Moisture-permeable material for wigs and wig or under cap for wig having the moisture-permeable material

a technology of moisture-permeable materials and wigs, which is applied in the direction of wigs, hair accessories, headwear, etc., can solve the problems of difficulty in achieving the effect of moisture-permeable materials, limited styles that can be created, and discomfort, and achieves superior moisture-permeability, superior durability, and superior smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

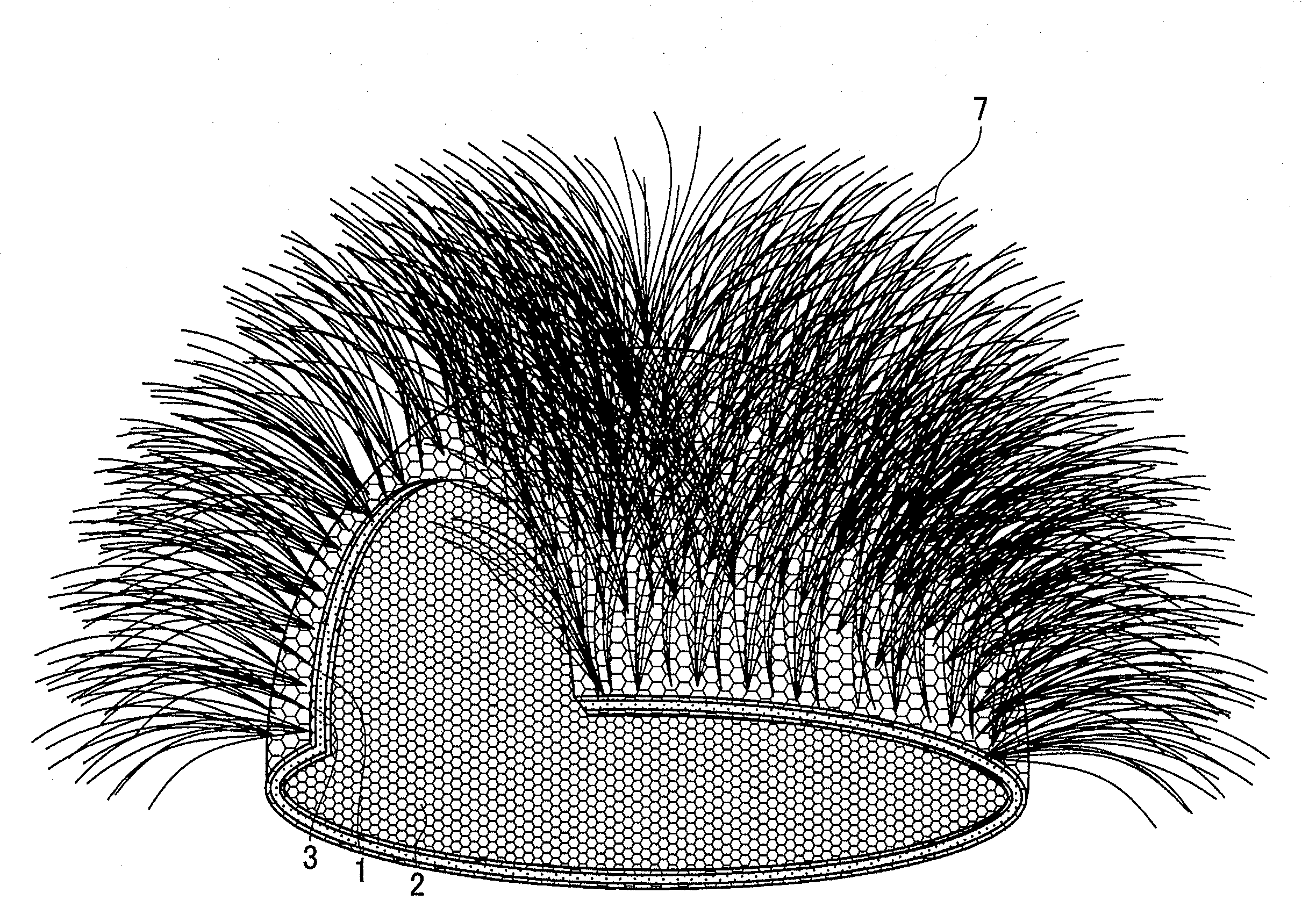

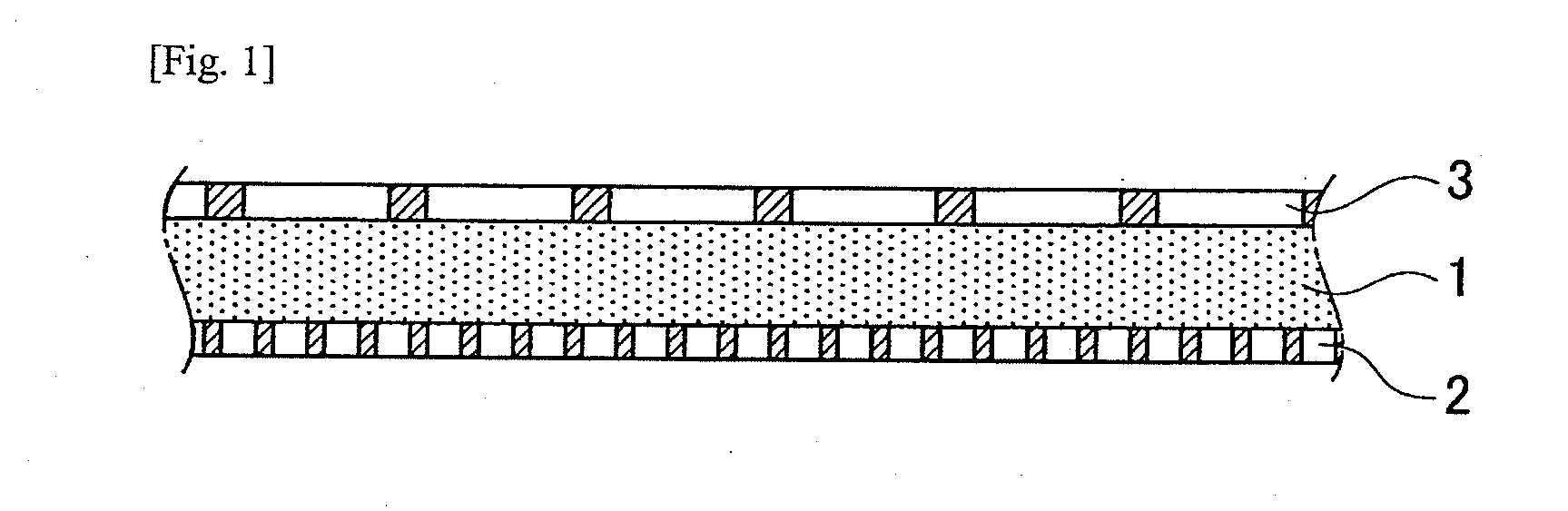

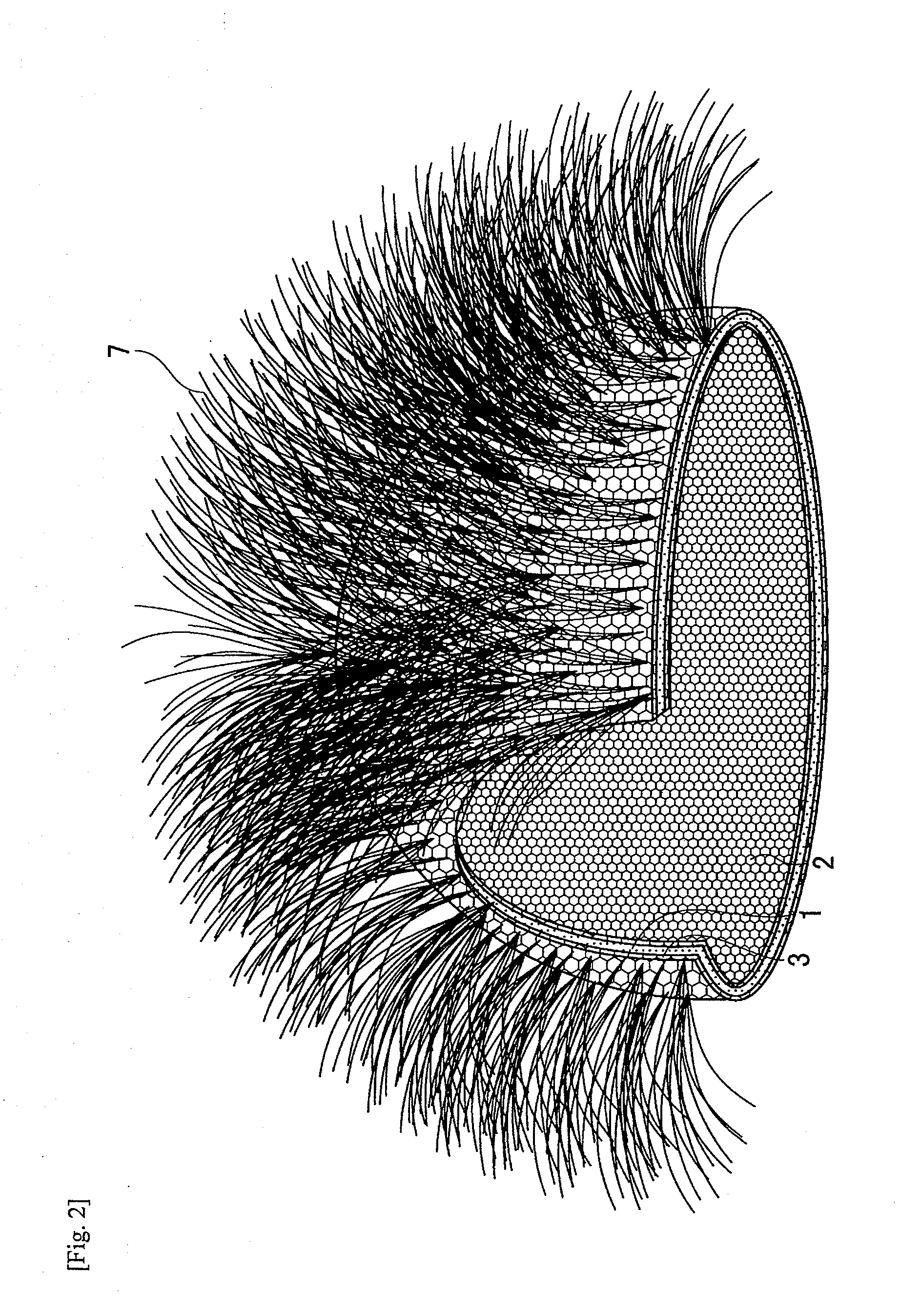

[0054]As shown in FIG. 1, a hot-melt type urethane resin (manufactured by Mitsui Takeda Chemicals Inc.; product No. Takernelt MA3229K) was applied in a dotted fashion in an amount of 15 g / m2 to a surface of a porous polyurethane layer 1 prepared by the dry method, and a polyester mesh 2 (texture: tricot; blending ratio: polyester 100%; threading: 84T / 36f; course: 44 / inch; wale: 28 / inch) was laminated thereon. On the other hand, a net fiber layer 3 (texture: tricot; blending ratio: nylon 100%; threading: 66 nylon, 22T / 7f; course: 42 / inch; wale: 28 / inch) was bonded to a back surface of the porous polyurethane layer 1 by using a hot-melt type urethane resin (manufactured by Mitsui Takeda Chemicals Inc.; product No. Takernelt MA3229K) to prepare a moisture-permeable material for wigs as shown in FIG. 1. Further, a hair material was planted therein to prepare a wig. Table 1 shows physical properties and performance of the wig.

TABLE 1ExampleExampleExampleExampleExampleExample123456PeelVer...

example 2

[0055]A resin solution obtained by dissolving a urethane elastomer of a thermoplastic resin (manufactured by Nippon Polyurethane Industry Co., Ltd.; product name code: E-985) in an organic solvent (8:2 mixture liquid of dimethyl formamide and methylethyl ketone) was applied to a male plaster mold of a head configuration, and was dried to be formed into the head configuration, thus preparing an artificial skin type wig base having a thickness of 0.2 mm.

[0056]Next, the moisture-permeable material for wigs of Example 1 was fixed to the male plaster mold by a staple by using a gun tacker such that the net layer is on the lower side, and a 30% water-soluble resin solution of polyvinyl alcohol (manufactured by Kuraray Co., Ltd.; product name: Kranol) was applied thereto, and was then dried at 100° C. for six hours to be formed into the head configuration.

[0057]Subsequently, a moisture-permeable material for wigs formed into the head configuration was aligned with and superimposed on a wig...

example 3

[0058]A so-called net obtained by plain-weaving polyester monofilaments having a thickness of 0.10 mm in 60 meshes / inch was stretched over a male plaster mold of a head configuration so as not to involve wrinkles or sagging, and was fixed by a staple by using a gun tacker; then, a solution obtained by diluting a two-liquid type urethane thermoplastic resin (ADAPT E-No. 2 manufactured by Nissin Resin Co., Ltd.) in an organic solvent (8:2 mixture liquid of dimethyl formamide and methylethyl ketone) was applied to the net, and was heated at 100° C. for ten hours to prepare a net formed into the head configuration. The moisture-permeable material for wigs of Example 1 was formed in the same manner as in the case of the artificial skin of Example 2. After that, the net formed into the head configuration was placed in position longitudinally and laterally and then superimposed on the moisture-permeable material for wigs, formed into the head configuration. After that, as in the case of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com