Method Of Disposing Of Drill Cuttings In Roads

a technology of drilling cuttings and roads, applied in the direction of adhesive types, bituminous material adhesives, constructions, etc., can solve the problems of drilling site operators' significant problems, the inability to use drill cuttings from wells within roads, and the high cost of local remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

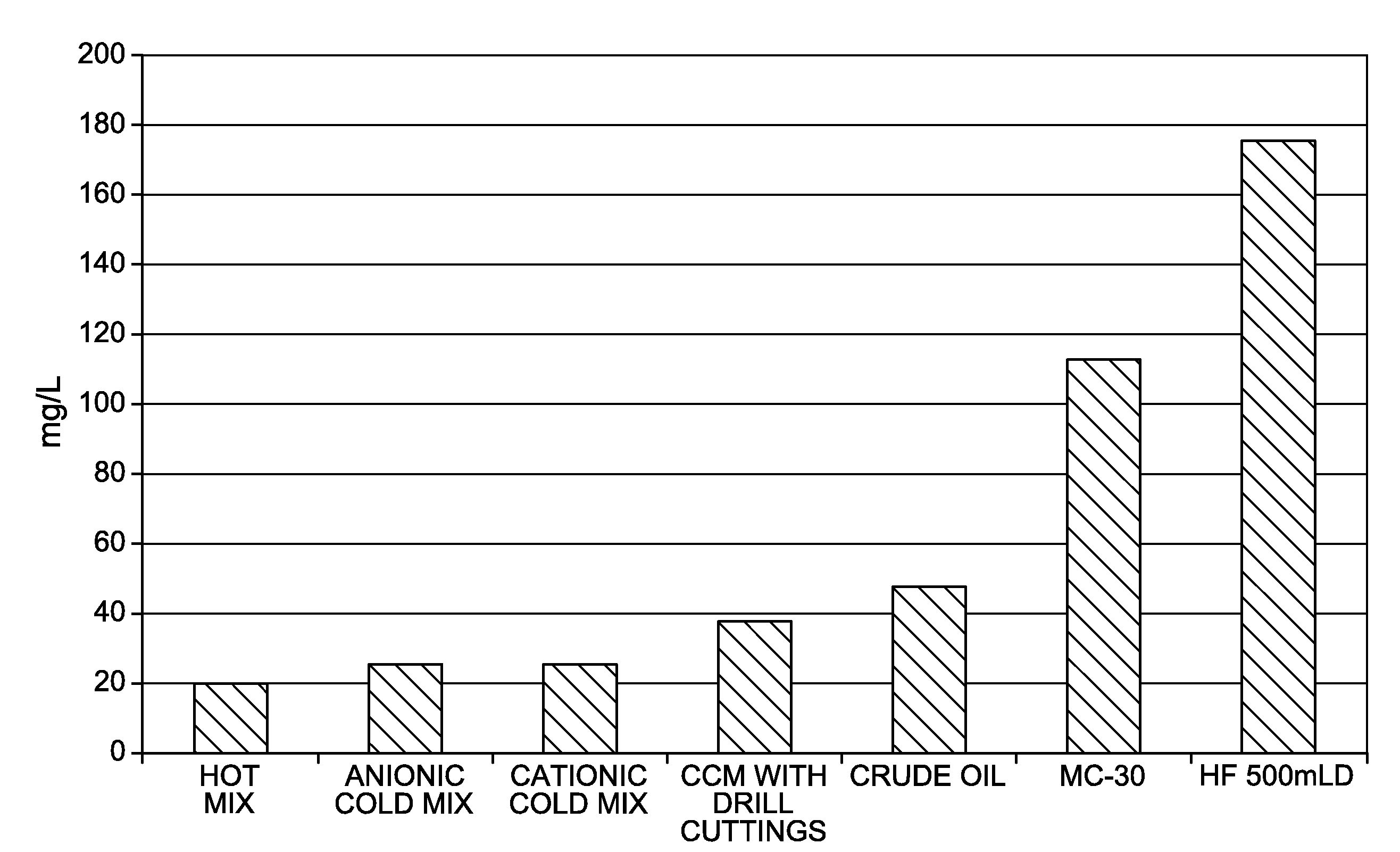

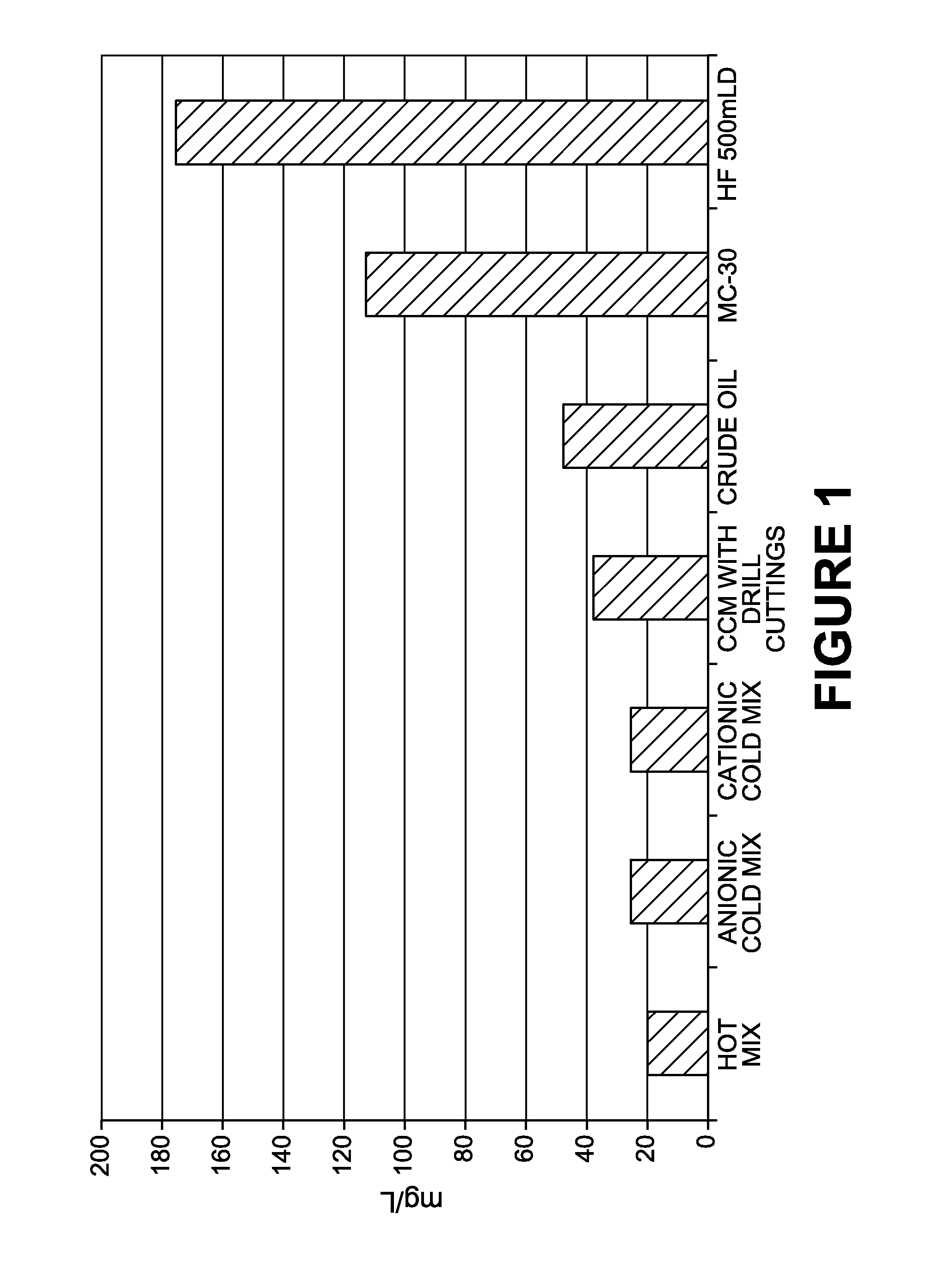

Image

Examples

first embodiment

[0026]In a first embodiment, the drill cuttings are blended with virgin aggregate to 5-25% (w / w) and asphalt binder for use as the base course of a road bed with or without a surface course. The blended drill cuttings and aggregate may be applied to the road bed in the usual manner with graders and compaction vehicles. In this embodiment, as a result of the hydrocarbon contaminants, the blended drill cuttings, aggregate and binder provide effective dust suppression when used in an unsealed road.

second embodiment

[0027]In a second embodiment, drill cuttings are blended with virgin aggregate to 5-25% (w / w) and blended with an asphalt binder such that the asphalt binder is 4-8% (w / w) of the total mass of the resulting asphalt concrete.

[0028]The blending of drill cuttings with virgin aggregate may be achieved through use of appropriate mixing equipment including reclaimers either at the road construction site, aggregate quarry or an asphalt plant.

[0029]The actual proportions of drill cuttings relative to virgin aggregate are determined through assessment of the relative amounts of and properties of the contaminants. Generally, more viscous hydrocarbon contaminants can be incorporated at a higher weight % whereas less viscous more volatile hydrocarbon contaminants are incorporated at a lower weight %. Contaminants other than hydrocarbons are encapsulated within the structure by the asphalt binder.

[0030]In a further embodiment, the drill cuttings (or a similar material such as soil, sand or other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com