Heating and hot water supply apparatus

a technology of hot water supply and heater, which is applied in the direction of domestic hot water supply system, heating types, applications, etc., can solve the problems of insufficient heating in regions, inability to efficiently supply hot water in hot water tanks, and worse heat derivation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

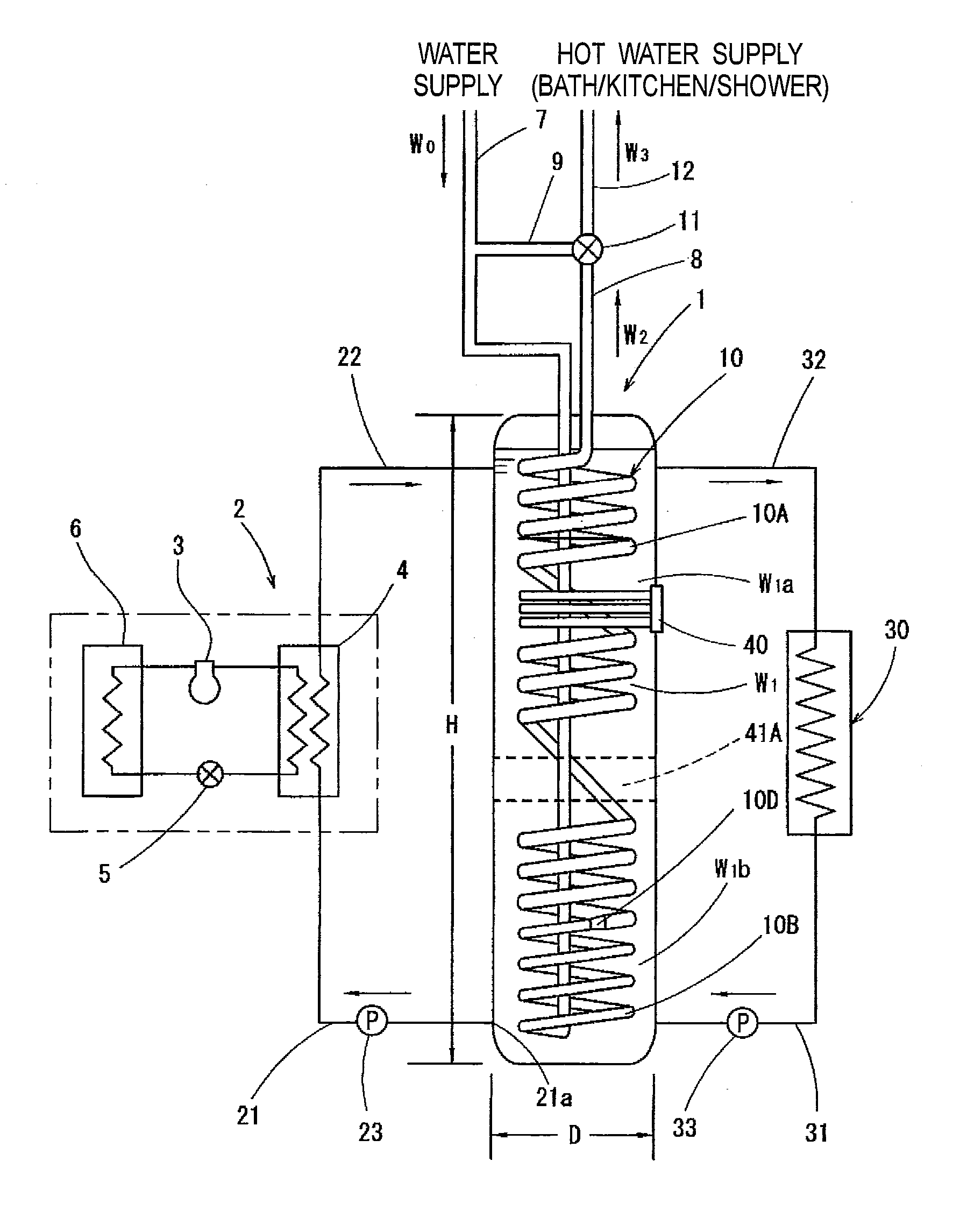

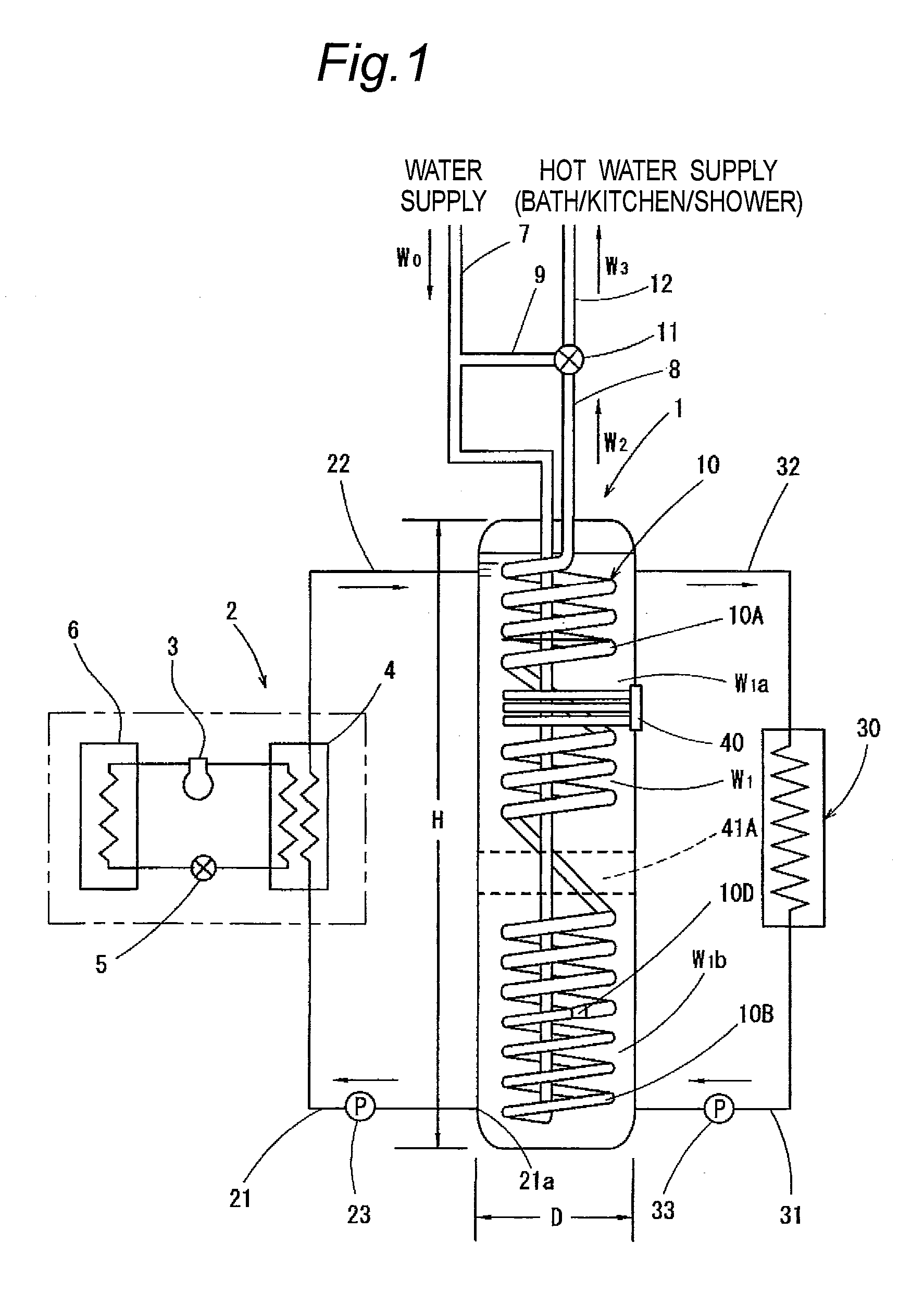

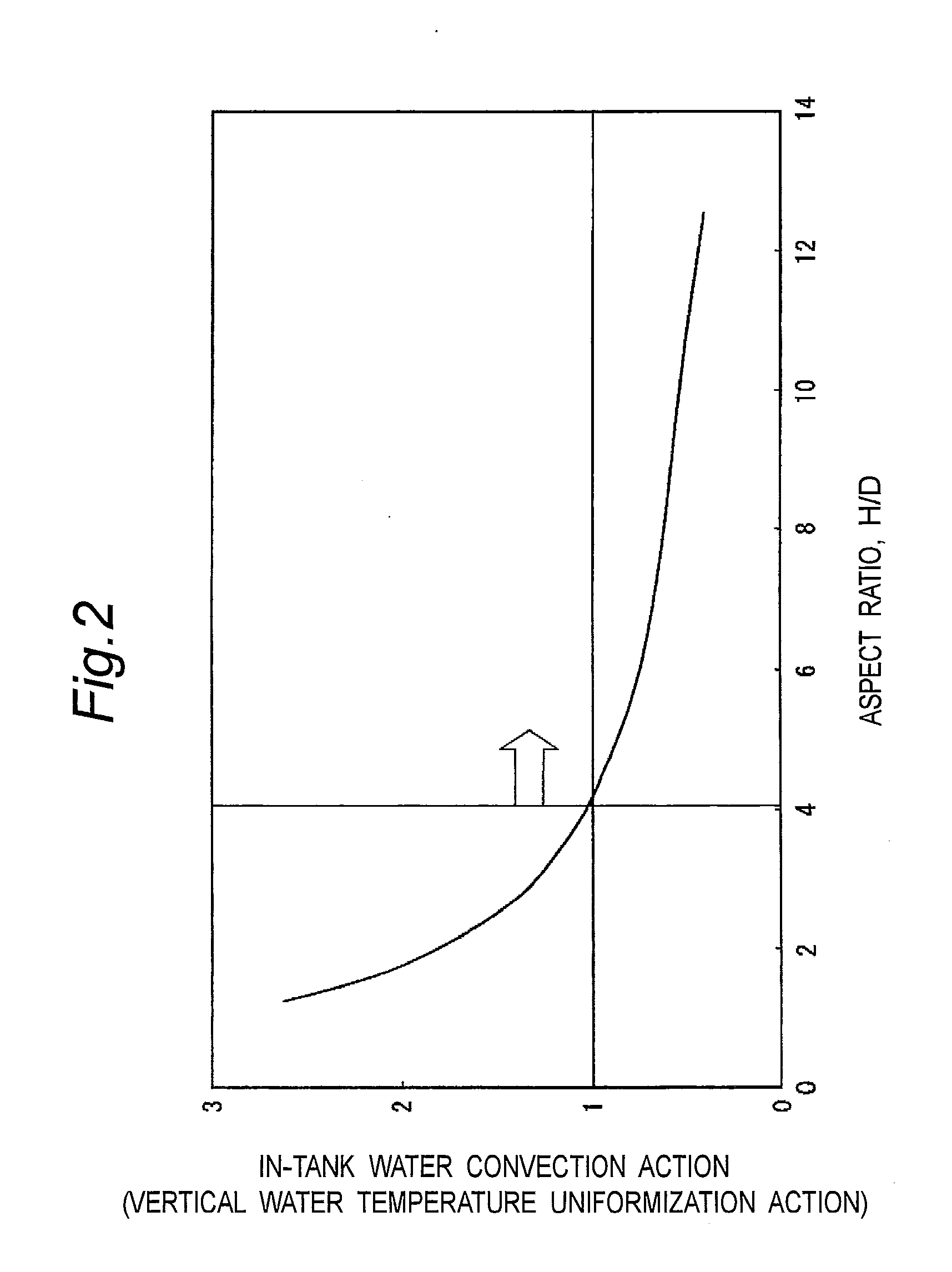

[0034]More specifically, the heating and hot water supply apparatus according to the invention, as illustrated in FIG. 1, includes: a heat pump unit 2 having a compressor 3 for compressing a refrigerant, a radiative heat exchanger 4 for condensing the compressed refrigerant to radiate heat, and an endothermic heat exchanger 6 for evaporating the condensed refrigerant and absorbing heat from the air; and a water storage tank 1 which is connected to the heat pump unit 2 via a lower-position side water pipe 21 and a higher-position side water pipe 22 and in which stored water W1, i.e. hot water heated by the radiative heat exchanger 4 is stored and moreover which is internally provided with an in-tank heat exchanger 10 for performing heat exchange with the stored water W1 to heat flow-through water W2, i.e. supply hot water flowing through the interior of the in-tank heat exchanger 10, wherein the water storage tank aspect ratio (H / D), i.e., a ratio of the inner height H to the inner d...

second embodiment

[0042]Next, with regard to a heating and hot water supply apparatus of a second embodiment, FIG. 3 shows another example of the actualization for facilitating the vertical temperature difference creating action for the stored water W1 in the water storage tank 1 by the in-tank heat exchanger 10. The heating and hot water supply apparatus shown in FIG. 3 is similar to the heating and hot water supply apparatus shown in FIG. 1 in that the water-supply side pipe line 7 running to the in-tank heat exchanger 10 is vertically provided in a straight pipe shape up to a vicinity of the bottom portion within the water storage tank 1 while the range from the lower end of the water-supply side pipe line 7 to the outlet-side pipe line 8 on the exit side is provided by the in-tank heat exchanger 10, which is a coiled tubular member. However, in the heating and hot water supply apparatus shown in FIG. 3, the in-tank heat exchanger 10, which is formed as a coiled tubular member, is made higher in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com