Process for producing ham without resting periods for curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

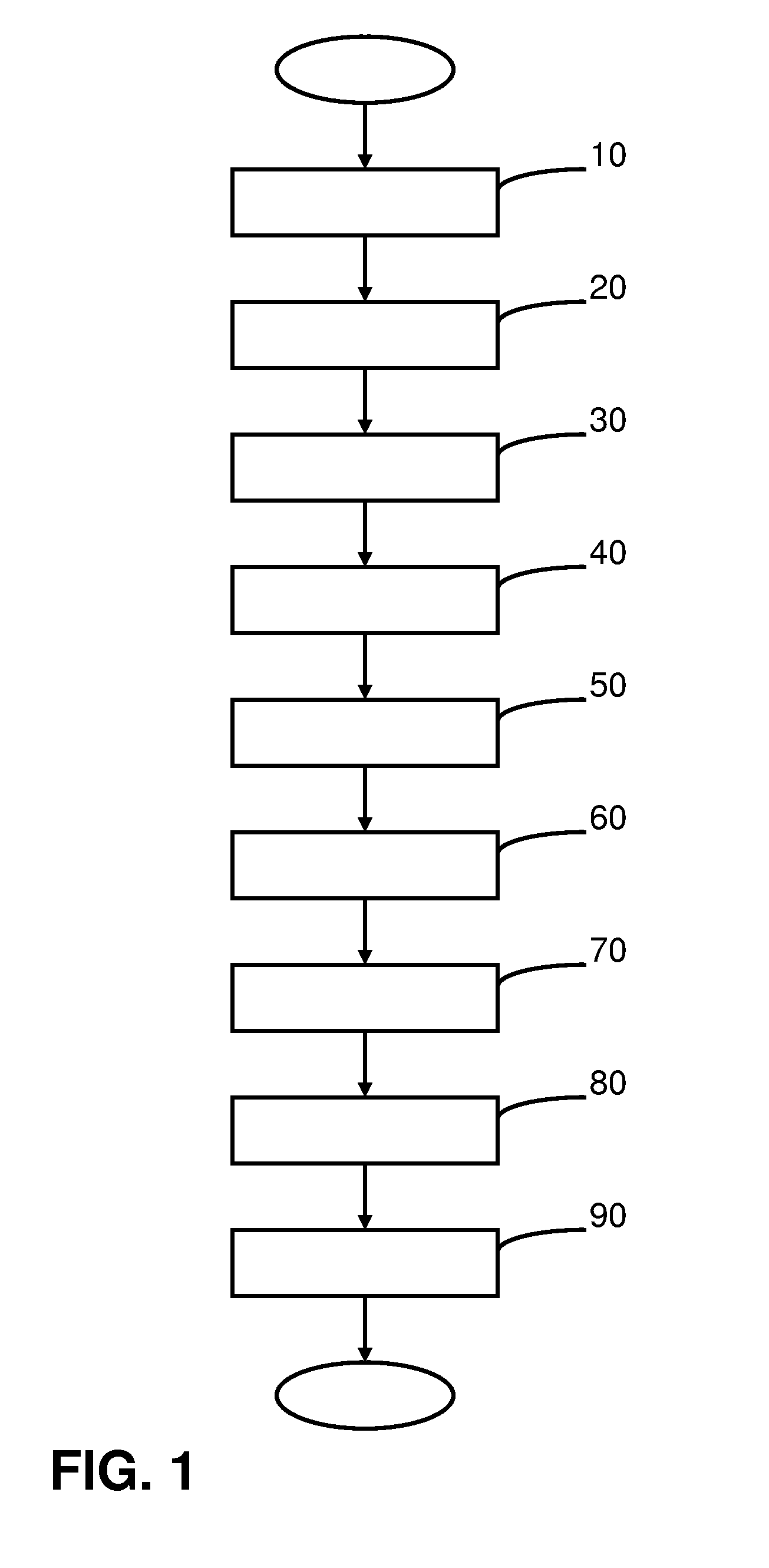

Method used

Image

Examples

example of embodiment

of the Invention

[0031]The invention will now be described with respect to the following example, which is solely for the purpose of representing the embodiment of the principles of the invention. The following example shows the comparison of a control sample and a sample according to the invention, which is not intended to be an exhaustive representation of the invention, nor intends to limit the scope of this invention.

Preparation of the Control Sample

[0032]A portion of virginia-type ham of 4,000 kg of turkey meat is produced according to the procedure of the current state-of-the-art.

[0033]After cleaning, the turkey meat is injected with a brine preparation in an amount of about 86% in weight of said turkey meat, where the brine preparation was prepared for 45 minutes. The injection of the brine composition along with the softening of the pieces of turkey meat was carried out during a period of 50 minutes.

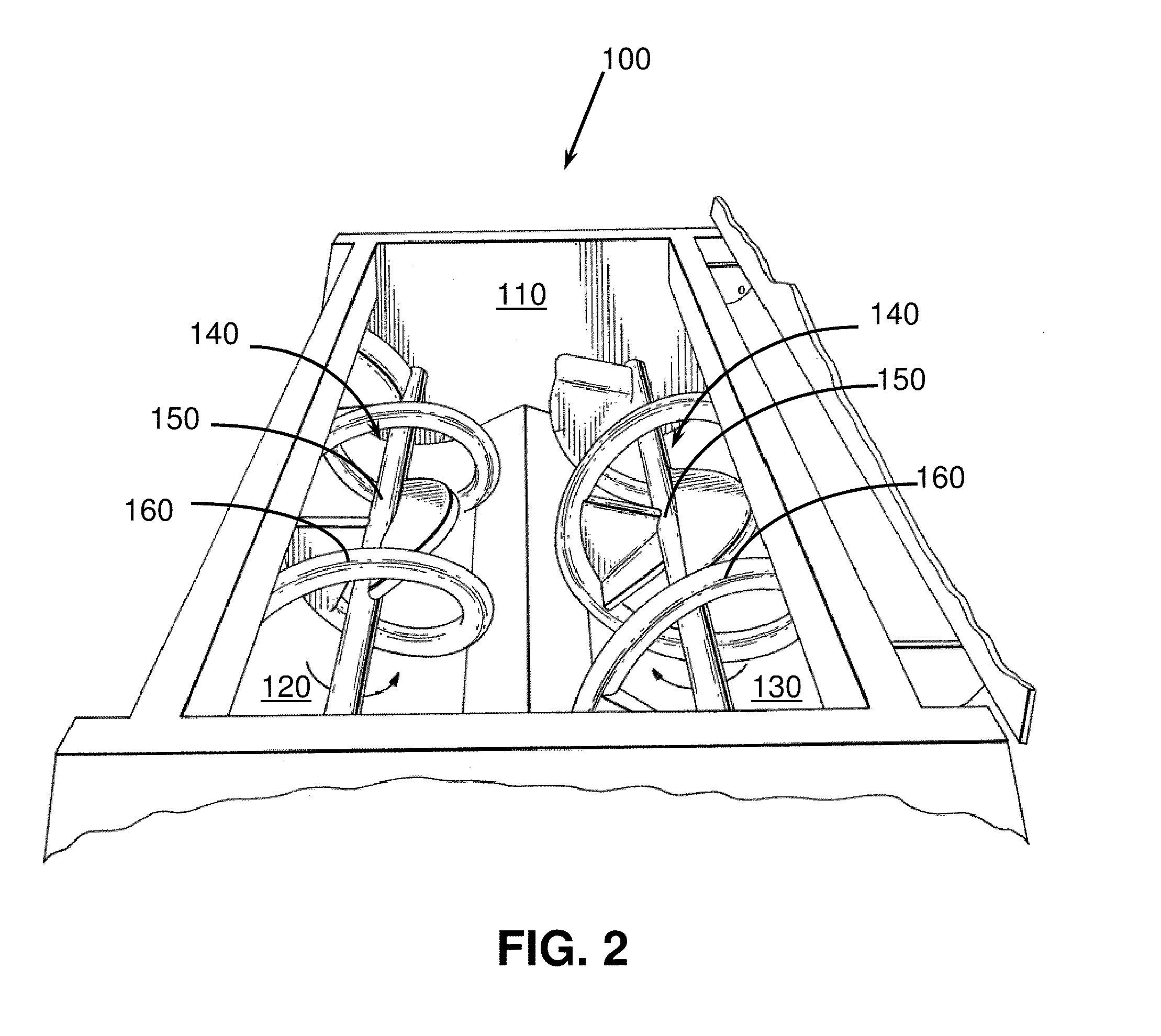

[0034]The pieces of turkey meat are then submitted to a massage in a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com