High-pressure generation device

a generation device and high-pressure technology, applied in the direction of positive displacement liquid engines, pumping pumps, machines/engines, etc., can solve the problems of complex structure, high cost in most cases, and problems such as upsizing, and achieve the effects of simple structure, low cost, and relatively easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]Hereinafter, the high-pressure generation device of the embodiments provided in accordance with the present invention will be described with reference to the drawings.

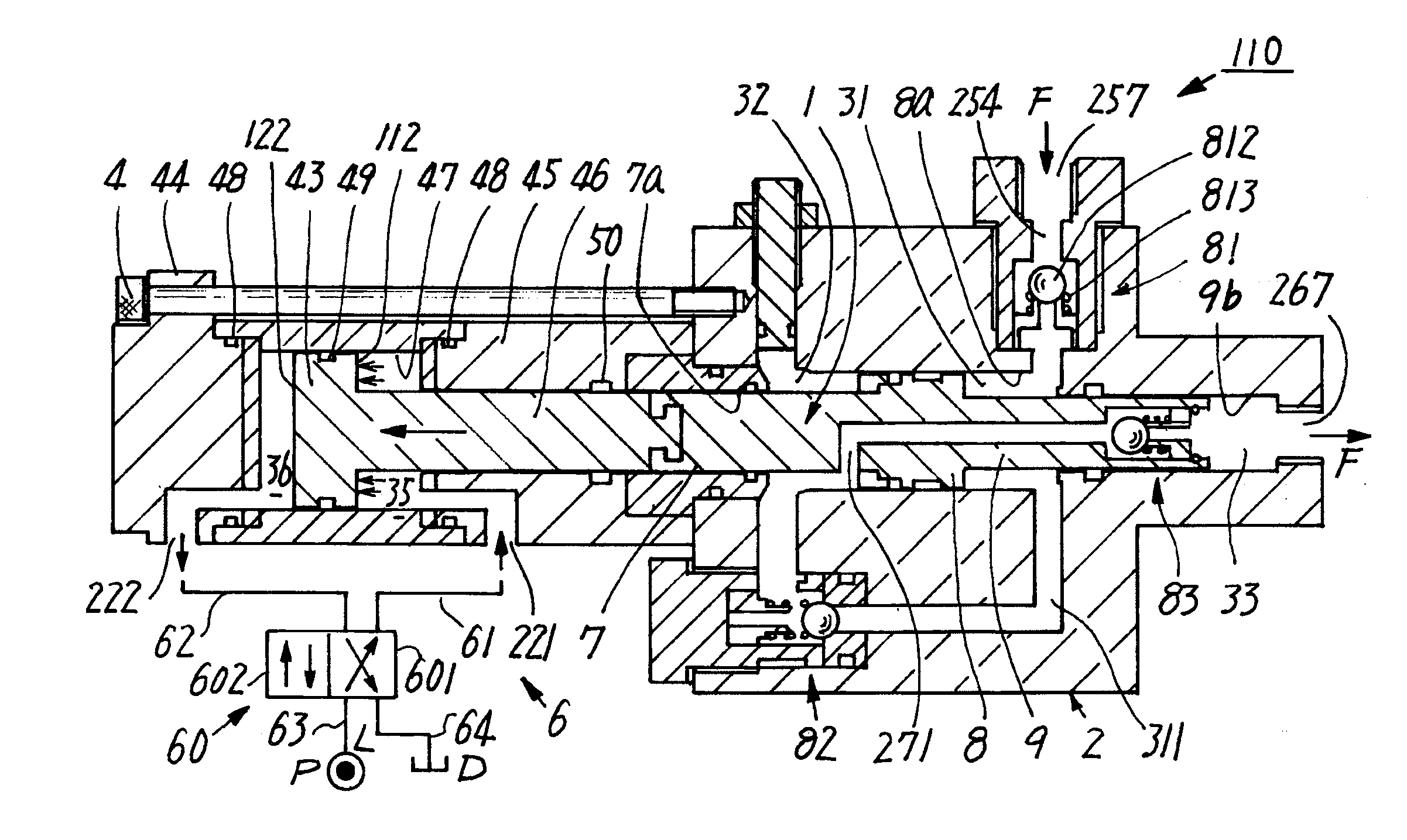

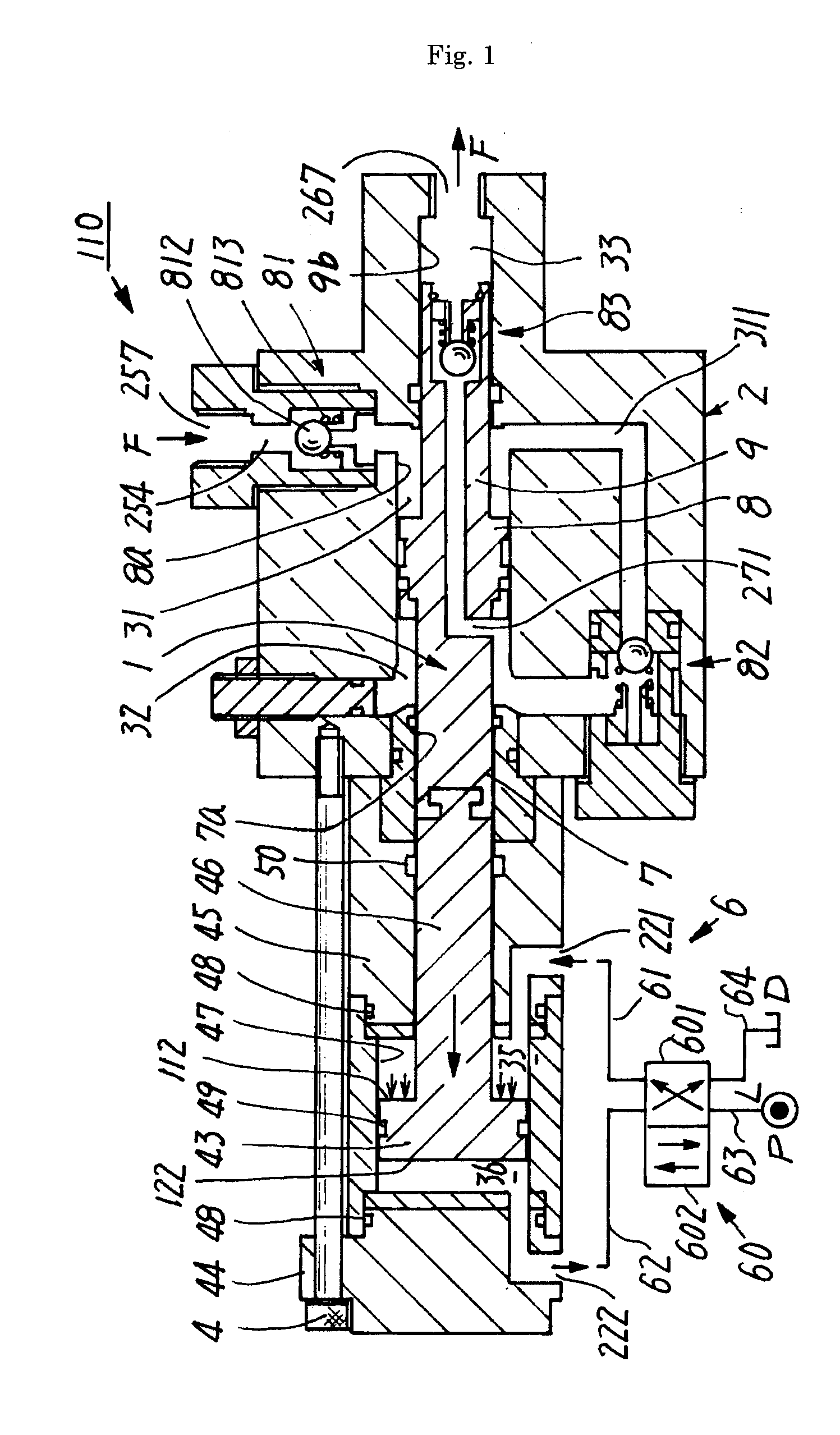

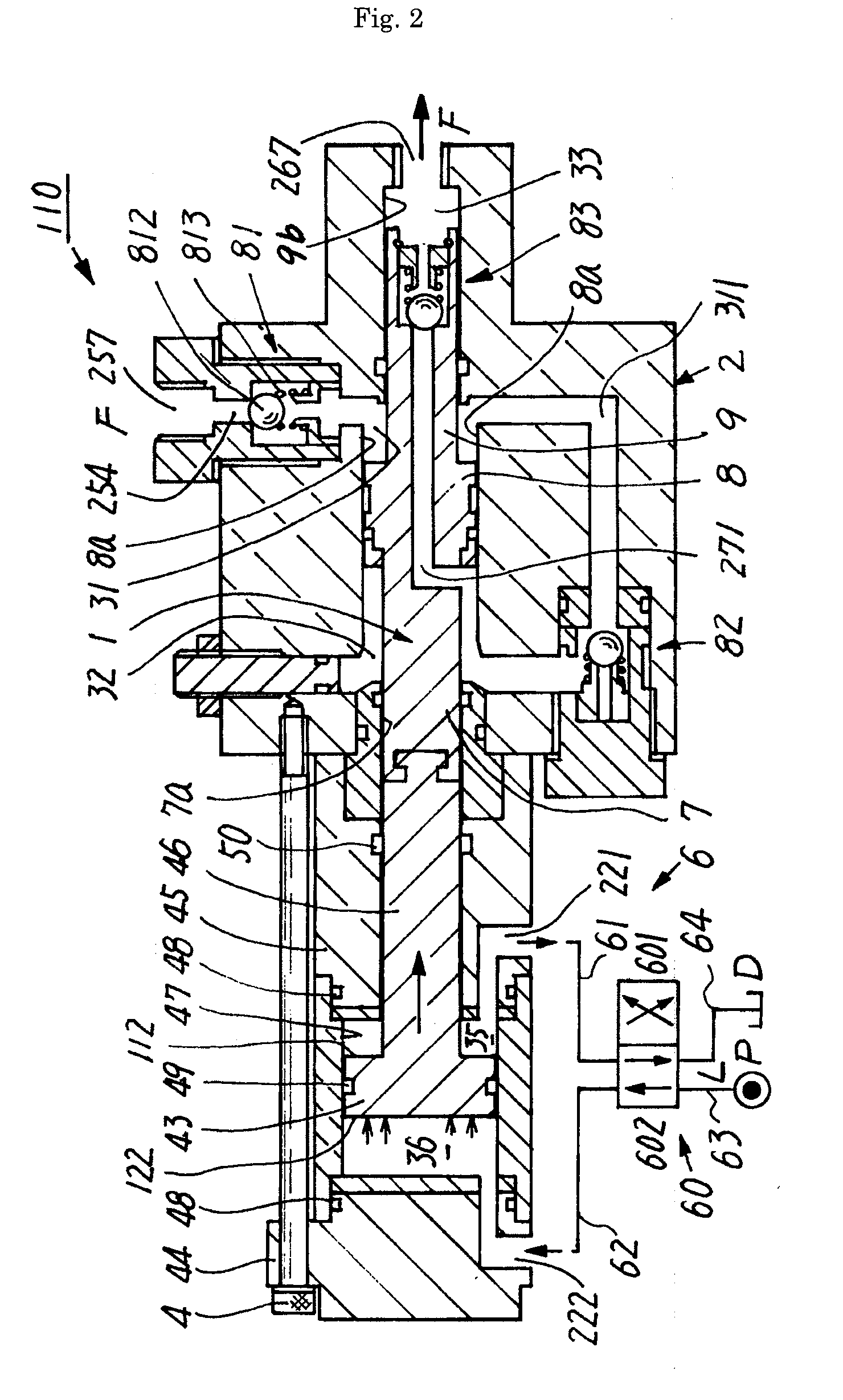

[0048]FIG. 1 and FIG. 2 are cross-sectional views showing examples of the high pressure generation device in accordance with one embodiment of the present invention.

[0049]As shown in FIG. 1 and FIG. 2, the high pressure generation device 110 in accordance with one embodiment of the present invention is provided with three pressure chambers, that is, a first pressure chamber 31, a second pressure chamber 32, and a third pressure chamber 33 for performing a pumping operation to pressurize and discharge liquid in a space in which a piston 1 fitted into a housing 2 reciprocates, an intake port 257 for drawing the liquid from the outside into the first pressure chamber 31, a first flow passage 254 for communicating the intake port 257 and the first pressure chamber 31, a second flow passage 311 for communicating the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com