Asphalt shingle roof waterproof system of sloping roof high-rise building and construction method of asphalt shingle roof waterproof system

A high-rise building and asphalt tile technology, which is applied to the asphalt tile roof waterproof system of high-rise buildings with sloped roofs and its construction field, can solve the problems of waterproof layer damage, glass fiber tile tensile cracks, poor flexibility of asphalt tiles, etc., and achieve reasonable construction steps , Solve the waterproof problem, the effect of firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

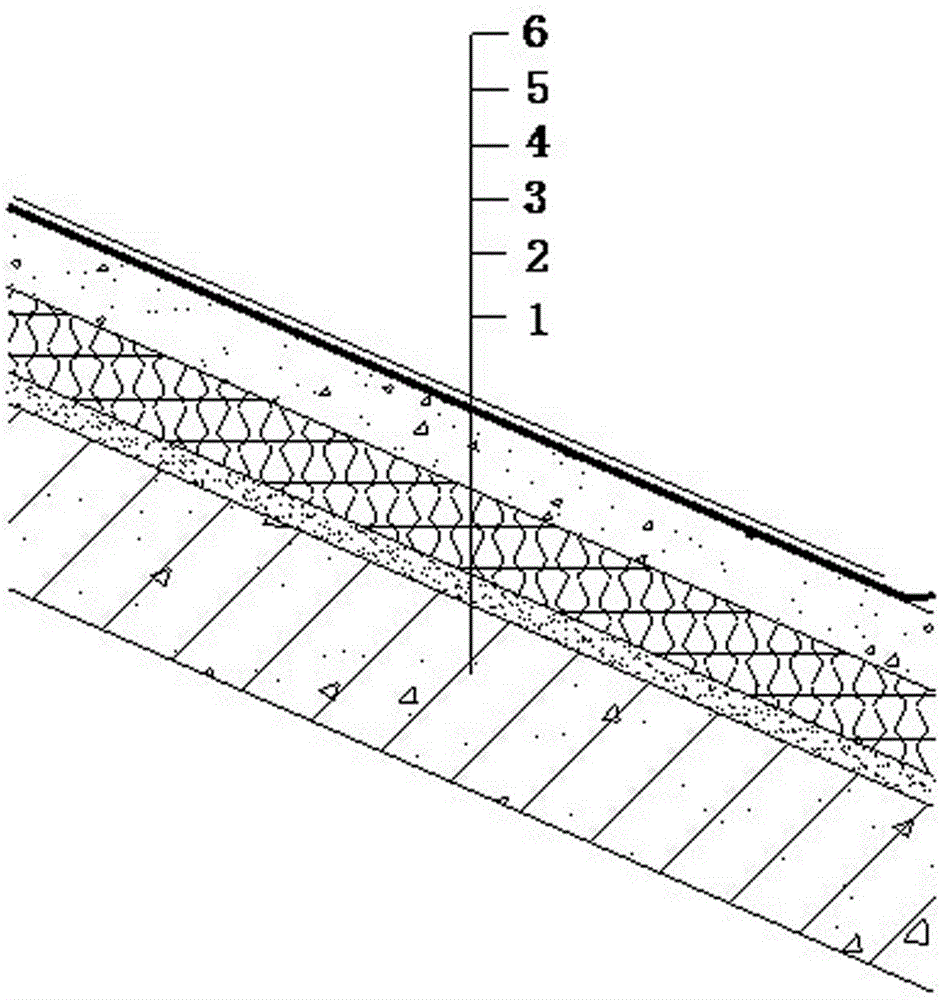

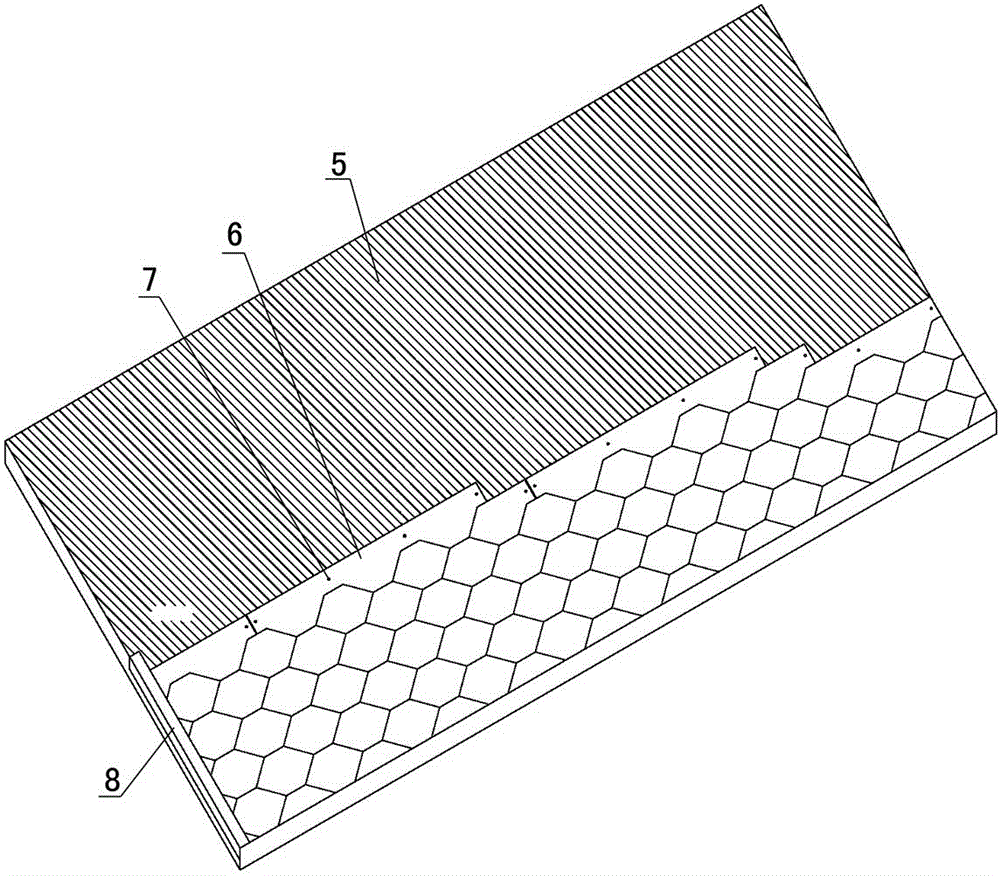

[0049] like Figure 1-3 As shown, the asphalt tile roof waterproof system for high-rise buildings with inclined roofs, from bottom to top, is reinforced concrete floor 1, mortar leveling layer 2, insulation layer 3, concrete base layer 4, double-sided self-adhesive waterproof membrane layer 5 and asphalt tiles 6, and aluminum gussets 8 are provided on both sides of the roof.

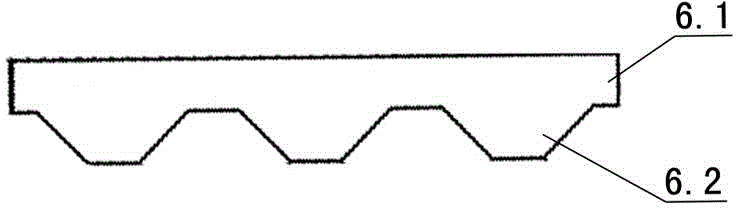

[0050] The upper half of the asphalt tile 6 is a rectangular tile skirt 6.1, the lower half of the asphalt tile 6 is three to four inverted trapezoidal vertical pieces 6.2, and the asphalt tile 6 is glued to the double-sided self-adhesive waterproof membrane layer 5. It is also connected with the double-sided self-adhesive waterproof coiled material layer 5 and the concrete base 4 through the nail 7 nailed on the tile skirt 6.1 between two adjacent vertical pieces 6.2.

[0051] Between the upper and lower adjacent asphalt tiles, the vertical piece 6.2 of the upper side asphalt tile is pressed on the til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com