Fuel cell heater

a fuel cell and heater technology, applied in the field of heaters, can solve the problems of insufficient primary heat output of discarded heat, insufficient electrical wattage of conventional fuel cell generators, and inconvenient use of fuel cell electrical output to augment the rejected heat by resistive heating, etc., to achieve better and more advantageous overall results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

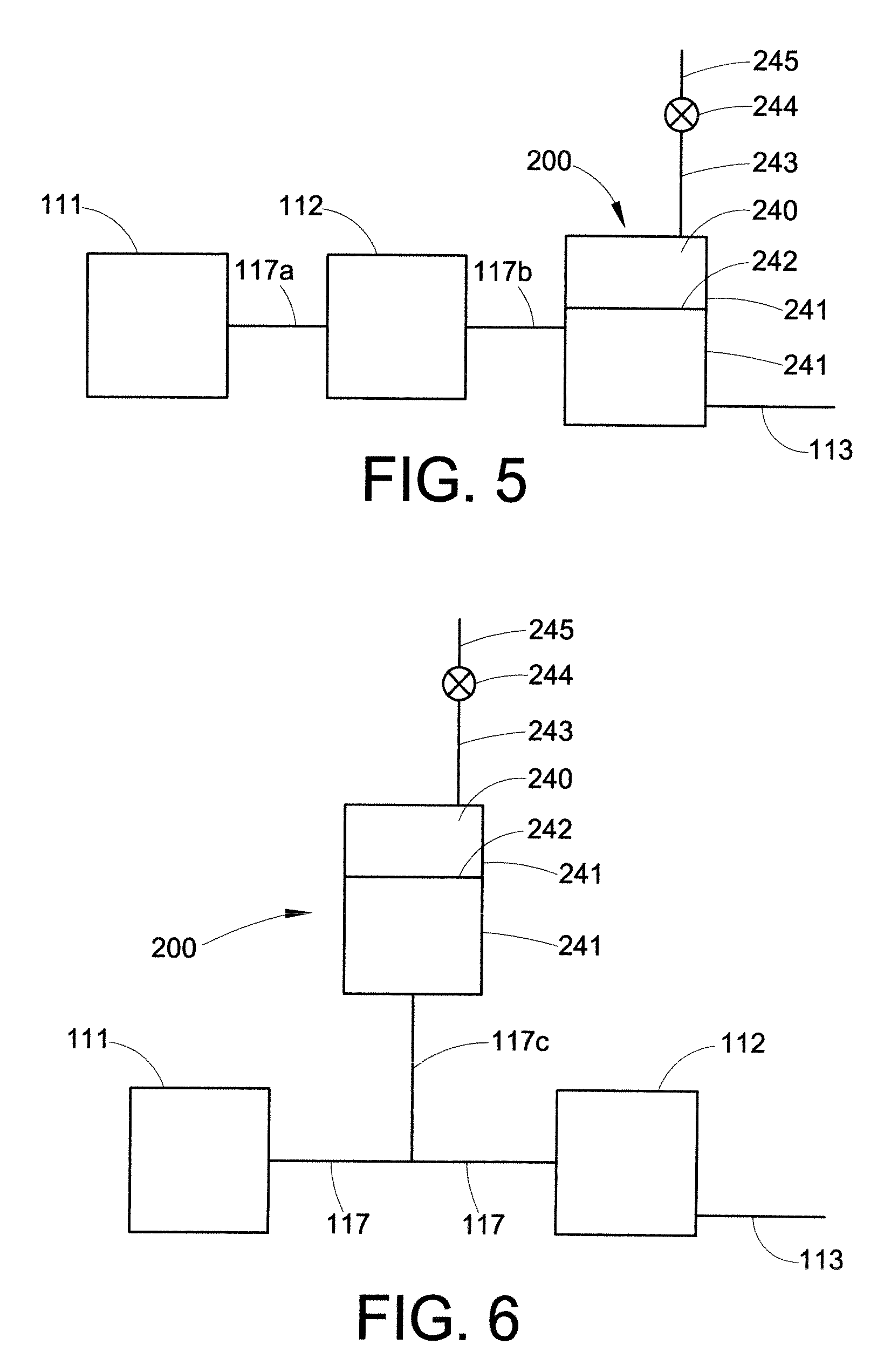

[0045]It should, of course, be understood that the description and drawings herein are merely illustrative and that various modifications and changes can be made in the structures disclosed without departing from this disclosure. Like numerals refer to like parts throughout the several views. It will also be appreciated that the various identified components of the space heater disclosed herein are merely terms of art that may vary from one manufacturer to another and should not be deemed to limit the present disclosure.

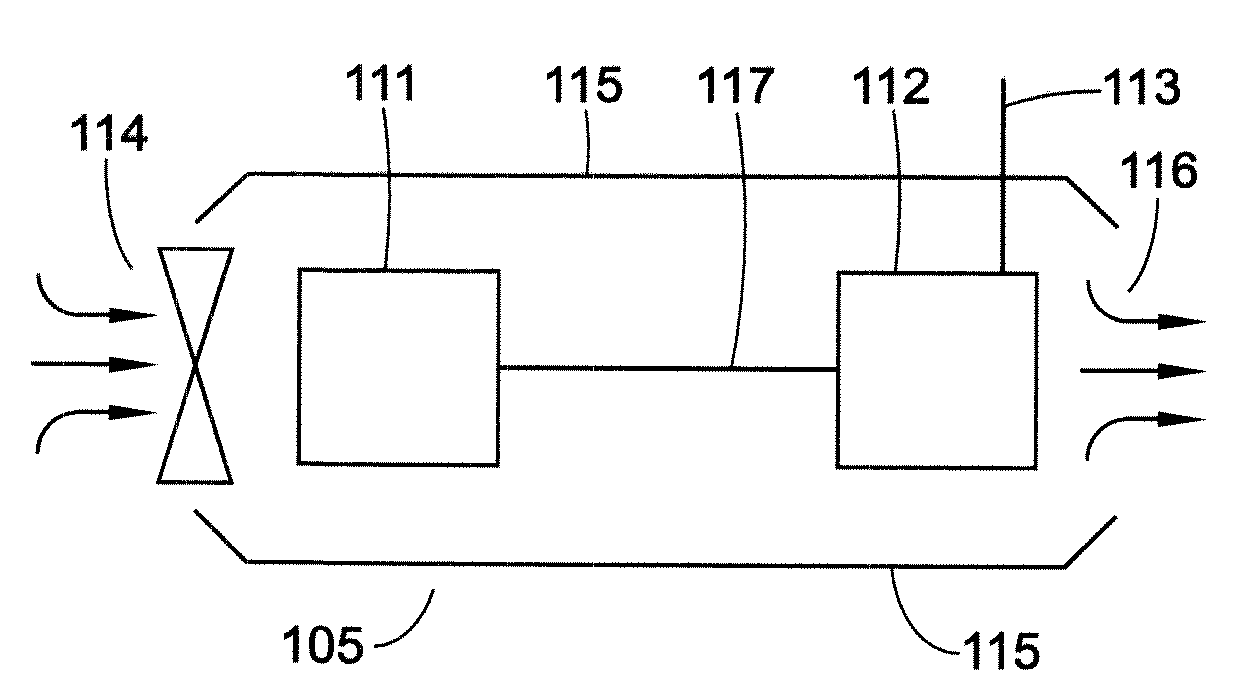

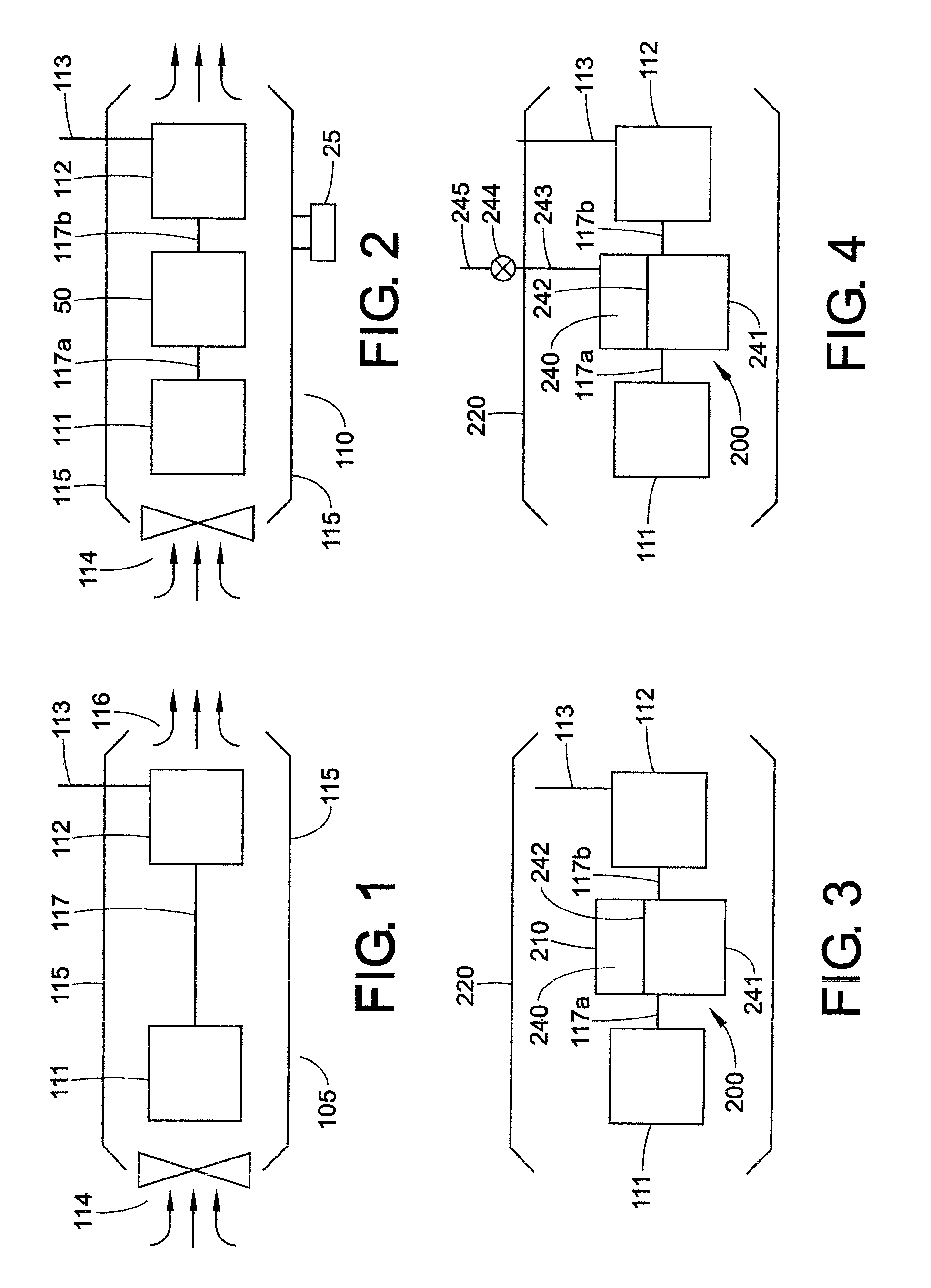

[0046]With reference to FIG. 1, a schematic of a conventional fuel fired, hot air space heater 105 is illustrated. The heater is the type which that would operate on externally supplied electrical power from a local power grid or a generator. The heater 105 includes an enclosure 115 for housing a burner 111 operably connected to a heat exchanger 112. A fan 114 is provided at an inlet of the enclosure for generating air flow through the enclosure. The enclosure 115 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com