Heavy-duty plastic bag with easy tear corner spout portion

a plastic bag and corner spout technology, applied in the field of heavy-duty plastic bags, can solve the problems of relative difficulty in hand tear, spillage of some contents, and difficulty in pouring contents, and achieve the effect of improving pouring tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

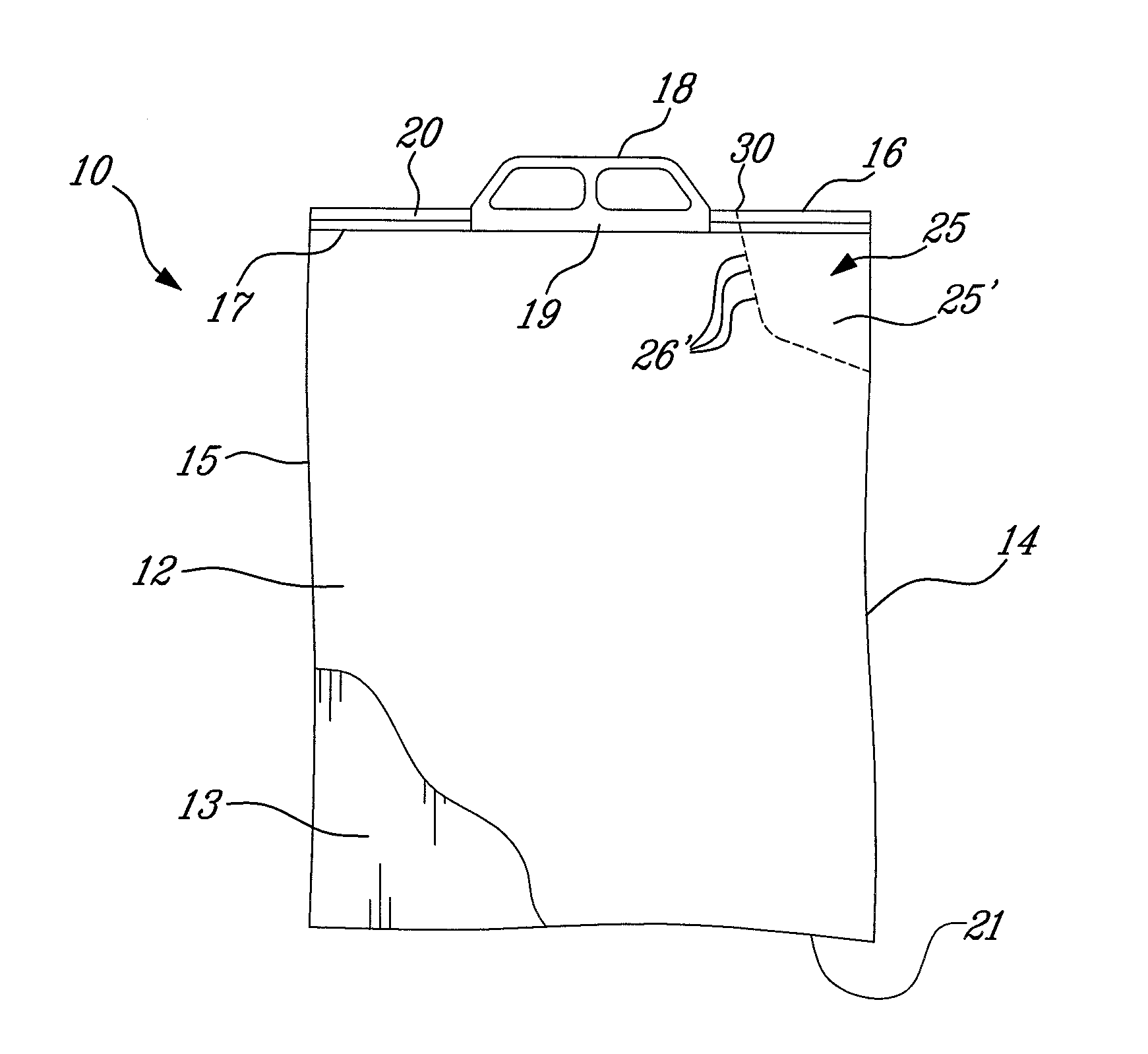

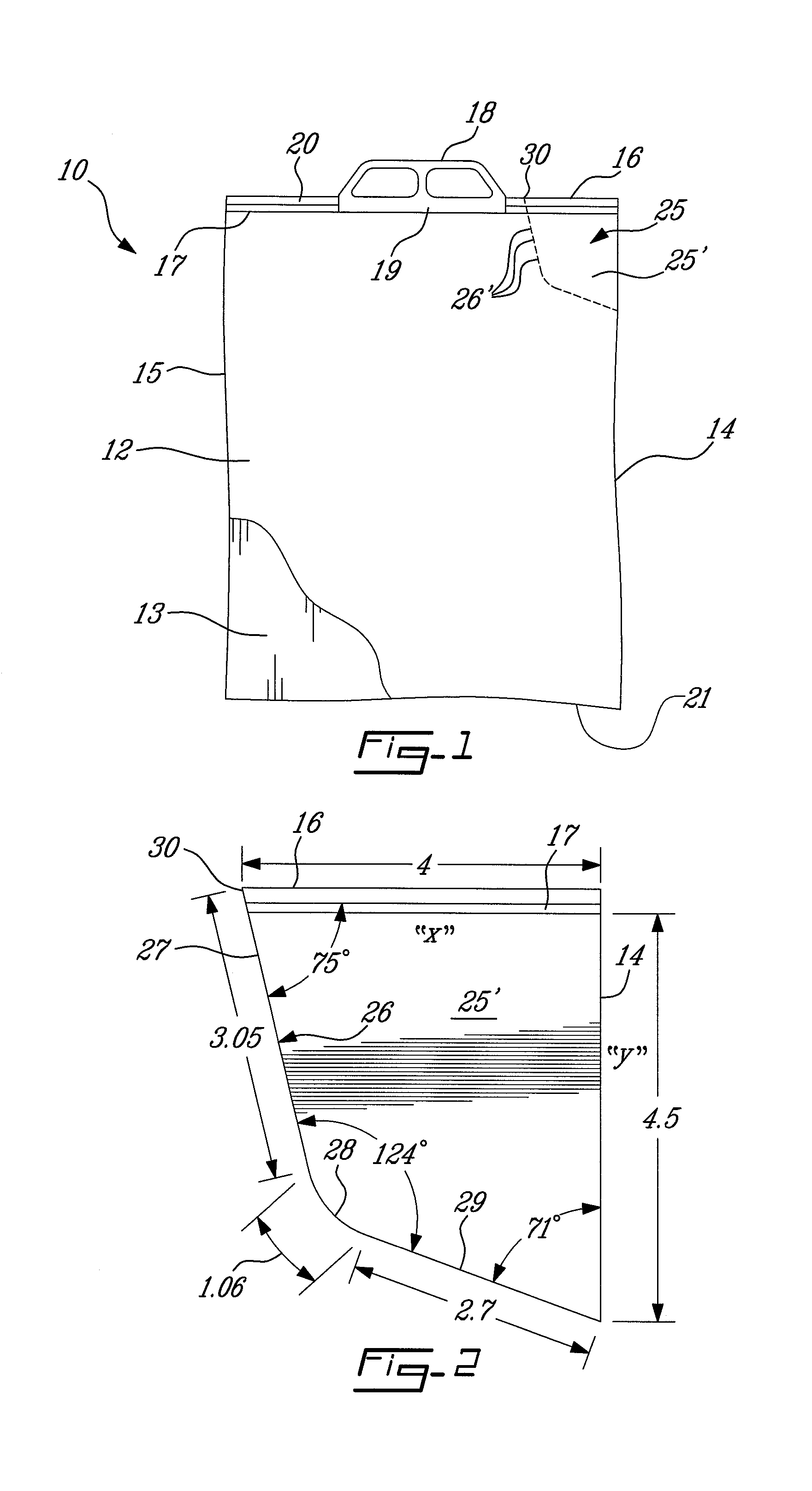

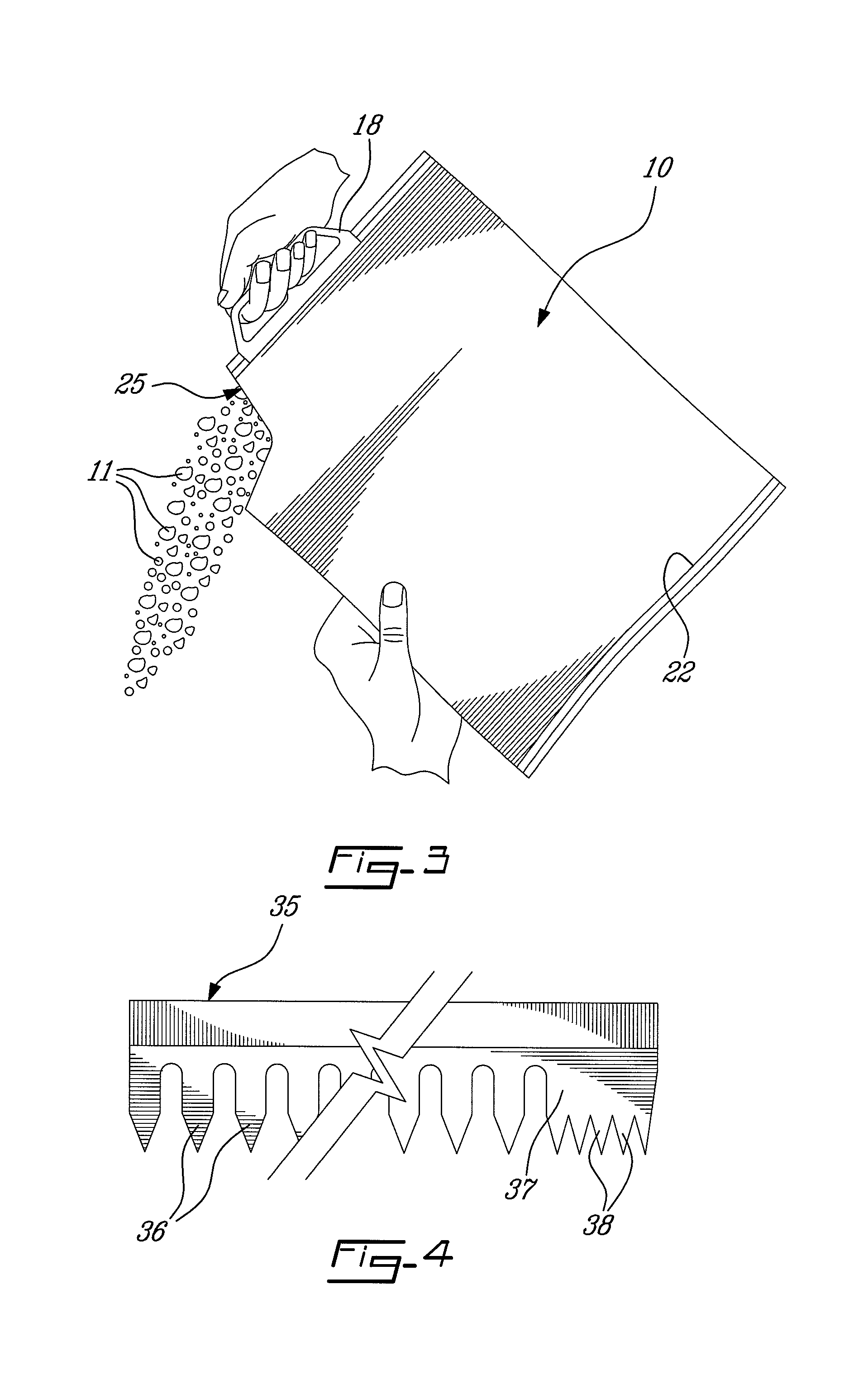

[0018]Referring now to FIGS. 1 to 3 there is shown generally at 10, the heavy-duty plastic bag of the present invention and particularly adapted to contain a granular product 11, see FIG. 3, therein such as coarse salt pellets, fertilizers, sand, pet food, yeast, lawn and garden products, small stones and similar products. Typically, this bag is formed from polyolefin film material which may be comprised of one of high density, low density or linear low density polyethylene, polypropylene or mixtures thereof. The bag 10 of the present invention is adapted to contain loads of from about 25 lbs to 40 lbs or more of granular products of the above-mentioned type. The bag when fabricated to contain about 40 lbs of granular products, typically has a width of approximately 15 inches and a length of approximately 24 inches.

[0019]The heavy-duty plastic bag 10 is conveniently formed from such film material in tubular form and as herein illustrated it defines a front wall 12, a rear wall 13 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com