Outer-wall construction apparatus for building

a construction apparatus and outer wall technology, applied in mechanical devices, threaded fasteners, nuts, etc., can solve the problems of difficult to maintain, difficult to work, and difficult to handle stone or metal plate structures, and achieve the effects of convenient construction, high utility, and enhanced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

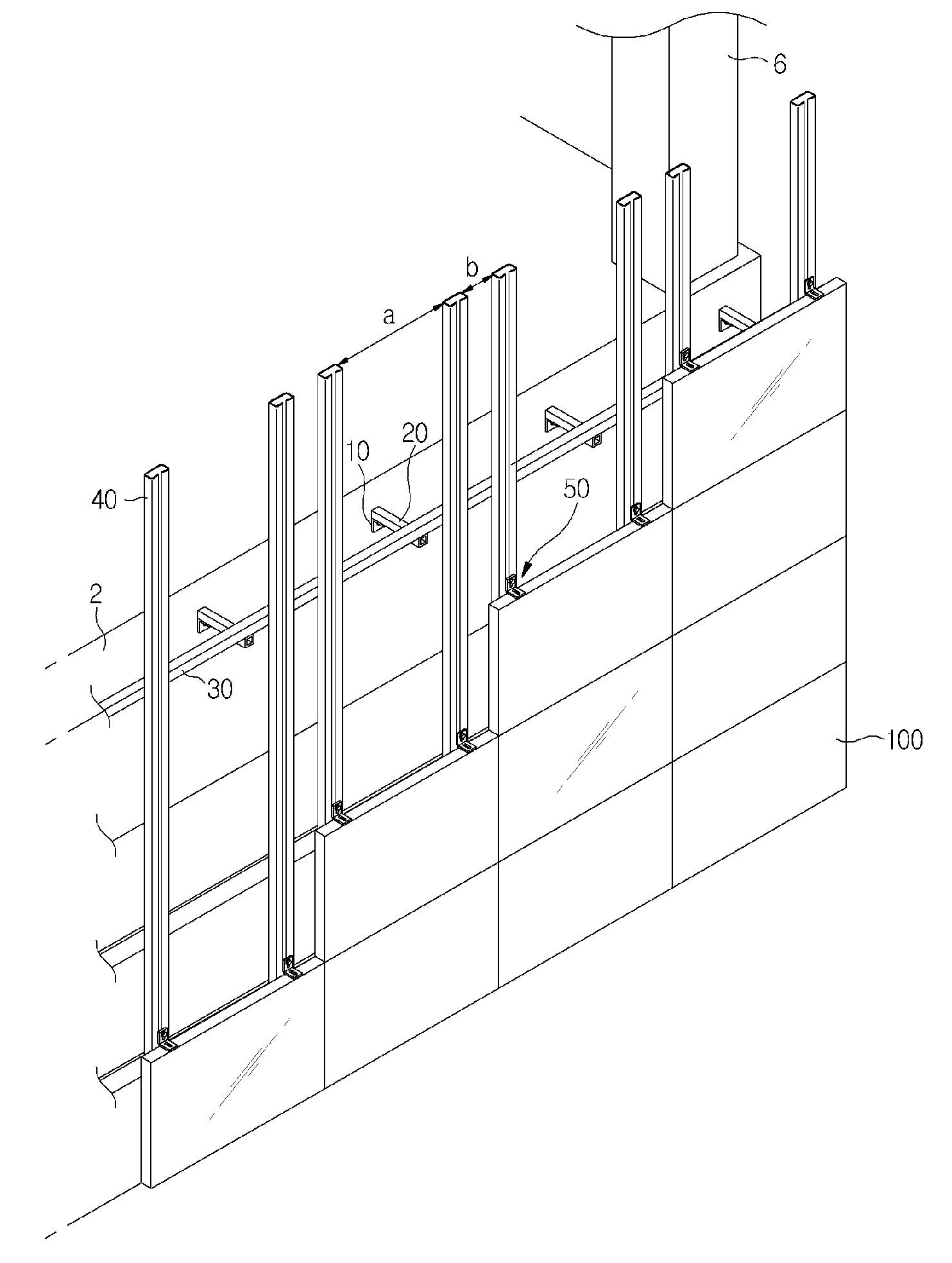

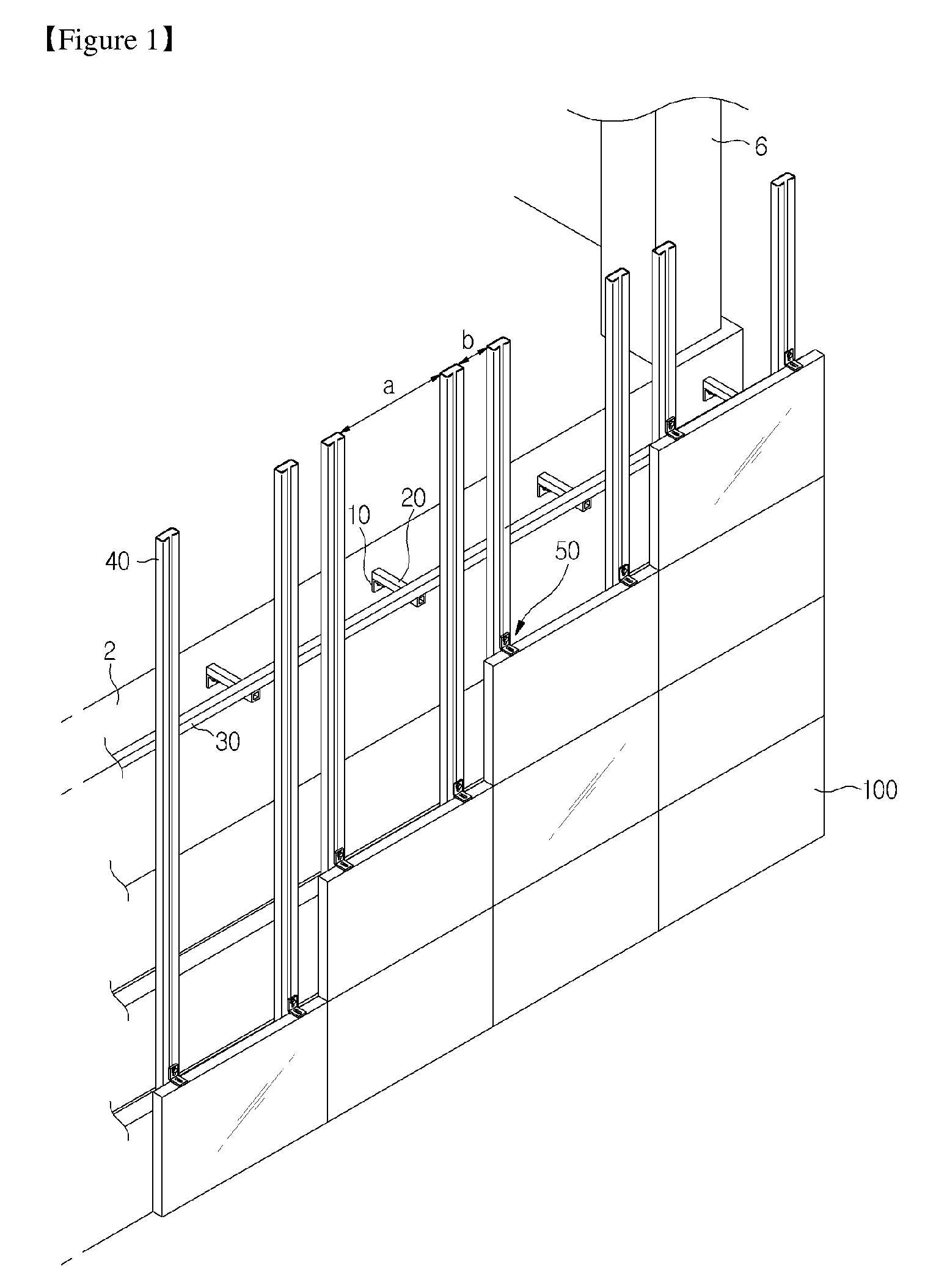

[0022]FIG. 1 is a procedural perspective view that shows a figure of constructing outer wall of a building using an outer wall construction apparatus in accordance with the present invention.

[0023]Before full description, as shown in the drawing, the objective building of which the outer wall is constructed through an outer wall construction apparatus in accordance with the present invention can be in shape that floor and slab 2 of ceilings for each floor and pillar 6 except outer wall are provided, and the slab 2 and pillar 6 can be steel frame using H beam or concrete structure, etc.

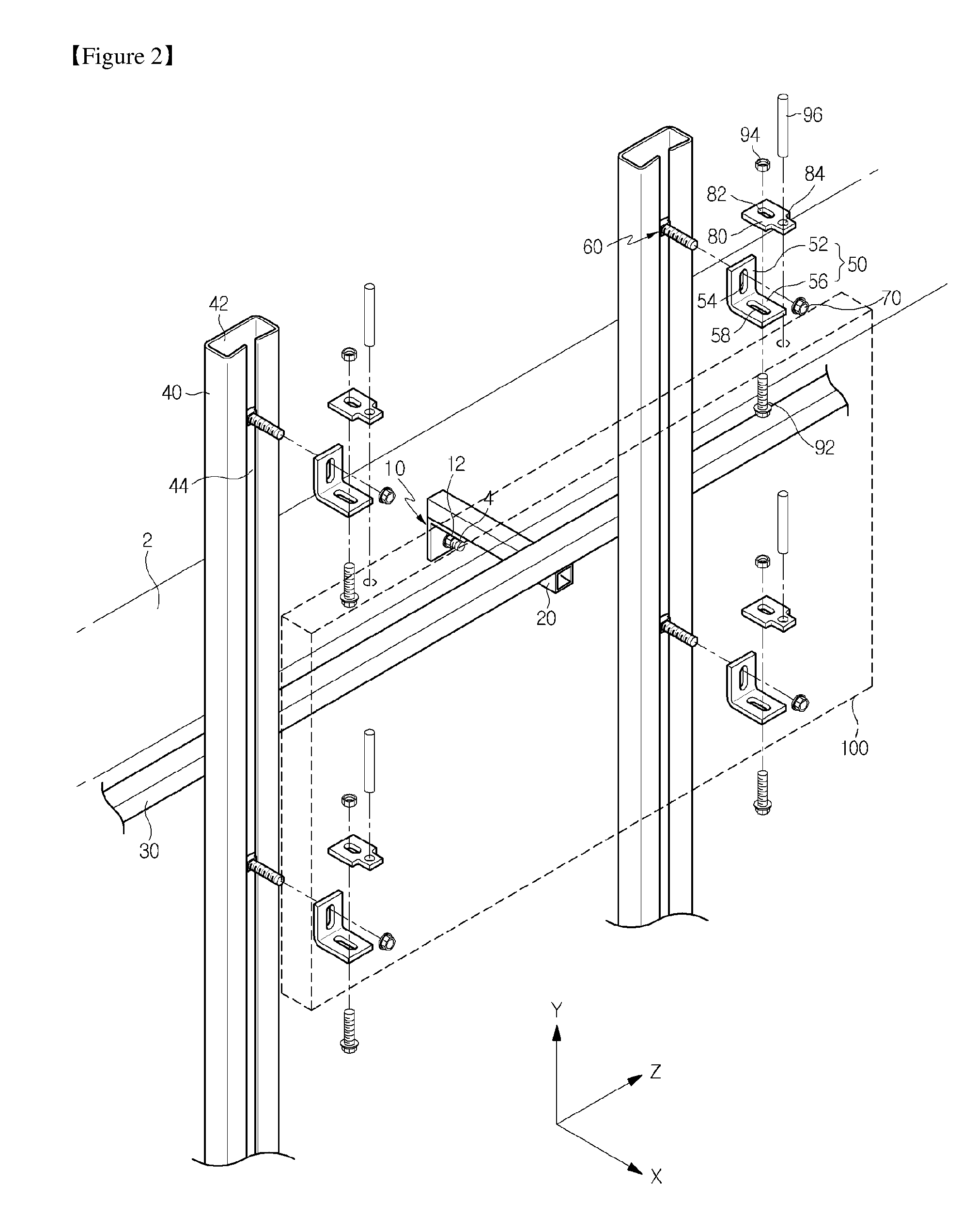

[0024]And an outer wall construction apparatus in accordance with the present invention for constructing outer wall for such a building with plate structure such as stone has basic structure that includes first bracket 10 fixed to the side of slab 2 of each floor, a plurality of fixation bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com