Bur for Adjustable Tool Drive Arrangement

a technology of drive arrangement and adjustable tool, which is applied in the direction of boring tools, turning tools, dental tools, etc., can solve the problems of time-consuming and cost-intensive, not designed to allow for length adjustment of tools, and repeated tool changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

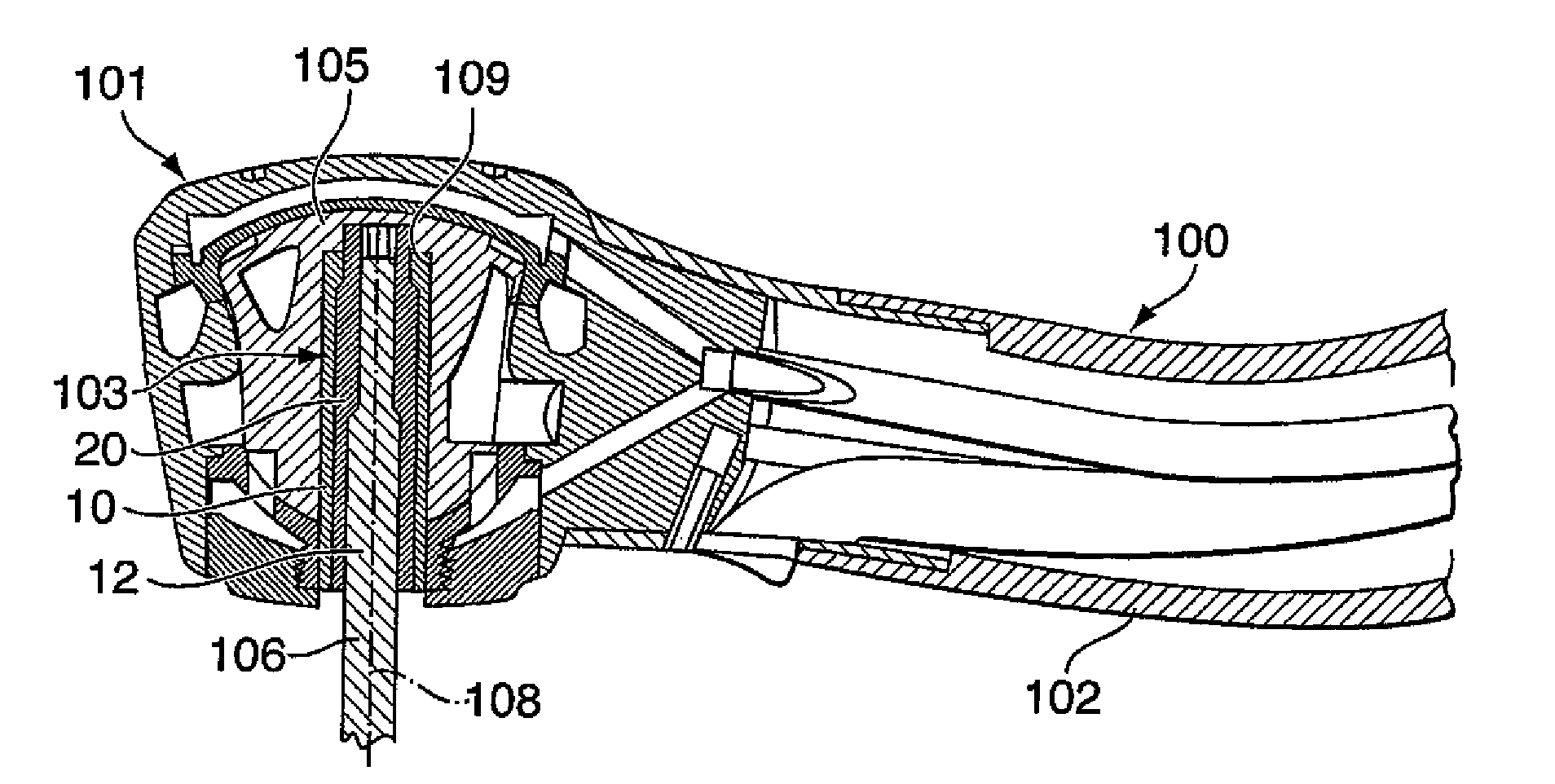

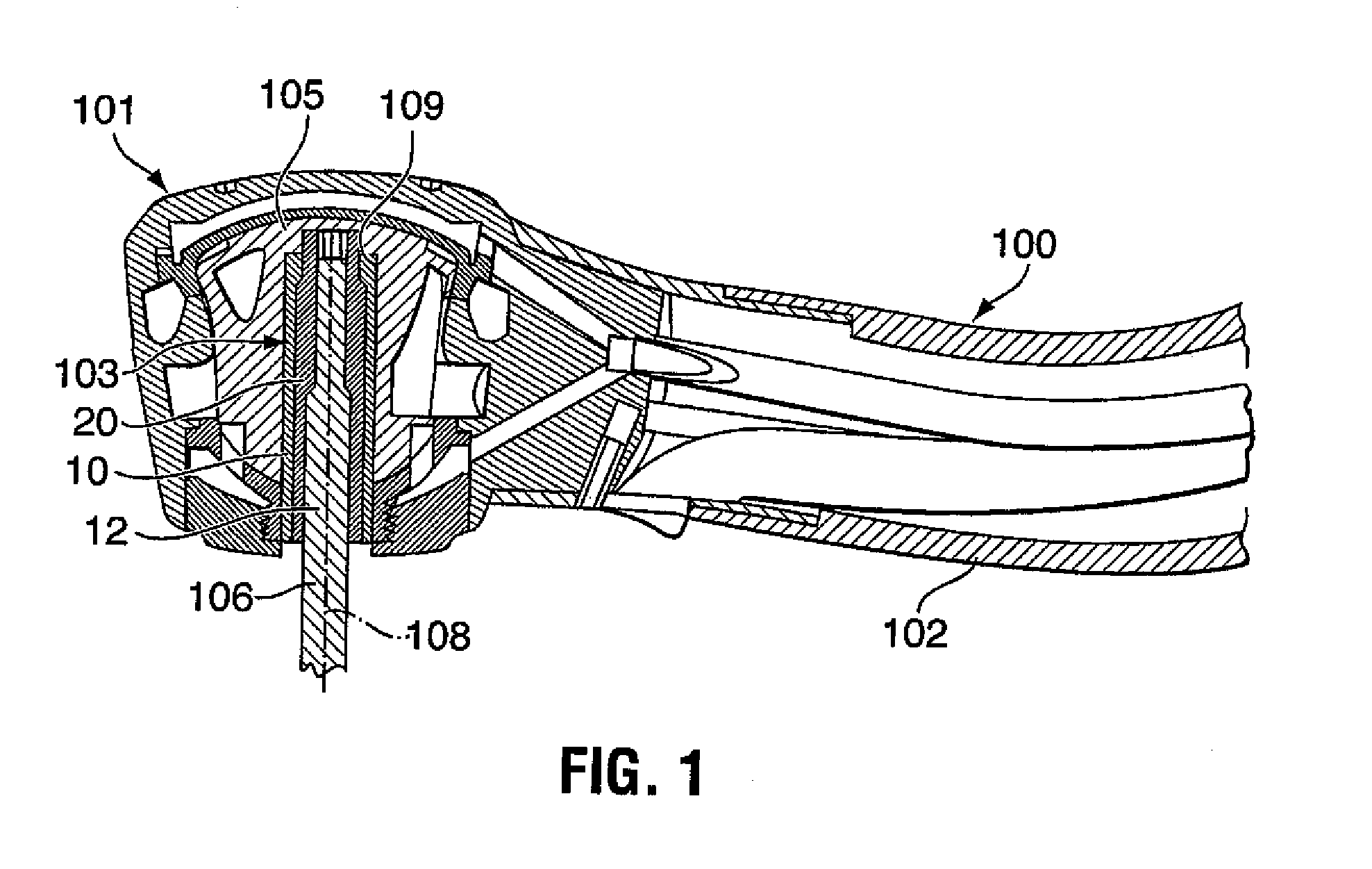

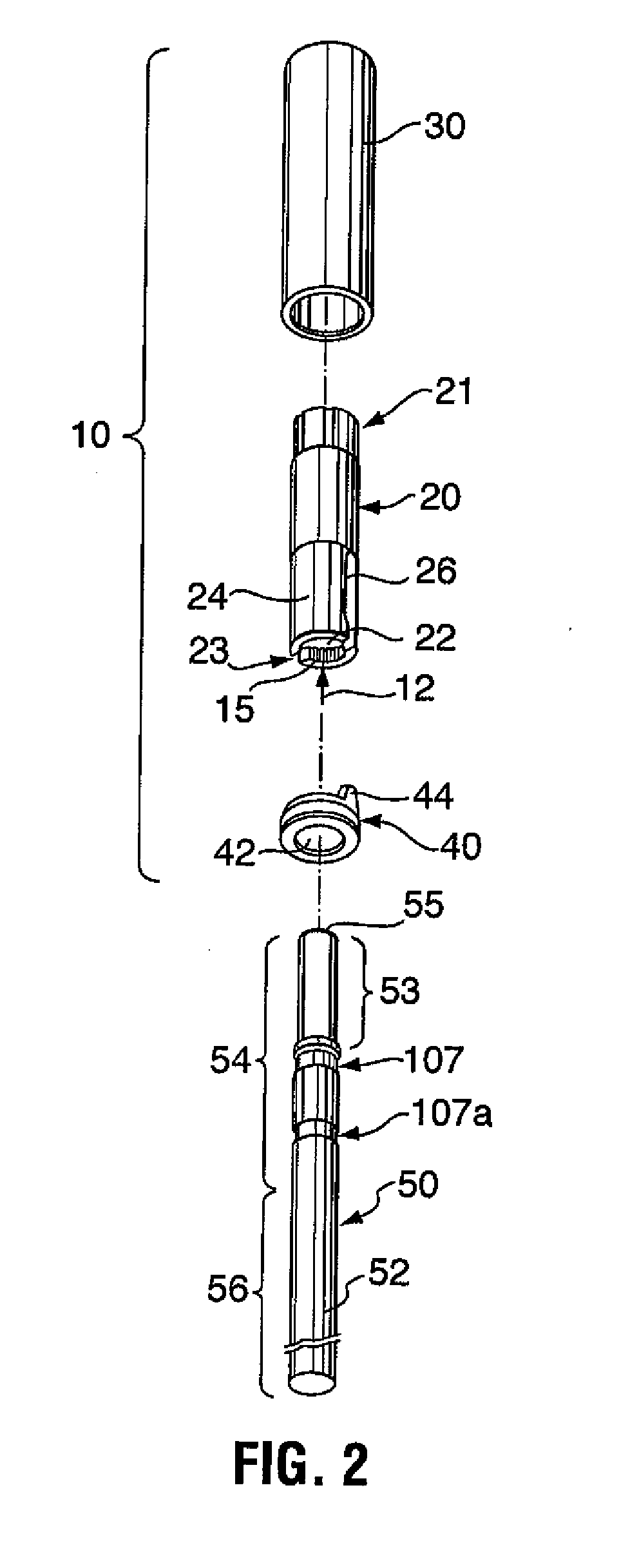

[0045]Generally, the present invention provides a tool drive arrangement for a handpiece with a drive head, the tool drive arrangement permitting length adjustment of a tool in the drive head by concentrically supporting the tool in the drive head at any position from a fully inserted position to a maximum retracted position.

[0046]In one embodiment, the invention provides a tool drive assembly including the tool drive arrangement, a rotatable tool and a rotatable tool supporting element for concentrically supporting the tool from the fully inserted position to the maximum retracted position. The tool preferably includes a maximum retraction indicator for indicating to a user when the tool has been retracted to the maximum retraction position. This provides a significant advantage over the prior art by allowing a user to adjust the exposed length of a rotatable tool, preferably a dental bur, without exceeding safe operating limits.

[0047]More particularly, the rotatable tool drive ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com