Molded snowshoe with pliable heel contact area

a technology of contact area and snowshoe, which is applied in the field of snowshoes, can solve the problems of reducing sound transmission, mounting traction in an area having flexibility, and causing sound to be distorted, so as to reduce impact force, reduce sound transmission, and avoid sound distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

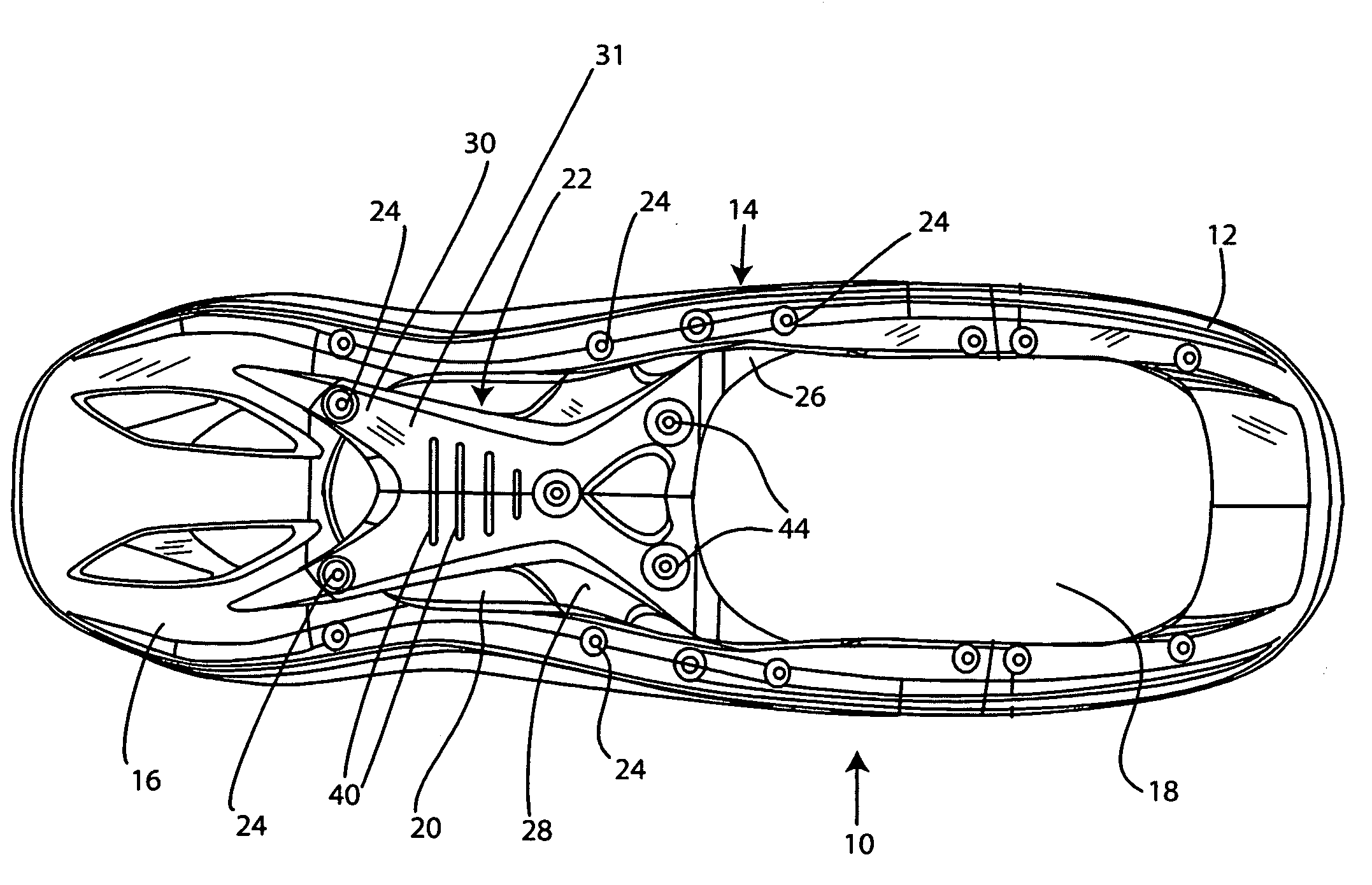

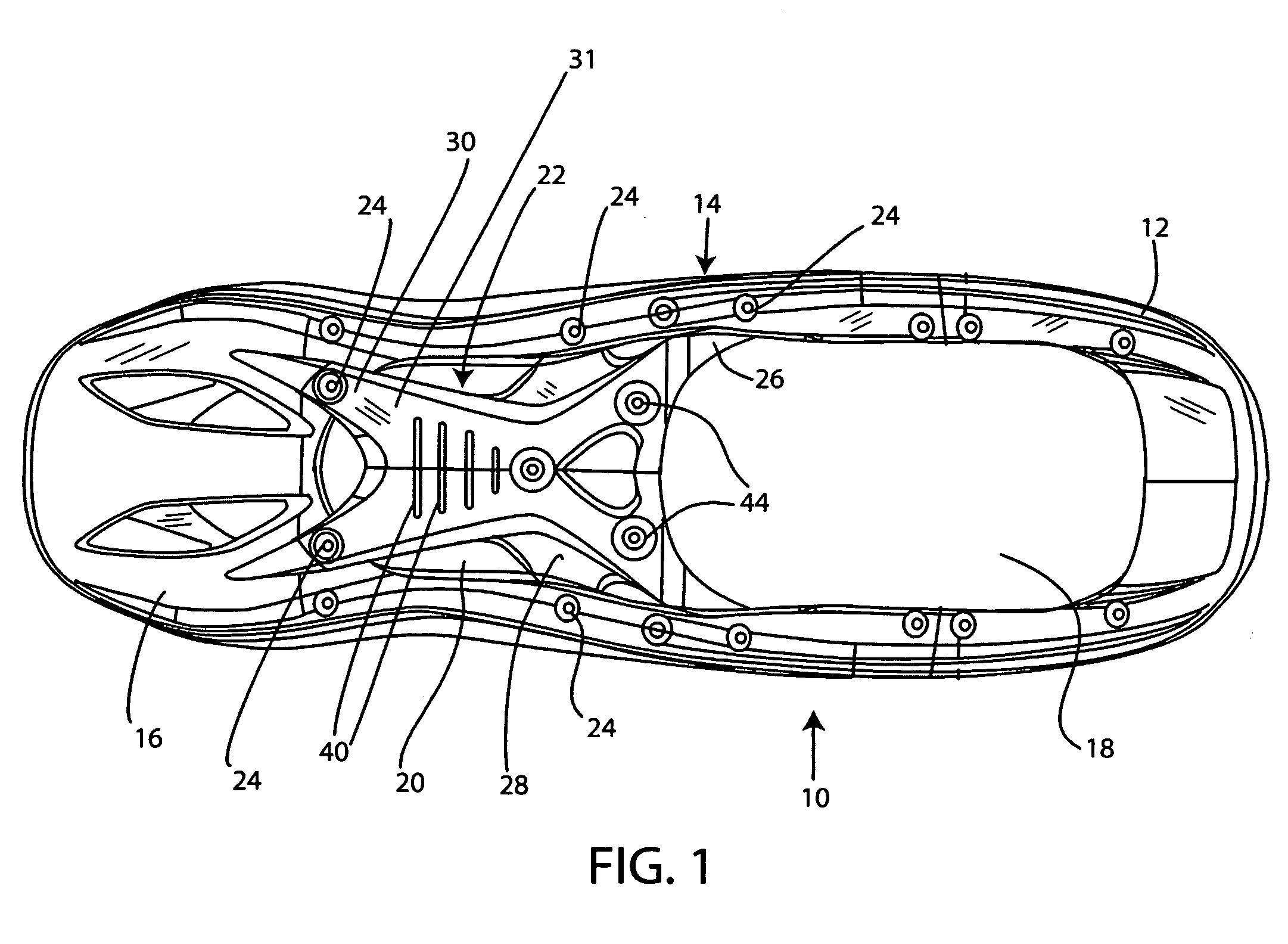

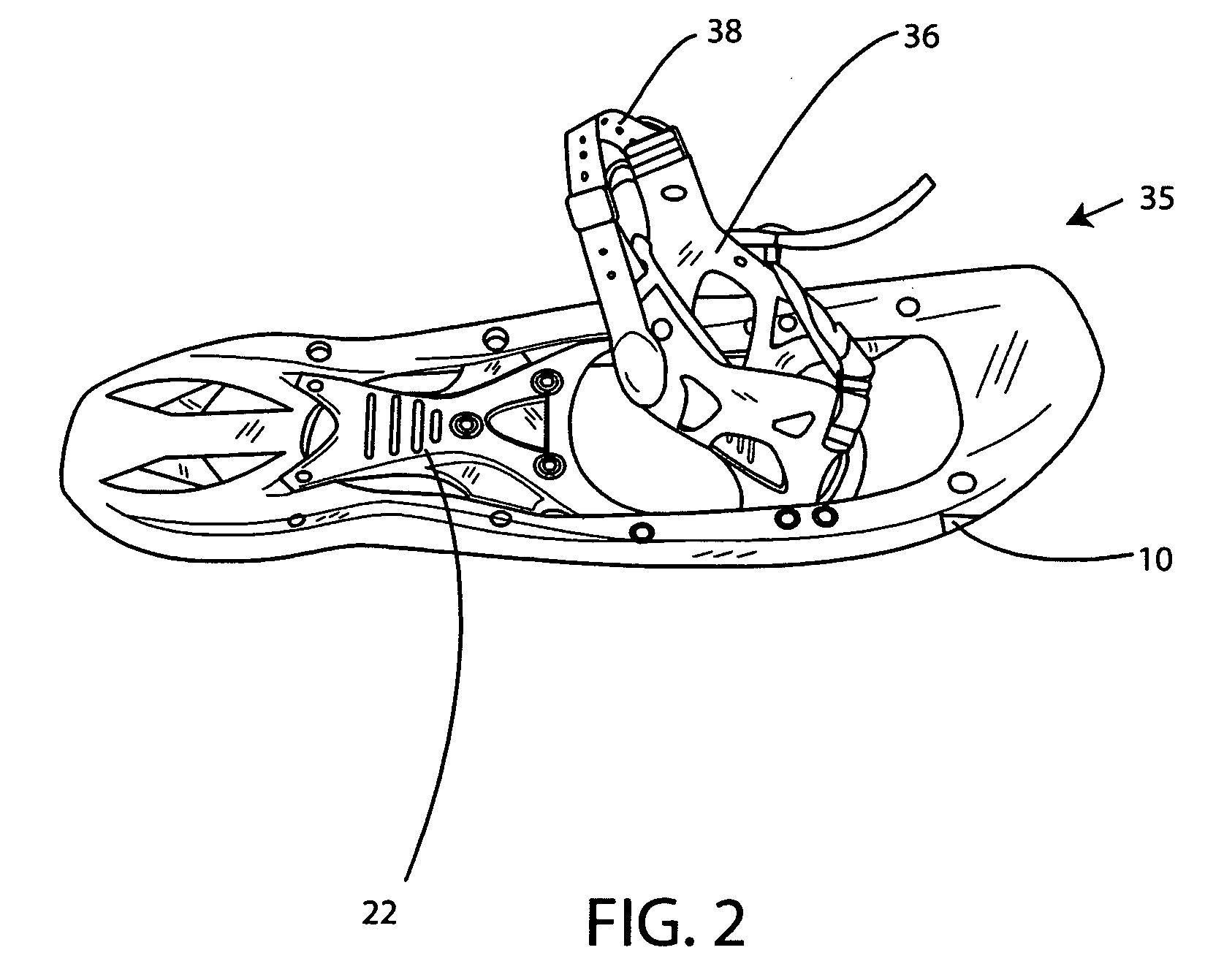

[0019]FIG. 1 is a top view showing a snowshoe body 10 according to the invention, without binding. The snowshoe body is molded of a relatively rigid plastic material, which may be a reinforced composite, examples being polypropylene and nylon. Preferred thickness through most of the snowshoe body is about 3.3 mm, or a range of about 3-4 mm. As seen in the drawing, the molded snowshoe body includes a nose portion 12, a central portion 14 and a tail 16. The snowshoe body is molded with a large open area at 18 and continuing back to the region 20 in the drawing. Although this is shown as one large open area, it could instead be embodied as a forward open area generally at 18 and a rear, heel strike region open area generally at 20. The forward open area is provided for a boot binding which is permitted pitch pivoting movement, as described below with reference to FIGS. 2 and 3. The heel area opening, generally at 20, is provided for the soft strike heel feature described above.

[0020]In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com