Automotive exhaust system

a technology for exhaust systems and automobiles, applied in the direction of exhaust treatment, machines/engines, gas passages, etc., can solve the problems of preventing efficient escape of exhaust gases from within the cylinder, affecting vehicle performance, fuel consumption, efficiency and power, and affecting vehicle performance, etc., to achieve quick and efficient expulsion of exhaust gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

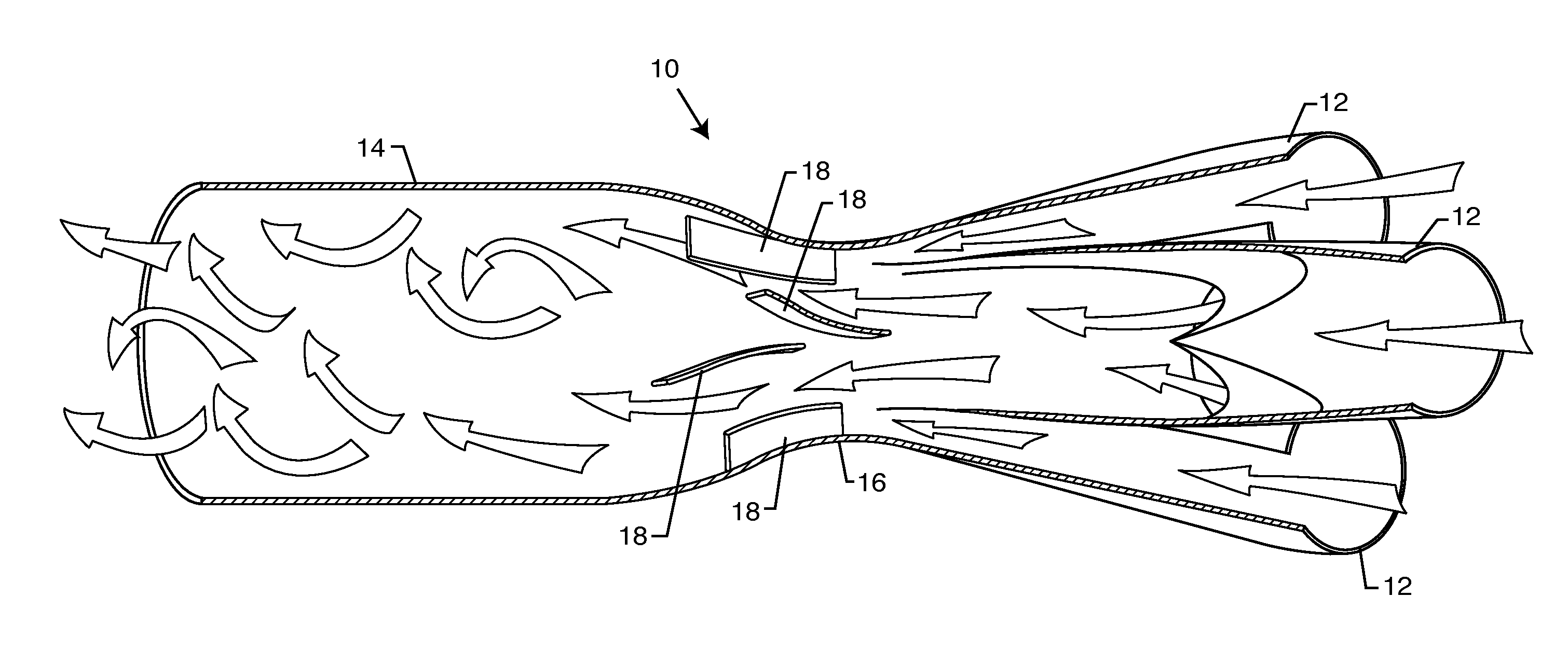

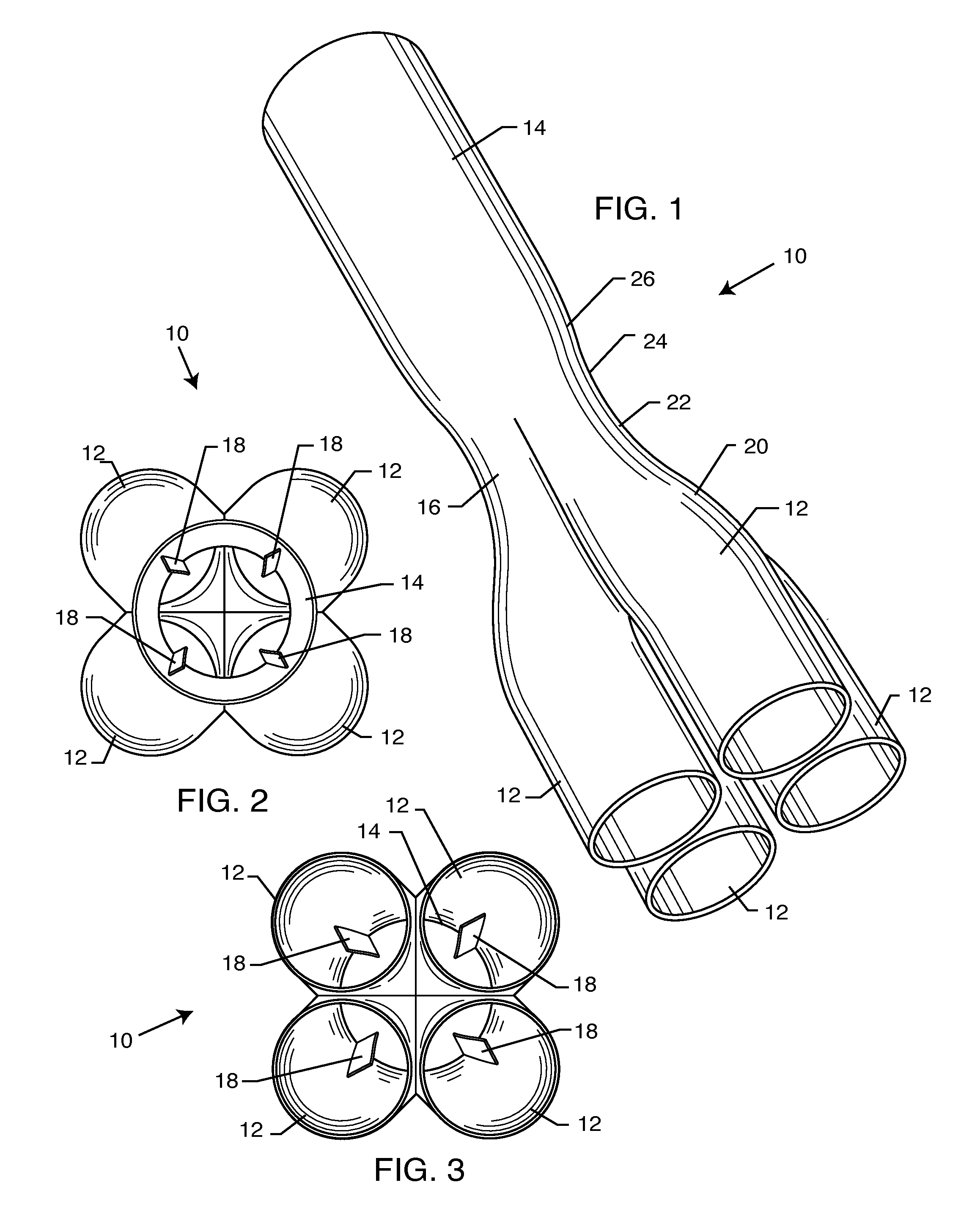

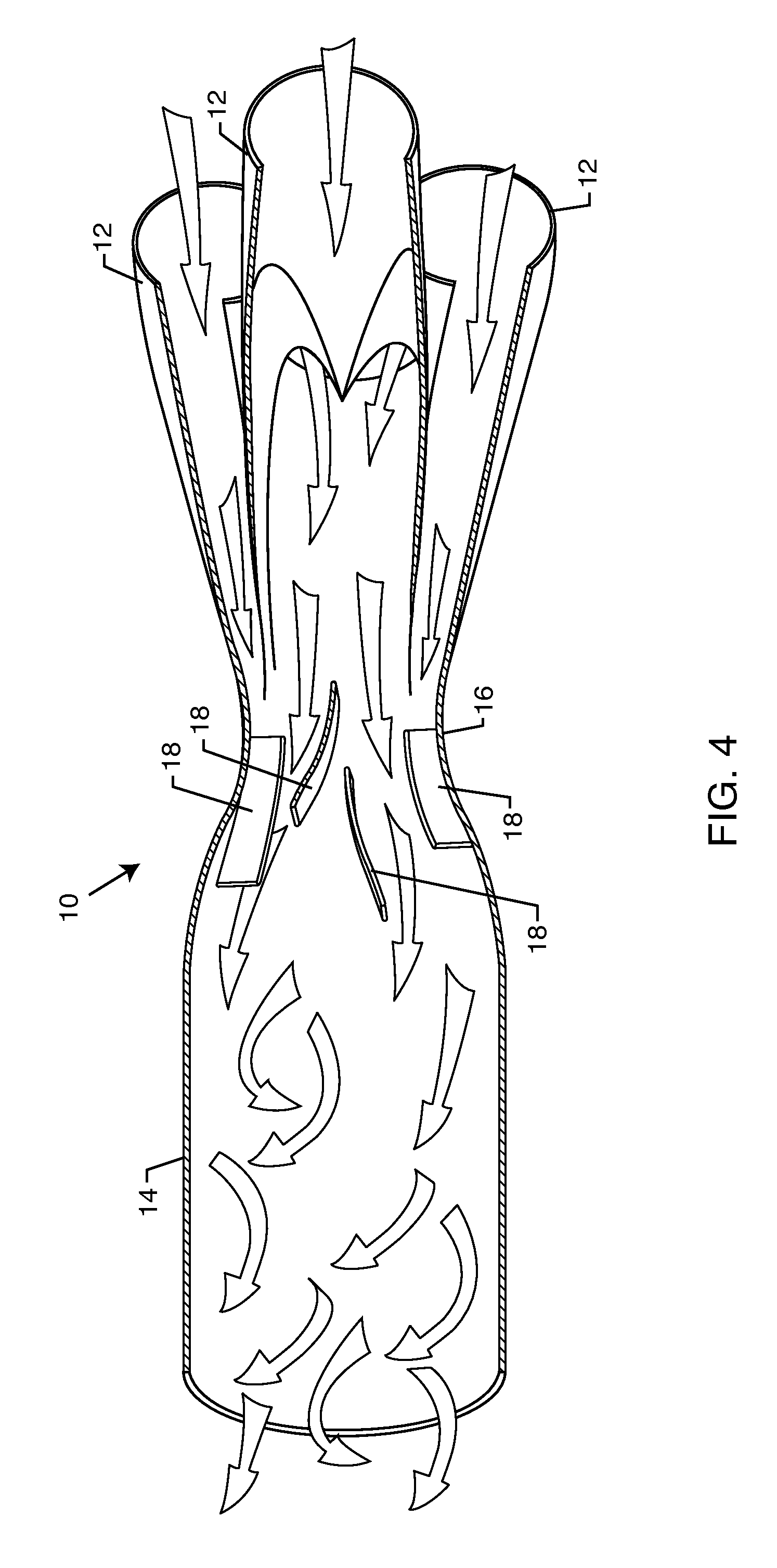

[0015]As shown in the drawings for purposes of illustration, the present invention for an improved automotive exhaust system is referred to generally by the reference number 10. The improved automotive exhaust system 10 generally includes a plurality of exhaust pipes 12 that feed into a collector 14 through a venturi 16. FIG. 1 illustrates four exhaust pipes 12 converging into a single collector 14. Other embodiments may include any one of a number of plurality of exhaust pipes 12 that feed into a single collector 14, such as two, three, five, etc., in accordance with the present invention. In this respect, the exhaust pipes 12 are shown in FIG. 1 sectioned off from an exhaust header for purposes of describing the improved automotive exhaust system 10 of the present invention. A person of ordinary skill in the art will readily recognize that the exhaust pipes 12 extend back into the exhaust header that couples to the IC engine piston cylinders. That is, during the exhaust stroke in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com