Delivery Pump

a technology for moving pumps and pumps, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of affecting the cleaning of the pump, affecting the cleaning effect of the pump, and affecting the reliability of the pump, etc., to achieve rapid product changes, accurate adjustment, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

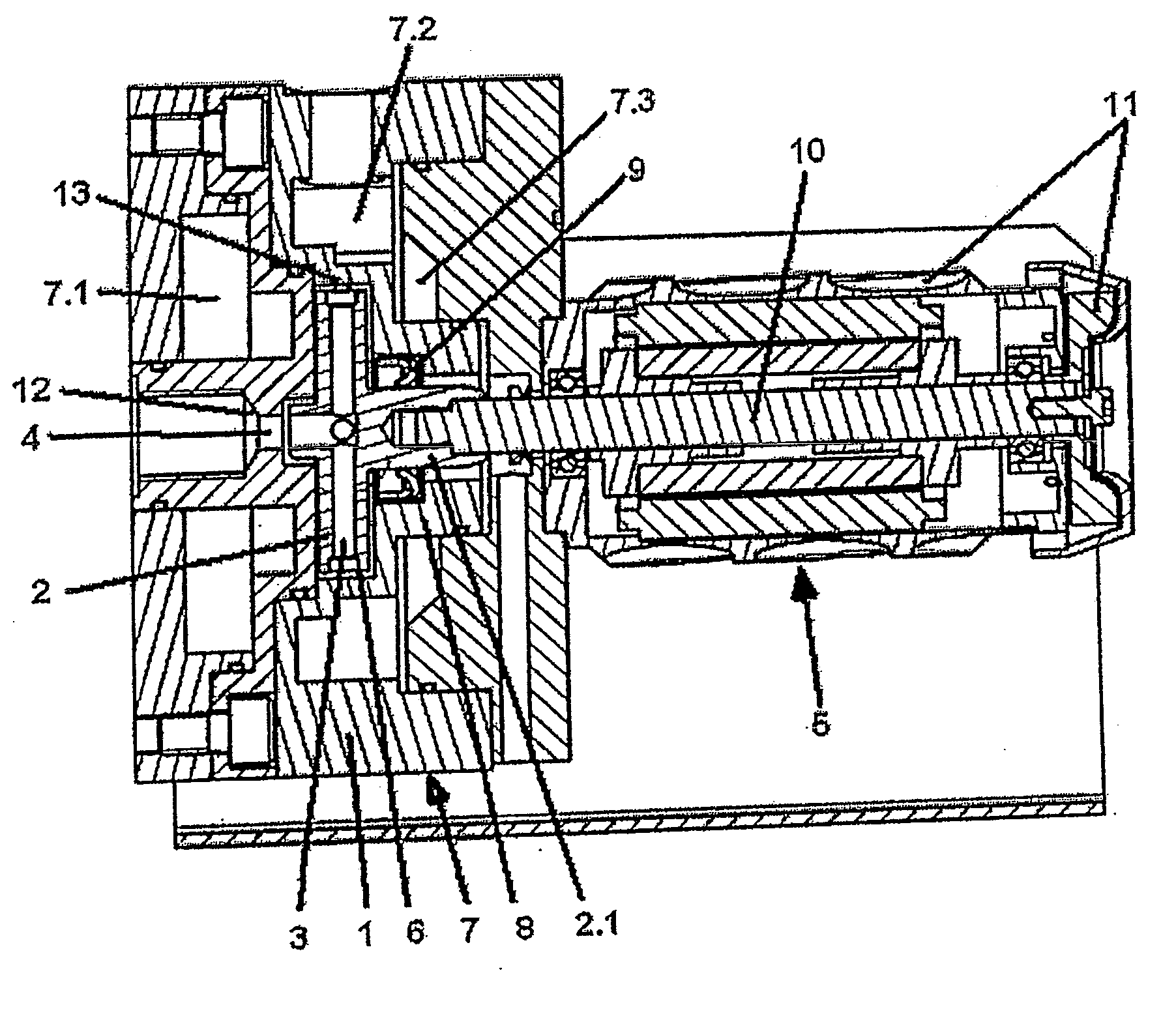

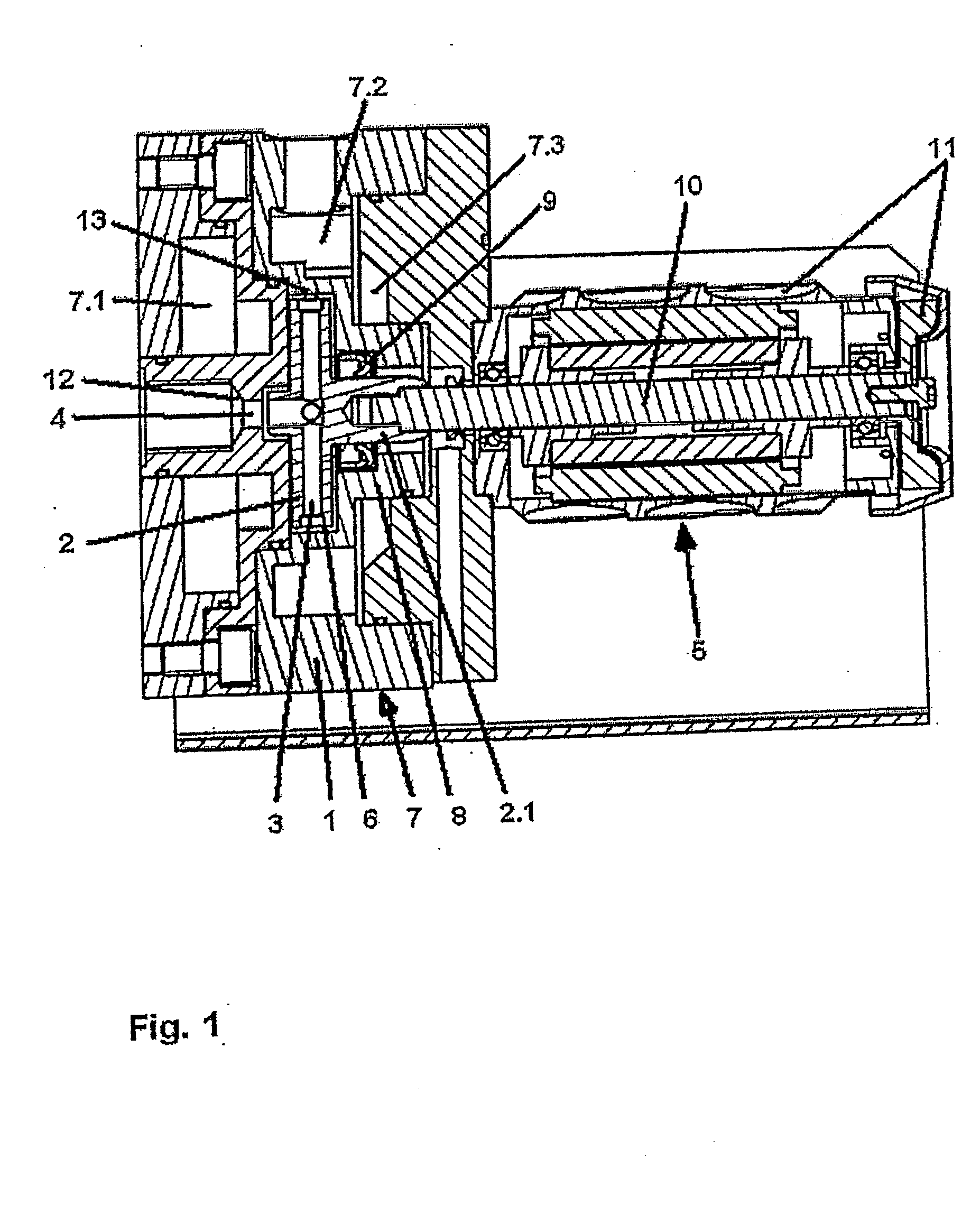

[0026]FIG. 1 illustrates a delivery pump having a single-stage pump construction. A radial impeller 2 of centrifugal type of construction is arranged rotatably in the pump casing 1. The radial impeller 2 has delivery ducts 3 and receives the flow centrally through a pump inlet 4. The radial impeller 2 is connected in a force-transmitting manner to a variable-speed drive 5 and has an outside diameter DLA which may amount to up to 70 mm. The radial impeller rotates in an impeller chamber 6, the inside diameter DLRI of which is designed to be only a maximum of 4% larger than the outside diameter DLA, of the radial impeller 2.

[0027]The pump casing 1 is provided with a thermal control device 7 which in this illustrative embodiment is integrated in the pump casing. Other forms of construction are also possible. Cooling spaces 7.1 to 7.3 surround the impeller chamber 6 and also a seal casing 8 contiguous to the pump casing 1. Within the seal casing 8 is arranged, as a type of shaft seal, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com