Core-shell structure metal nanoparticles and its manufacturing method thereof

a core-shell structure and metal nanoparticle technology, applied in the direction of cable/conductor manufacturing, non-conductive materials with dispersed conductive materials, inks, etc., can solve the problems of high cost, limited synthesizing small-sized metal nanoparticles of 30 nm or less, and high cost, so as to prevent oxidization of copper and increase copper content , the effect of economical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0067]Oleylamine 100 g, copper acetylacetonate(C5H7CuO2) 7 g and ascorbic acid 5 g were put into a round flask equipped with a condenser and heated to 70° C. for 1 hour. After then, the temperature was raised to 250° C. by a rate of 5° C. / min, and the reaction solution was reacted for 30 min at 250° C. After the reaction solution was cooled to 150° C. by air-cooling, 2 g of Ag dodecanate was added and then the temperature was raised to 250° C. by a rate of 5° C. / min, and the reaction solution was reacted for 30 min at 230° C. After the reaction completed, 300 ml of methanol was added and the nanoparticles were precipitated. These precipitates were washed with methanol more than 3 times and dried at 45° C. in a drying oven.

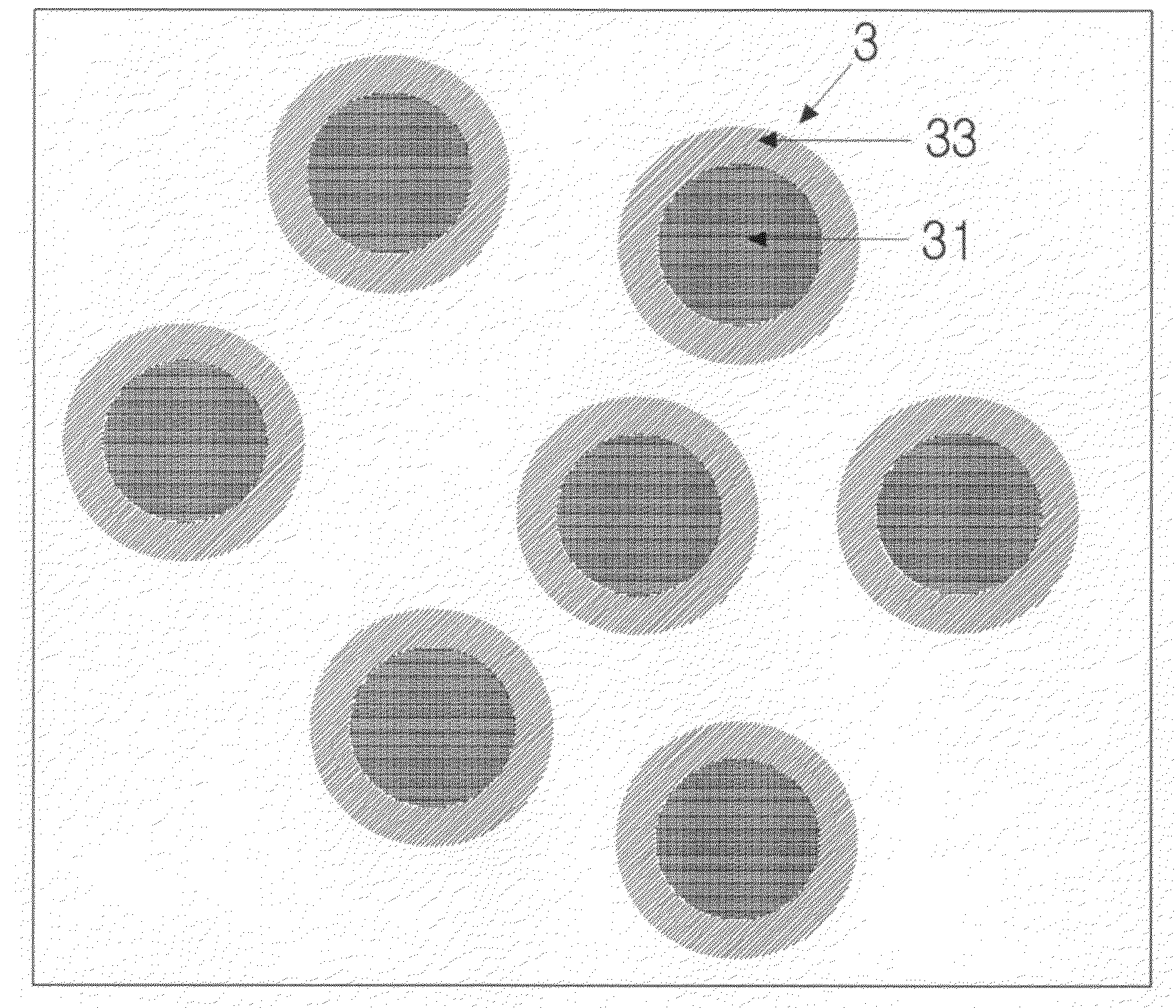

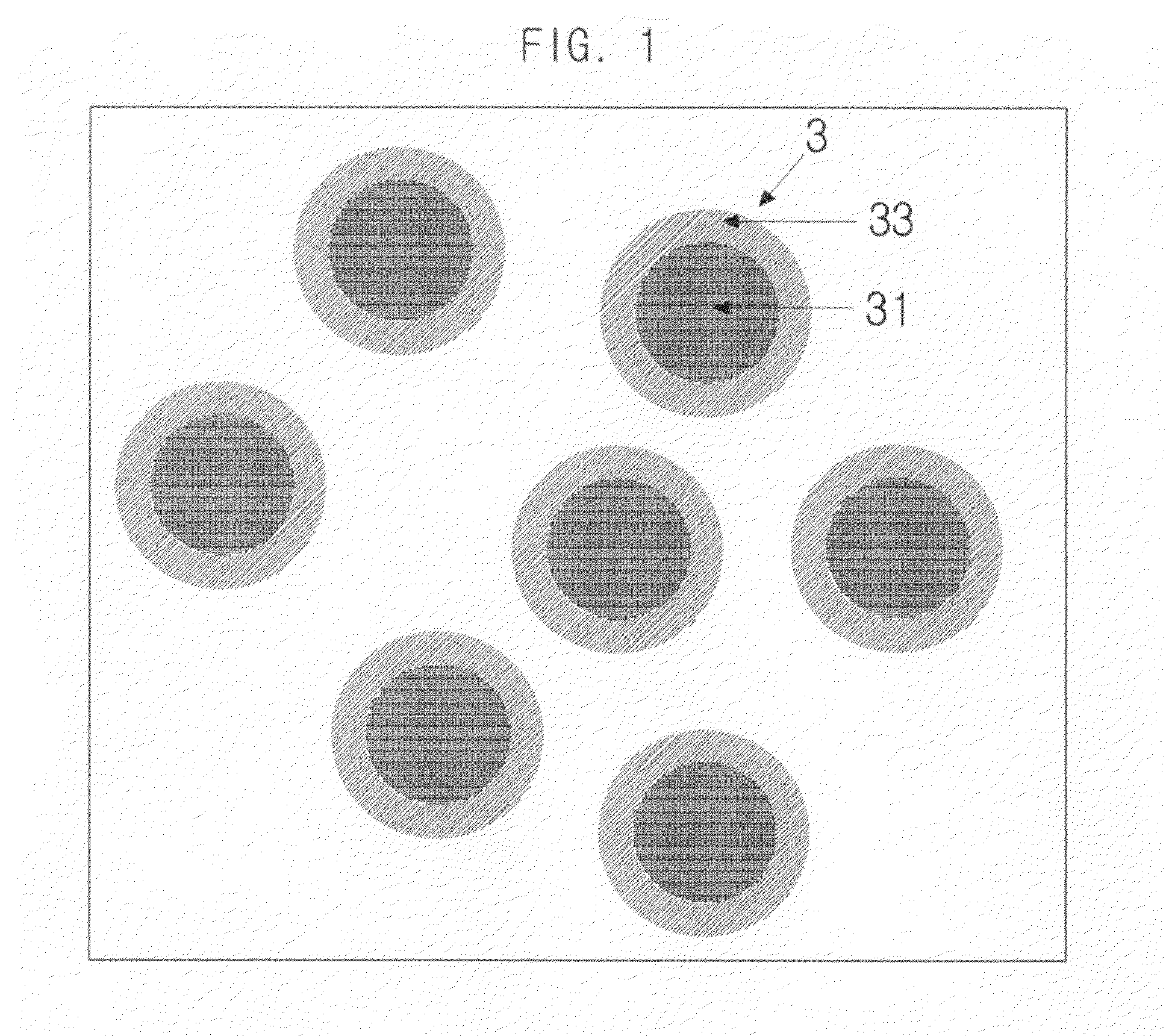

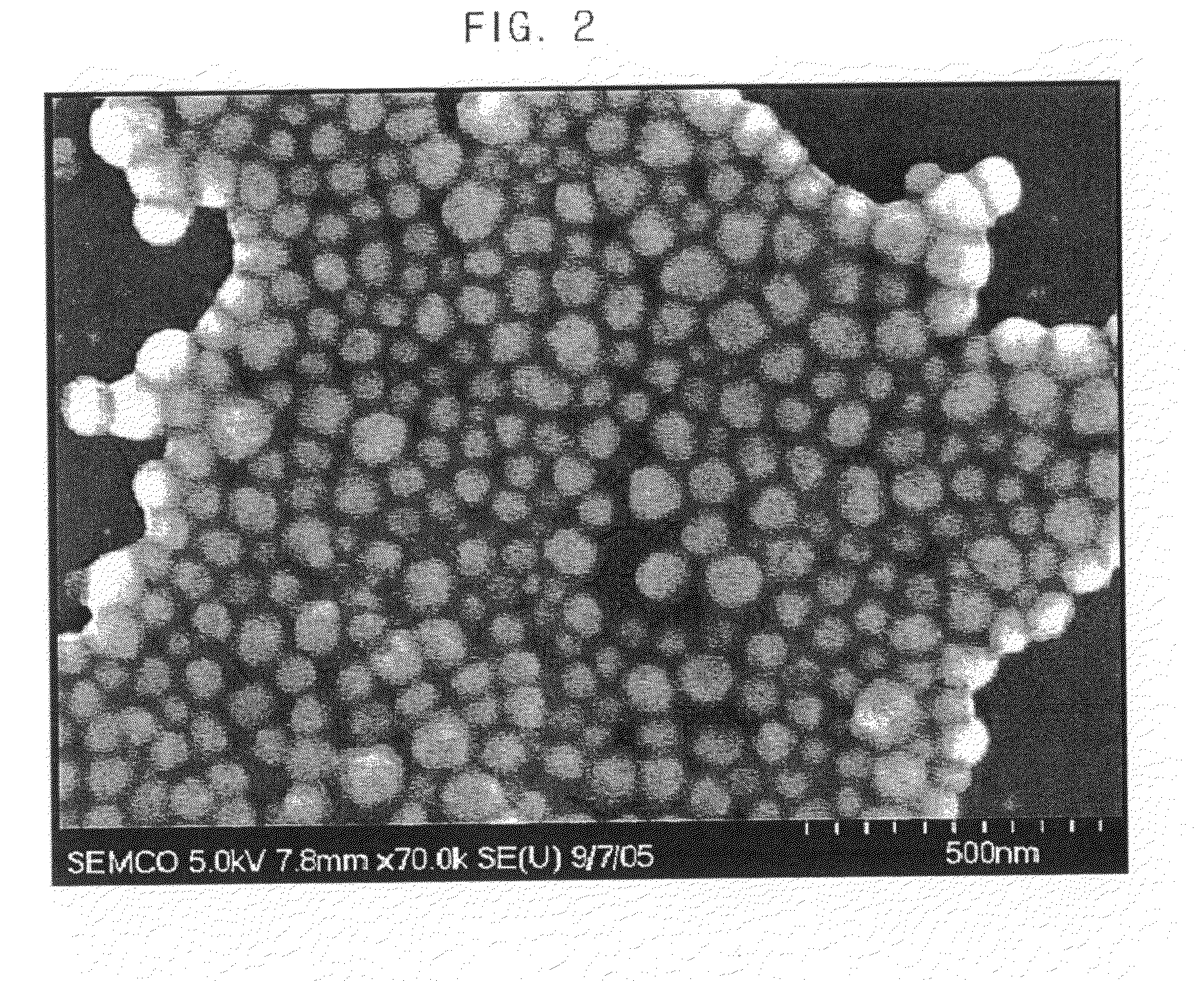

[0068]FIG. 2 is a SEM photo of the metal nanoparticles produced according to this procedure, FIG. 3 is particle distribution of the metal nanoparticles produced according to example 1, FIG. 4 is also a TEM photo of the metal nanoparticles produced according to exam...

example 2

[0069]Oleylamine 50 g, 1-octadecene 50 g, copper acetylacetonate(C5H7CuO2) 20 g and ascorbic acid 15 g were put into a round flask equipped with a condenser and heated to 70° C. for 1 hour. After then, the temperature was raised to 110° C. by a rate of 5° C. / min, and the reaction solution was reacted for 1 hour. After the solution was cooled to 50° C. by air-cooling, 7 g of Ag dodecanate was added and then the temperature was raised to 110° C. by a rate of 5° C. / min, and the reaction solution was reacted for 1 hour at 110° C. After the reaction completed, 300 ml of methanol was added and the nanoparticles were precipitated. These precipitates were washed with methanol more than 3 times and dried at 45° C. in a drying oven.

example 3

[0070]Oleylamine 50 g, xylene 50 g, copper acetylacetonate(C5H7CuO2) 20 g and ascorbic acid 15 g were put into a round flask equipped with a condenser and heated to 70° C. for 1 hour. After then, the temperature was raised to 250° C. by a rate of 5° C. / min, and the reaction solution was reacted for 30 min at 250° C. After the reaction solution was cooled to 50° C. by air-cooling, 7 g of Ag dodecanate was added and then the temperature was raised to 250° C. by a rate of 5° C. / min, and the reaction solution was reacted for 30 min at 250° C. After the reaction completed, 300 ml of methanol was added and the nanoparticles were precipitated. These nanopricipitates were washed with methanol more than 3 times and dried at 45° C. in a drying oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com