Method for making composite sputtering targets and the tartets made in accordance with the method

a composite sputtering target and composite technology, applied in the direction of thin material processing, transportation and packaging, etc., can solve the problems of significant material loss in the recycling process, impractical sputtering of the target material further, etc., to reduce the amount of precious metal containing sputtering material, reduce the cost of ownership of the sputtering target assembly, and increase the material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

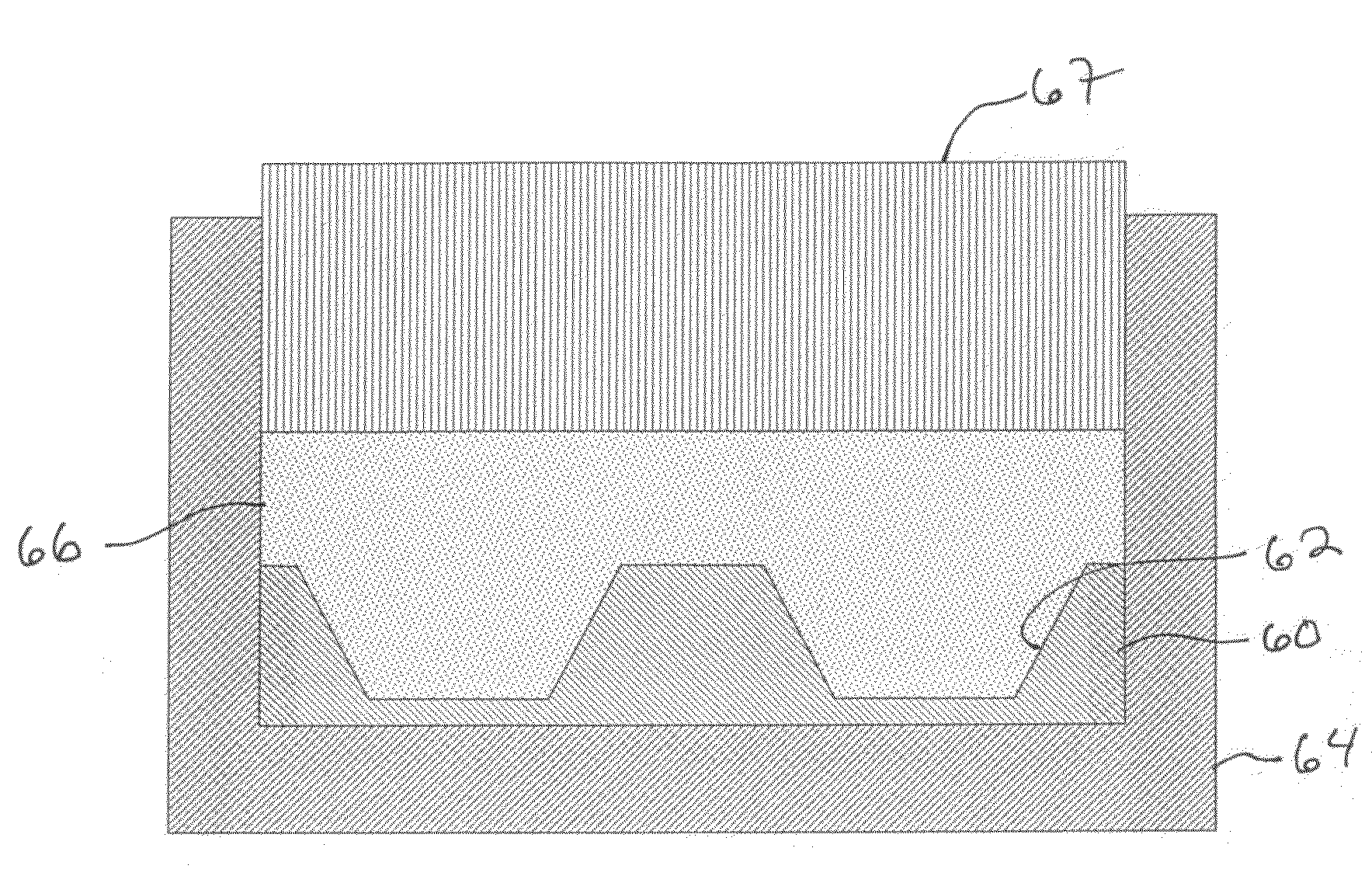

[0031]A 2.03″ diameter by 0.31″ thick circular Ru composite sputtering target was fabricated with a Mo backing plate using the disclosed invention. Using a lathe, a 2.03″ diameter by 0.25″ thick piece of Mo was machined in such a way as to provide a cavity concentric with the diameter of the Mo piece with a depth of 0.115″ deep and top diameter of 1.84″ and a bottom diameter of 1.55″ (forming a frustum shape). The machined Mo piece was placed into a graphite hot press die and 100 grams of Ru powder was poured into the die cavity so as to fill the cavity in the Mo piece and cover the top of it. A graphite die ram was then placed into the die cavity and lowered onto the top of the Ru powder.

[0032]The die assemblage was subsequently placed in a hydraulic press and pressed to a few hundred pounds of load to pre-compress the Ru powder. Then the die assemblage was placed into a vacuum hot press and processed at 1525° C. for 0.5 hours at 500 psi at a vacuum level of 200 mTorr. After hot pr...

example 2

[0036]A 2.03″ diameter by 0.31″ thick circular Ru composite sputtering target was fabricated with an Nb backing plate using the disclosed invention. Using a lathe, a 2.03″ diameter by 0.25″ thick piece of Nb was machined in such a way as to provide a cavity concentric with the diameter of the Nb piece with a depth of 0.115″ deep and top diameter of 1.84″ and a bottom diameter of 1.55″ (forming a frustum shape). The machined Nb piece was placed into a graphite hot press die and 100 grams of Ru powder was poured into the die cavity so as to fill the cavity in the Mo piece and cover the top of it. A graphite die ram was then placed into the die cavity and lowered onto the top of the Ru powder.

[0037]The die assemblage was subsequently placed in a hydraulic press and pressed to a few hundred pounds of load to pre-compress the Ru powder. Then the die assemblage was placed into a vacuum hot press and processed at 1525° C. for 0.5 hours at 500 psi at a vacuum level of 200 mTorr. After hot p...

example 3

[0040]A 2.03″ diameter by 0.31″ thick circular Ru composite sputtering target was fabricated with a Ta backing plate using the disclosed invention. Using a lathe, a 2.03″ diameter by 0.25″ thick piece of Ta was machined in such a way as to provide a cavity concentric with the diameter of the Ta piece with a depth of 0.115″ deep and top diameter of 1.84″ and a bottom diameter of 1.55″ (forming a frustum shape). The machined Ta piece was placed into a graphite hot press die and 100 grams of Ru powder was poured into the die cavity so as to fill the cavity in the Ta piece and cover the top of it. A graphite die ram was then placed into the die cavity and lowered onto the top of the Ru powder.

[0041]The die assemblage was subsequently placed in a hydraulic press and pressed to a few hundred pounds of load to pre-compress the Ru powder. Then the die assemblage was placed into a vacuum hot press and processed at 1525° C. for 0.5 hours at 500 psi at a vacuum level of 200 mTorr. After hot pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com