Photoreceptor for electrophotography

a photoreceptor and electrophotography technology, applied in the field of photoreceptors for electrophotography, can solve the problems of difficult production conditions, poor durability, and prone to selenium crystallization with heat or mechanical impact, and achieve the effects of not impairing the basic performance of electrophotography, good stability to repeated use, and small change in charge potential and residual potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

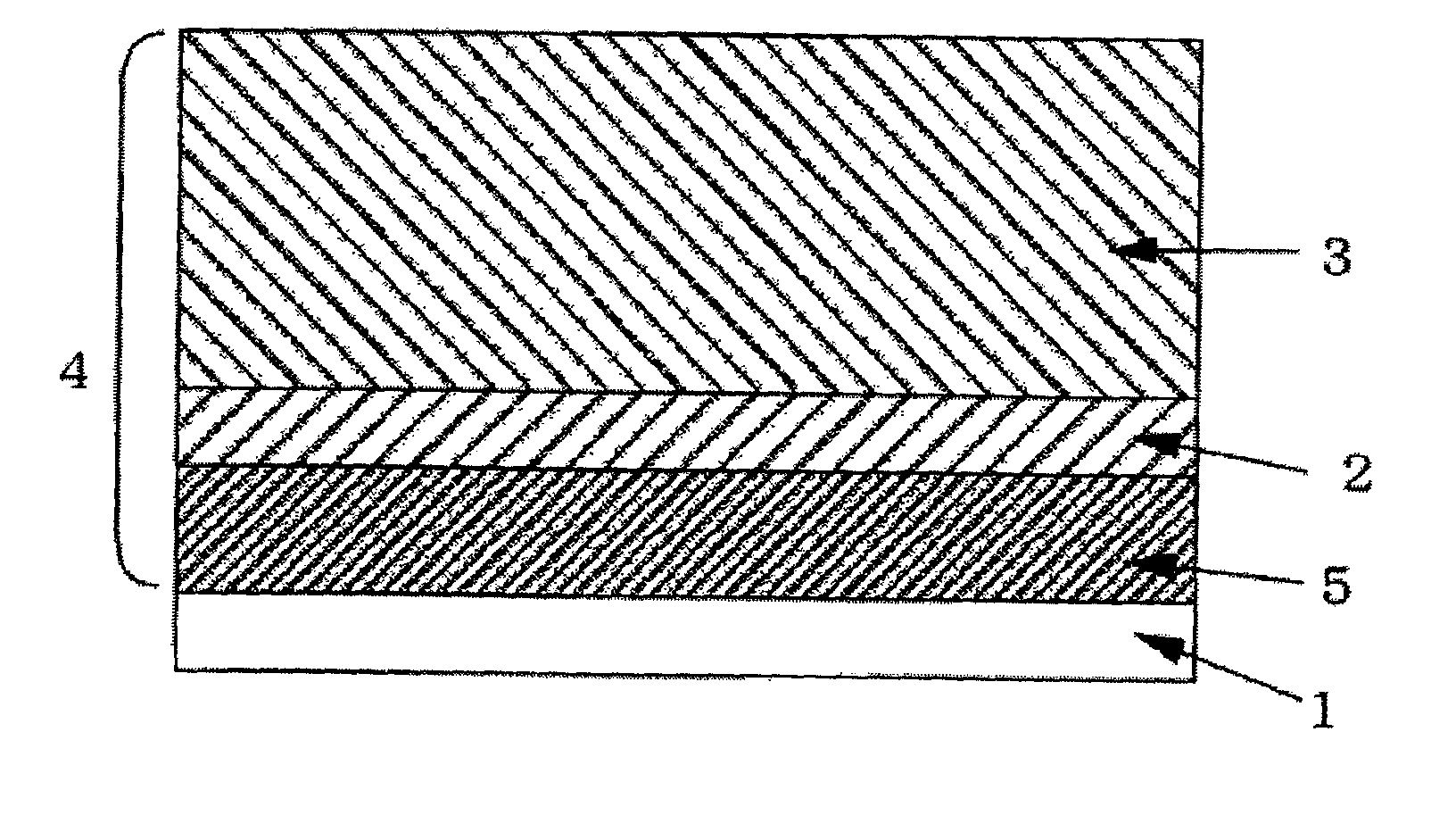

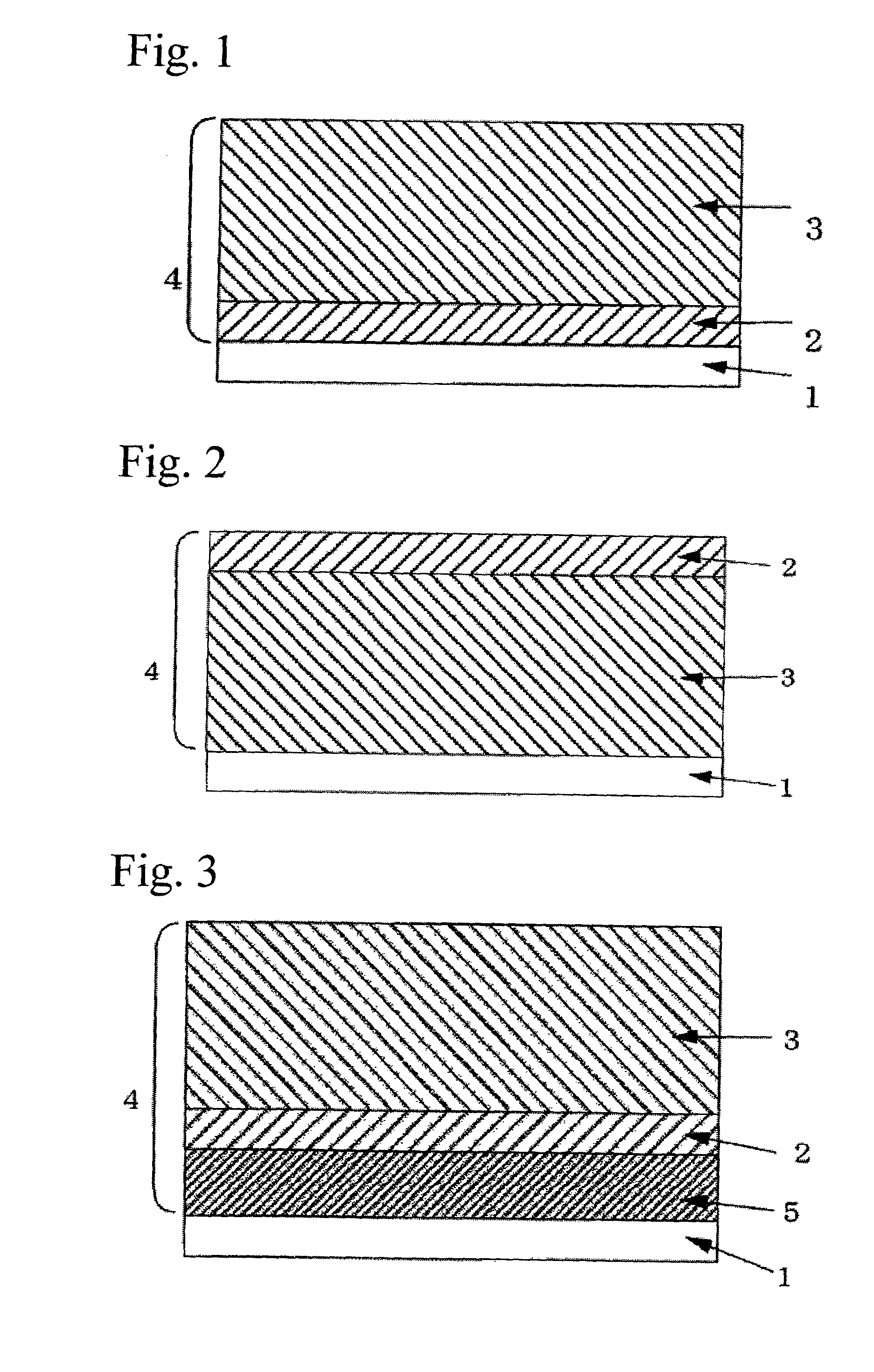

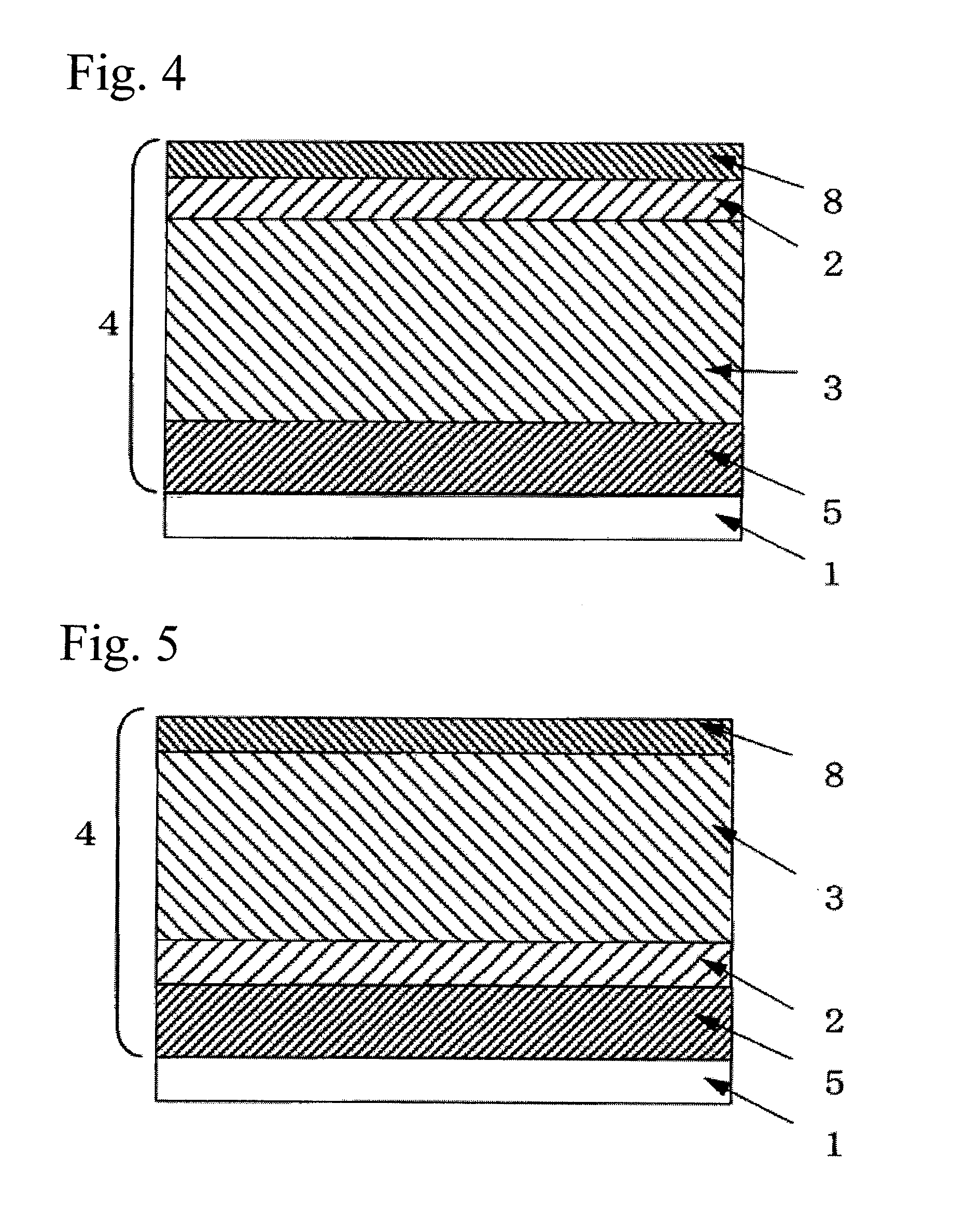

Image

Examples

example 1

[0091]In 13 parts of methanol was dissolved 1 part of an alcohol-soluble polyamide (Amilan CM-4000, manufactured by Toray Industries, Inc.). Thereto was added 5 parts of titanium oxide (Tipaque CR-EL, manufactured by Ishihara Sangyo Kaisha, Ltd.). The resultant mixture was treated with a paint shaker for 8 hours to disperse the titanium oxide and thereby produce a coating fluid for undercoat layer formation. Thereafter, the coating fluid was applied with a wire-wound bar to the aluminum side of a PET film having a vapor-deposited aluminum coating, and then dried to form an undercoat layer having a thickness of 1 μm.

[0092]Subsequently, 1.5 parts of titanylphthalocyanine oxide having a Cu-Kα X-ray diffraction spectrum having an intense peak at diffraction angles 2θ±0.2° of 7.5, 10.3, 12.6, 22.5, 24.3, 25.4, and 28.6 (charge-generating agent No. 1)

was added to 50 parts of a 3% cyclohexanone solution of a poly(vinyl butyral) resin (S-LEC BL-S, manufactured by Sekisui Chemical Co., Ltd.)...

example 2

[0097]A photoreceptor was produced in the same manner as in Example 1, except that titanylphthalocyanine oxide giving a Cu-Kα X-ray diffraction spectrum having an intense peak at diffraction angles 2θ±0.2° of 9.6, 24.1, and 27.2 (charge-generating agent No. 2) was used in place of the charge-generating agent No. 1 and that the following p-terphenyl compound (charge-transporting agent No. 2)

was used as a charge-transporting agent in place of the benzidine compound (charge-transporting agent No. 1).

example 3

[0100]Ten parts of an alcohol-soluble polyamide (Amilan CM-8000, manufactured by Toray Industries, Inc.) was dissolved in 190 parts of methanol. The resultant solution was applied with a wire-wound bar to the aluminum side of a PET film having a vapor-deposited aluminum coating, and then dried to form an undercoat layer having a thickness of 1 μm.

[0101]Subsequently, 1.5 parts of the following r-form metal-free phthalocyanine as a charge-generating agent (charge-generating agent No. 3)

was added to 50 parts of a 3% cyclohexanone solution of a poly(vinyl butyral) resin (S-LEC BL-S, manufactured by Sekisui Chemical Co., Ltd.). The resultant mixture was treated with an ultrasonic disperser for 1 hour to disperse the charge-generating agent. The dispersion obtained was applied to the undercoat layer with a wire-wound bar and then dried at 110° C. and ordinary pressure for 1 hour to form a charge-generating layer having a thickness of 0.6 μm.

[0102]On the other hand, 0.1 part of cyclic phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com