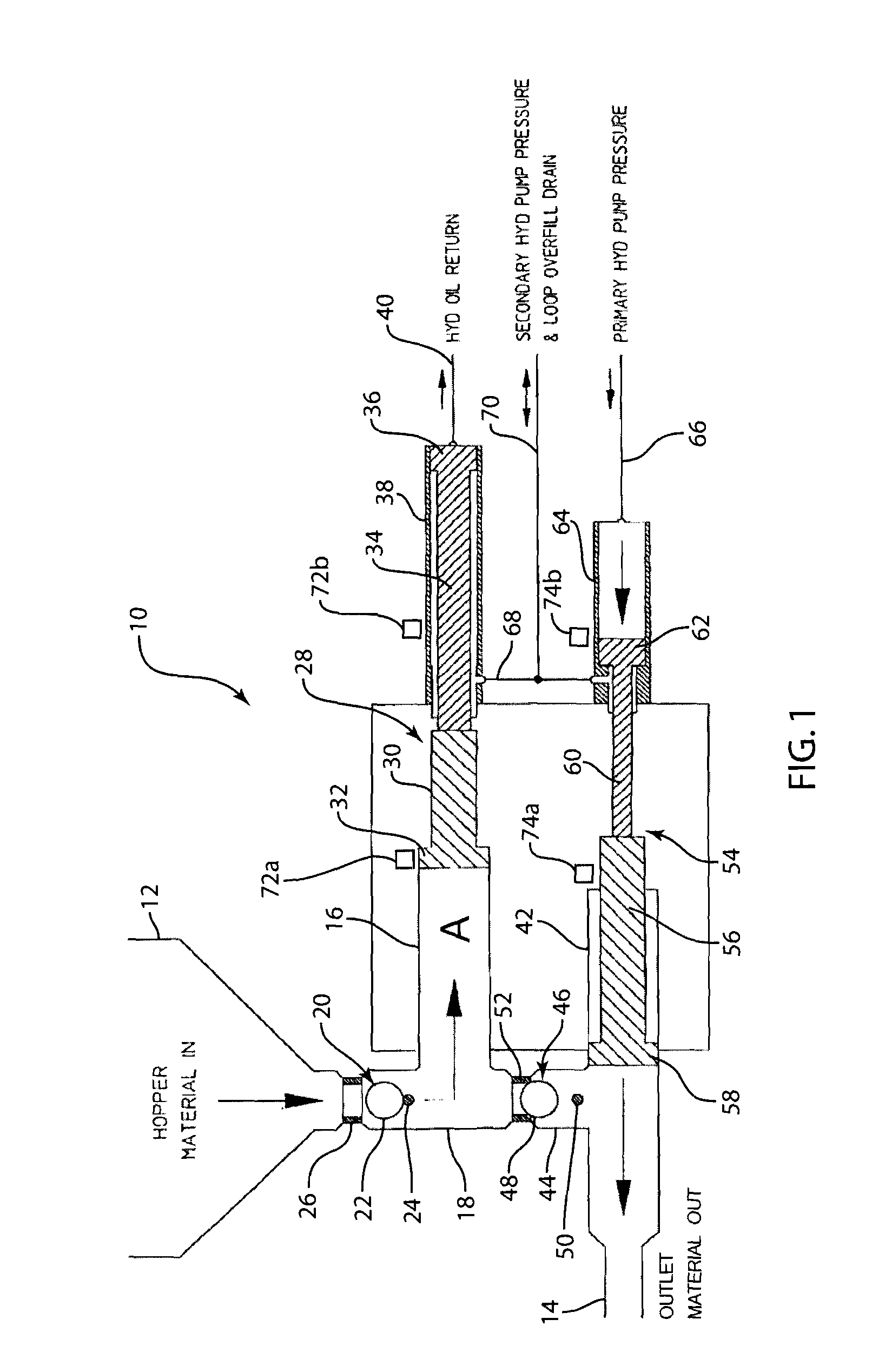

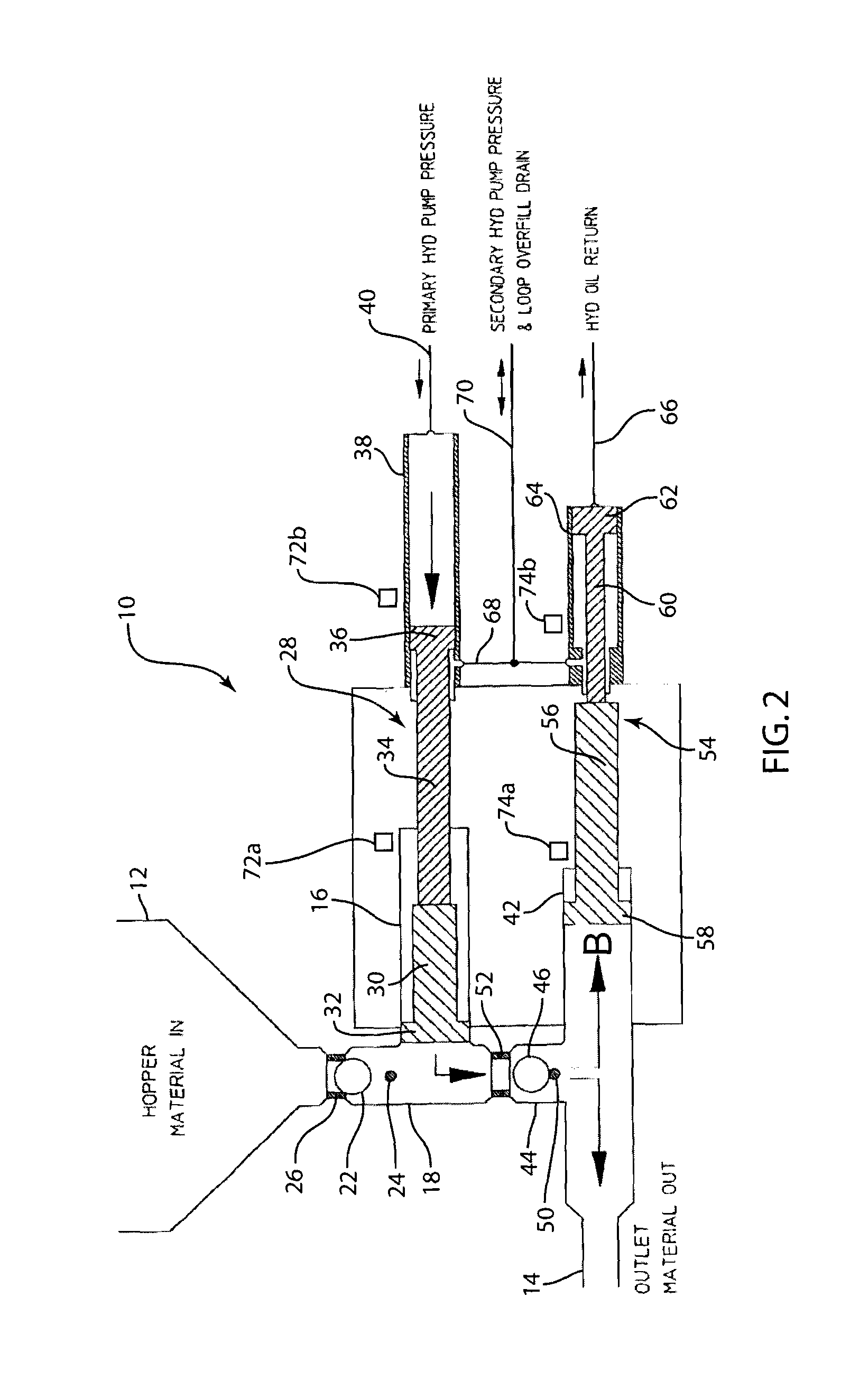

[0025]Referring to the drawings, a hydraulic cylinder drive system 10 forms a constant delivery pump used to provide a pressurized supply of abrasive, compressible fluid material, typically cement, plaster, mortar or the like, from a reservoir or hopper 12 to an outlet 14. Material delivered to the outlet 14 is normally directed to a spray nozzle for distribution to a desired surface, such as a building wall.

[0026]The system 10 includes a primary hydraulically driven pumping unit defined by a primary material cylinder 16 have a feed line 18 in communication within hopper 12 and an interior volume A at a head of the cylinder 16. A first one-way check valve 20 is positioned in feed line 18 between hopper 12 and primary material cylinder 16. The check valve 20 is a conventional mechanical design having a ball 22 movable between a stop 24 and a seat 26. The check valve 20 allows flow of material from hopper 12 into material cylinder 16 through the line 18, but blocks flow in the reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com